- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V,50Hz

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

18*8*9 m

-

Weight:

-

175 kg

-

Features:

-

Easy Operation

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Advantage:

-

Less energy consumtion

-

Type:

-

Full-automatic

-

Fuel:

-

Coal,heavy oil,gas etc.

-

Price:

-

Competitive

-

Working condition:

-

Stable and safe

-

Raw material:

-

Natural Gypsum Ore

-

Technology:

-

Rotary Calciner

-

Experience:

-

Over 20 years

-

Structure:

-

Simple

Quick Details

-

Application:

-

gypsum power production

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAFU

-

Voltage:

-

380V,50Hz

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

18*8*9 m

-

Weight:

-

175 kg

-

Features:

-

Easy Operation

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Advantage:

-

Less energy consumtion

-

Type:

-

Full-automatic

-

Fuel:

-

Coal,heavy oil,gas etc.

-

Price:

-

Competitive

-

Working condition:

-

Stable and safe

-

Raw material:

-

Natural Gypsum Ore

-

Technology:

-

Rotary Calciner

-

Experience:

-

Over 20 years

-

Structure:

-

Simple

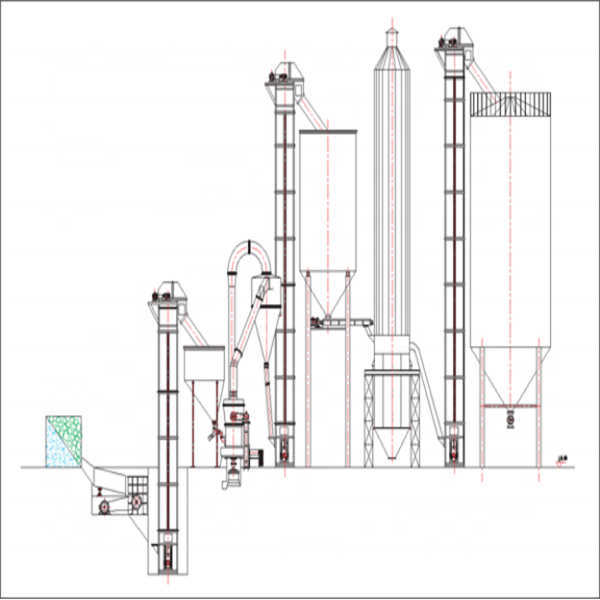

2023 Full-automation Easy operation gypsum plaster plant with ISO,CE

With the development of gypsum industry, there is a large demand for quantity and high quality of gypsum powder.Therefore, high level of gypsum powder production technology is required. In the process of gypsum powder production,drying and dewatering is the key link, which is also the most difficult one to control. In order to solve this problem,we develop a new type of drying and dewatering equipment--ebullience calciner,which is produced based on exploring of the gypsum production filed.

The working principle of ebullience calciner

Main working principle of the ebullience calciner drying system: the main part of the ebullience calciner is formed by small-diameter cooling coil pipes.The heat transfer oil is piped into coil pipe and releases heat into the internal of furnace after exchanging heat. Roots blower which can blow the cold wind into the furnace by air distribution plate is equipped at the bottom part of the ebullience calciner,by blowing let the powder in furnace boiling.

Under certain temperature,the powder which has been dried and without crystallization water becomes light, so it can flow to the outlet automatically.The quality of the gypsum powder produced in this way is stable and the content of crystallization water is large,so it is easy to control the time of solidification.

In addition, the dry electrostatic precipitator was equipped to this machine; the efficiency of dustremoval can reach more than 95% after the dust removal, eliminating the dust pollution.

If you are interested in our gypsum powder production line and want to get more information about it, pls feel free to contact me by sending an inquiry or chating with me online, I will try my best to service for you. Thanks for your clicking.