- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

Depends on Model's size

-

Weight:

-

4800 KG

-

Warranty:

-

12 months

-

Product name:

-

GTYZ Circular Vibrating Screen

-

Usage:

-

Mining Separator

-

Certificate:

-

ISO9001

-

Material:

-

Stainless Steel

-

Capacity:

-

10-245t/h

-

Motor model:

-

G160M-6

-

Installation:

-

Technical Guidance

-

After sale service:

-

Life-long Service

-

Keyword:

-

vibrating screen

-

Local Service Location:

-

Viet Nam, Indonesia

-

Certification:

-

ISO9001:2008

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guote

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

Depends on Model's size

-

Weight:

-

4800 KG

-

Warranty:

-

12 months

-

Product name:

-

GTYZ Circular Vibrating Screen

-

Usage:

-

Mining Separator

-

Certificate:

-

ISO9001

-

Material:

-

Stainless Steel

-

Capacity:

-

10-245t/h

-

Motor model:

-

G160M-6

-

Installation:

-

Technical Guidance

-

After sale service:

-

Life-long Service

-

Keyword:

-

vibrating screen

-

Local Service Location:

-

Viet Nam, Indonesia

-

Certification:

-

ISO9001:2008

GTYZ-1860 sieving screen for limestone gravels,grizzly screen for gravel

Introduction

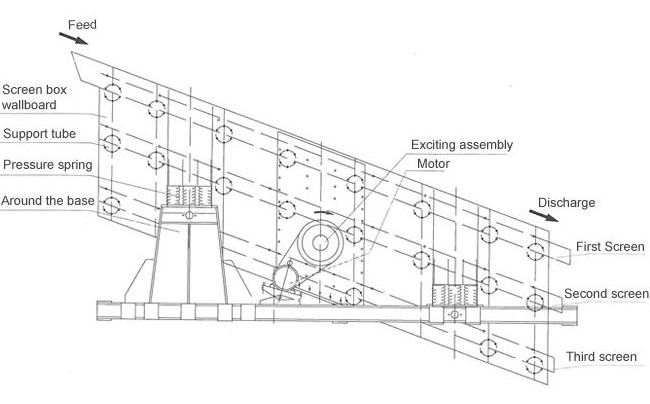

GTYZ eccentric shaft vibrating screen Vibrating screen works by means of reciprocating and rotating vibration generated by oscillator excitation.

Good quality GTYZ- circular vibrating screen for gravel and sand classifcation

Good performance GTYZ- 1848 stone crusher screen vibrating sieve for glass

- The upper rotating weight of the oscillator causes the plane rotary vibration of the screen surface, while the lower rotating weight causes the conical rotary vibration of the screen surface.

- The combined effect of the upper rotating weight and the lower rotating weight causes the complex rotary vibration of the screen surface.

- Its vibration trajectory is a complex spatial curve. The curve is projected as a circle on the horizontal plane and an ellipse on the vertical plane.

- The amplitude can be changed by adjusting the exciting force of the upper and lower rotating weights.

- By adjusting the spatial phase angle of the upper and lower weights, the curve shape of the trajectory of the screen surface can be changed and the trajectory of the material on the screen surface can be changed.

GTYZ eccentric shaft vibrating screen has simple structure, large screening capacity, low energy consumption and easy maintenance.

- It is widely used in mining, coal, electric power, metallurgy, building materials, refractory materials, etc.

- to classify large block materials and medium and small granular materials.

GTYZ Quartz circular vibrating screen I t is a kind of filter mechanical separation equipment used for slurry solid phase treatment, which consists of screen and oscillator.

- The sieve size is expressed in terms of meshes. Generally, the sieve size below 50 meshes is coarse, and the sieve size above 80 meshes is fine.

- The oscillator is an eccentric wheel, which rotates under the drive of the motor and makes the screen frame vibrate.

- Because of the vibration of the screen frame, when the slurry flows to the screen surface, the thicker solid particles stay on the screen surface and are discharged from one end along the inclined plane.

- The finer solid particles and the slurry liquid flow to the slurry pool through the screen hole together.

-

Outstanding Advantages

1. The excitation force can be randomly controlled to facilitate modular design and use.

2. The simplification of the screen structure trend is conducive to improving the manufacturing process and assembly accuracy of the equipment.

3. Use a flexible joint such as a cross-axis joint drive shaft or a rubber coupling to run smoothly.

4. Screening machine has high screening efficiency, large amount of processing, long service life and long service life.

5. The equipment maintenance is simple and convenient, and the overall operation efficiency is obvious.

Parameter

| Mode | Feeding particle size (mm) | Sieve pore size (mm) | Capacity(t/h) |

Motor model Power(kw) |

Reference weight (kg) | Double-amplitude (mm) | |

| GTYZ1230 | ≤150 | 10-80 | 75-245 | G160M-6 | 7.5 | 2800 | 6-10 |

| GTYZ1530 | 80-255 | G160M-6 | 7.5 | 3440 | |||

| GTYZ1536 | 95-310 | G160M-6 | 7.5 | 3650 | |||

| GTYZ1836 | 115-370 | G160L-6 | 11 | 5310 | |||

| GTYZ1848 | 150-490 | G160L-6 | 15 | 6410 | |||

| GTYZ2045 | ≤200 | 10-100 | 165-520 | G180L-6 | 15 | 8900 | 8-12 |

| GTYZ2060 | 170-550 | G200L1-66 | 18.5 | 1100 | |||

| GTYZ2148 | 175-570 | G225M-8 | 22 | 10700 | |||

| GTYZ2160 | 220-715 | G225M-8 | 22 | 11900 | |||

| GTYZ2460 | 250-810 | G250M-8 | 30 | 13600 | |||

| GTYZ3060 | 300-960 | G250M-8 | 30 | 16800 | |||

- 1 Packaging: Specially made wooden boxes and containers

- 2 Shipping: 5-45 days after receiving initial payment

Pre-sales Service:

- Based on customers’ request, the technicians will design drawing and final solution.

- Mostly, Welcome to visit tour factory , tickets, hotels, food and local tour are provided for every visiting customer.

-

24-hour professional customer service waiting for your consultation

- Professional laboratories and R&D technicians test your samples and customize production lines and equipment

After-sales Service:

- One or more engineers will be sent to the quarry site for installment and training.

- If any problem happen during use technicians guidance is available by internet or phone.

-

24-hour professional customer service waiting for your consultation

- Professional laboratories and R&D technicians test your samples and customize production lines and equipment