The method of palletizing is simple and convenient to adjust.It can be realized in man-machine inter face hill.At the same time, the systems suitable for both carton and film-wrapped products.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HZM

-

Dimension(L*W*H):

-

4500*3800*2700mm

-

Weight:

-

4500 KG

-

Product name:

-

Automatic Palletizing Machinery

-

Keyword:

-

Boxes Palletization Machine

-

Usage:

-

Water Juice Beverage Production Line

-

After Warranty Service:

-

Cnline Support

-

Suitable for:

-

Bottles Cans Box Cartons

-

Packing speed:

-

10~50pcs/min

-

Advantage:

-

Saving Time

-

Feature:

-

Simple Operation Easy Maintenanc

-

Main Function:

-

carton box placing and palletizing

Quick Details

-

Application:

-

Food, Beverage

-

Packaging Material:

-

Plastic

-

Voltage:

-

380V 50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HZM

-

Dimension(L*W*H):

-

4500*3800*2700mm

-

Weight:

-

4500 KG

-

Product name:

-

Automatic Palletizing Machinery

-

Keyword:

-

Boxes Palletization Machine

-

Usage:

-

Water Juice Beverage Production Line

-

After Warranty Service:

-

Cnline Support

-

Suitable for:

-

Bottles Cans Box Cartons

-

Packing speed:

-

10~50pcs/min

-

Advantage:

-

Saving Time

-

Feature:

-

Simple Operation Easy Maintenanc

-

Main Function:

-

carton box placing and palletizing

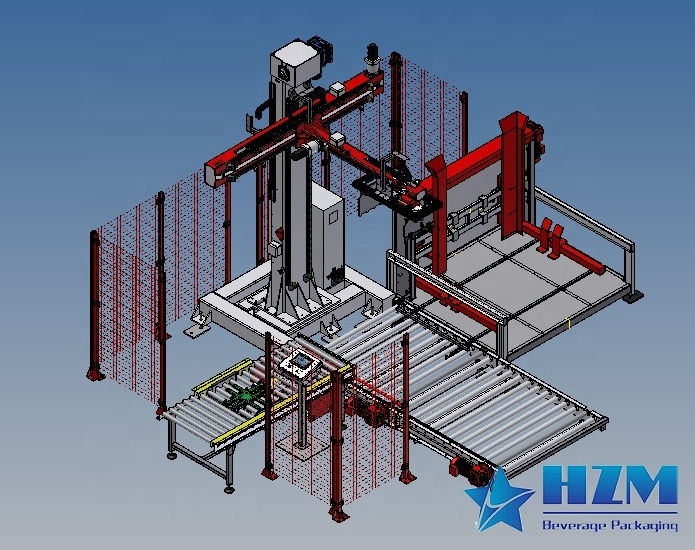

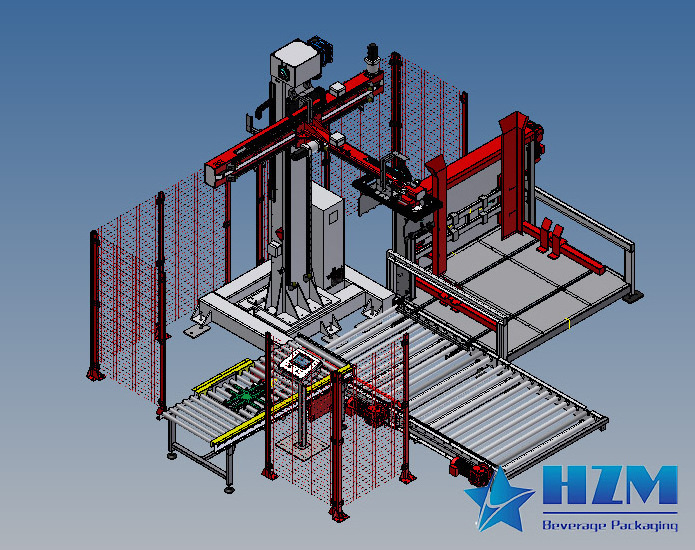

PRODUCT OVERVIEW

AUTOMATIC PALLETIZING MACHINE

This machine is mainly used in various high speed production line palletizing and storage.It uses side-entry box mode, which covers small area, has more advanced structure, more portable and stable movement, and low energy consumption.

PRODUCT DESCRIPTION

ROBOT PALLETIZING MACHINE

1.Robot palletizing takes small place and which is convenient to factory layout.

2.In the life of robot, there maybe adding or changing of products,Robot just needs to modify some program to fit new products.

3.One robot unit can palletize more lines at the same time, or more robots palletize more lines so that improved the efficiency and stability.

4,6bearing pallectizing robot normal working power is 22KW

5.As for the application, here is specially developed Pallet.Tech software bag, which can be loaded offline to robot computer with out programming.

6.Robot adopts Modular design, which is based on PC and Window XP opening system, also easily to Expansion and integration. You can find the chance of using during robot using life.

7.Robot average faults interval time is as long as 70,000 hours(8.0year), and the using life is more than 15 years.

8.High manufacturing efficiency: During working progress, start and stop slow and steady, middle part running fast to reduce non-working time and improve manufacturing efficiency.

9.Easily operation: This machine is full automatically, which can auto adjust running speed and keep same step with manufacturing line.

10.Reasonable structure: This machine is consisted of machinery structure 、reliable pneumatic device and advanced electronic control technology,advanced and easy.

11.Safety and reliable: This machine also has photoelectric safety protection devices except protection cover、net, when the operator steps to dangerous area, the machine will auto stop.

12.This machine qualified hygiene requirements: low noise and adopted non-lubrication pneumatic components to avoid oil pollution.

2.In the life of robot, there maybe adding or changing of products,Robot just needs to modify some program to fit new products.

3.One robot unit can palletize more lines at the same time, or more robots palletize more lines so that improved the efficiency and stability.

4,6bearing pallectizing robot normal working power is 22KW

5.As for the application, here is specially developed Pallet.Tech software bag, which can be loaded offline to robot computer with out programming.

6.Robot adopts Modular design, which is based on PC and Window XP opening system, also easily to Expansion and integration. You can find the chance of using during robot using life.

7.Robot average faults interval time is as long as 70,000 hours(8.0year), and the using life is more than 15 years.

8.High manufacturing efficiency: During working progress, start and stop slow and steady, middle part running fast to reduce non-working time and improve manufacturing efficiency.

9.Easily operation: This machine is full automatically, which can auto adjust running speed and keep same step with manufacturing line.

10.Reasonable structure: This machine is consisted of machinery structure 、reliable pneumatic device and advanced electronic control technology,advanced and easy.

11.Safety and reliable: This machine also has photoelectric safety protection devices except protection cover、net, when the operator steps to dangerous area, the machine will auto stop.

12.This machine qualified hygiene requirements: low noise and adopted non-lubrication pneumatic components to avoid oil pollution.

GANTRY PALLETIZING MACHINE

1.Full auto mechanical type palletizer is used to put cartons on pallets systematically and then push out, using lift moving to warehouse.

2.This equipment adopts PLC+ touch screen control to realize intelligent operation and management. It can save lots of manual works.

3.Adopting touch screen operation to realize human-machine dialogue, which can show capacity, faults position and reason using PLC (SIEMENS) to control carton position, pallets levels and so on.

4.Adopting FENNER company belt, which is hard enough, high precision, stable conveying.

5.Adopting JAPAN SMC pneumatic components and cylinders.

6.Touch screen we use SIEMENS,

7.Safety door is equipped with sensor device, when the door is open the machine will stop.

8.Palletizing type adjust is easy, which can be realized on screen. It is stable running and high efficiency.

9.Carton supply system using brake motor control, promising right position.

10.Pallet place is big enough, which can contain 12-15 empty pallets, automatic supply pallets.

11.Motor, reducer all using Germany sew company products.

12.No need to change anything, realizing different size palletizing.

13.Noise is less than 65 db, match International standard.

2.This equipment adopts PLC+ touch screen control to realize intelligent operation and management. It can save lots of manual works.

3.Adopting touch screen operation to realize human-machine dialogue, which can show capacity, faults position and reason using PLC (SIEMENS) to control carton position, pallets levels and so on.

4.Adopting FENNER company belt, which is hard enough, high precision, stable conveying.

5.Adopting JAPAN SMC pneumatic components and cylinders.

6.Touch screen we use SIEMENS,

7.Safety door is equipped with sensor device, when the door is open the machine will stop.

8.Palletizing type adjust is easy, which can be realized on screen. It is stable running and high efficiency.

9.Carton supply system using brake motor control, promising right position.

10.Pallet place is big enough, which can contain 12-15 empty pallets, automatic supply pallets.

11.Motor, reducer all using Germany sew company products.

12.No need to change anything, realizing different size palletizing.

13.Noise is less than 65 db, match International standard.

COLUMN TYPE PALLETIZING MACHINE

1.The automatic rope making technology can roll up a circle of film rope and attach it to the pallet to fix the goods. This ensures that the goods will not slip out of the pallet during transportation.

2.

The slewing support chassis can effectively improve the load-bearing capacity of the chassis, and the maximum load-bearing capacity of the slewing support chassis can reach 3000KG;

3.

The service life is more than 3 times that of the traditional chain drive type in-line winding machine chassis.

4.The new film breaking system of the intelligent on-line winding machine completely solves the problem of the wrapping film falling off at the tail of the traditional wrapping machine after the film is broken, so that the film breaking film system is integrated,and the tail wrapping film is perfectly combined with the tray.

APPLICATION RANGE

MORE PRODUCTS

Why Choose HZM

Huazhen Machinery (HZM) Co.,Ltd. is located in Suzhou City. It has an international standard plant with an area of about 10,000square meters. It is a comprehensive professional supplier of liquid beverage packaging machinery,which integrates development, manufacture and sales. It has successively introduced several modern CNC processing equipment from the United States,Japan and other countries and regions. At present,it has about 50 million fixed assets.The product quality not only meets the requirements of the national machinery industry,also achieves CE/ISO 9001:2015 and other international quality management system certification level. The company also has a set of strict and perfect quality inspection standards,which is higher than the national industry requirements.At the same time, according to the development requirements of domestic and foreign industries,we have formulated and developed a set of specifications for liquid beverage packaging equipment,which has been implemented.We are always committed to providing customers with the best equipment and services. At present,the equipment is exported to domestic and overseas markets more than 30 regions and countries. Welcome more friends come to negotiate and consult.

Turnkey Solution Service

High-quality equipment, perfect service, abundant operation of the whole plant, strong turnkey service capability of the

wholeplant, HZM helps customers achieve a high-efficiency operation of equipment.

wholeplant, HZM helps customers achieve a high-efficiency operation of equipment.

Installation / Debugging / Training

After the customers received the equipment, HZM will send experienced engineers to the customer's factory to do installation and

commission services, and provide theoretical and technical training.

commission services, and provide theoretical and technical training.

After-Sales Service

HZM meets customer requirement in the shortest time with a complete service platform and fast response mechanism.Provide 7*24 hours after-sales service, comprehensive after-sales protection, timely and effective problem solving mechanism.

Spare Parts

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

HZM Customers

After Sales Service

1. Installation

Two weeks before shipping, the seller shall communicate with the buyer about the on-site requirements for cases

unloading,installation and commissioning etc. The seller shall assist the buyer to evaluate the project site and procedure for the total process.

2.commissioning.

After all equipment arrives at user’s factory, the packed cases should be opened to check goods amount with both parties’

personnel on-site and seller technicians will guide the installation, commissioning and trial run. The equipment should achieve designed capacity in the planned time. During installation and commissioning, seller is responsible for providing relevant spare parts.

Two weeks before shipping, the seller shall communicate with the buyer about the on-site requirements for cases

unloading,installation and commissioning etc. The seller shall assist the buyer to evaluate the project site and procedure for the total process.

2.commissioning.

After all equipment arrives at user’s factory, the packed cases should be opened to check goods amount with both parties’

personnel on-site and seller technicians will guide the installation, commissioning and trial run. The equipment should achieve designed capacity in the planned time. During installation and commissioning, seller is responsible for providing relevant spare parts.

3.Quality guarantee We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract.

4. After sales

After equipment acceptance, seller provides 24months warranty for repair and supplies free parts and effective service in time. All the parts supplied have the same quality with original ones. Fastest response, quickest supply and best service is achieved due to comprehensive after sales service team and spare parts management system. Thus the equipment by the buyer is able to run without fault with biggest guarantee. Spare parts plan’ and ‘maintenance plan’ will be suggested to customers according to their actual equipment running conditions each year. We will try our best to guarantee each line of our customer run safely and stable. .

4. After sales

After equipment acceptance, seller provides 24months warranty for repair and supplies free parts and effective service in time. All the parts supplied have the same quality with original ones. Fastest response, quickest supply and best service is achieved due to comprehensive after sales service team and spare parts management system. Thus the equipment by the buyer is able to run without fault with biggest guarantee. Spare parts plan’ and ‘maintenance plan’ will be suggested to customers according to their actual equipment running conditions each year. We will try our best to guarantee each line of our customer run safely and stable. .

FAQ

Q1:Are you a trading company or a manufacturer?

A1:We are an old filling machine company, specializeing in filling machine, berverage line,water treatment, shrinking label

machine and Bottle blowing machine. Now we are one of leading filling machine manufacturer in china.

Q2:What's your guarantee or the warranty of the quality if we buy machines?

A2:We provide quality machines with top brand.components and qualified material. Our warrantee time is 2 years after installation

and commissioning, within 2 years the machines get quality problem, we will take full responsibility and provide services.

Q3:When can I get machine after I paid?

A3:We will deliver filling machines on time as the date we agreed both side.

Q4:How can I install my drinking water filling machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians

how to run the drinking water filling machines. Also supporting online installation.

Q5:What's the delivery time?

A5:50 days after the T/T deposit or L/C for unit machine.60-90days for project line.

A1:We are an old filling machine company, specializeing in filling machine, berverage line,water treatment, shrinking label

machine and Bottle blowing machine. Now we are one of leading filling machine manufacturer in china.

Q2:What's your guarantee or the warranty of the quality if we buy machines?

A2:We provide quality machines with top brand.components and qualified material. Our warrantee time is 2 years after installation

and commissioning, within 2 years the machines get quality problem, we will take full responsibility and provide services.

Q3:When can I get machine after I paid?

A3:We will deliver filling machines on time as the date we agreed both side.

Q4:How can I install my drinking water filling machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians

how to run the drinking water filling machines. Also supporting online installation.

Q5:What's the delivery time?

A5:50 days after the T/T deposit or L/C for unit machine.60-90days for project line.

If you want to know more message , contact us with out hesitate ! Inquiry us now !

Contact Information

T e l : +86 183 2682 1424

Whatsapp : +86 183 2682 1424

E-mail : rorke@hzmmachinery.com

2475327205@qq.com

E-mail : rorke@hzmmachinery.com

2475327205@qq.com

Hot Searches