- Product Details

- {{item.text}}

Quick Details

-

Power:

-

56kw,90kw,123kw,154kw

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

max:40000x2400x4500mm

-

Year:

-

2021

-

Raw material:

-

meat flour,bone flour, corn flour and other grain's powder

-

Machine Material:

-

Staines Steel

-

Model:

-

LT65,LT70,LT85,LT90

-

Color:

-

Silver

-

Package:

-

Wooden Case

-

eletronic parts brand:

-

FU JI and LG

-

main motror brand:

-

SIEMENS

-

voltage:

-

380v/220v/customerzied

-

Application:

-

pet animal food

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LIGHT

-

Voltage:

-

220V/380V or customerzied

-

Power:

-

56kw,90kw,123kw,154kw

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

max:40000x2400x4500mm

-

Year:

-

2021

-

Raw material:

-

meat flour,bone flour, corn flour and other grain's powder

-

Machine Material:

-

Staines Steel

-

Model:

-

LT65,LT70,LT85,LT90

-

Color:

-

Silver

-

Package:

-

Wooden Case

-

eletronic parts brand:

-

FU JI and LG

-

main motror brand:

-

SIEMENS

-

voltage:

-

380v/220v/customerzied

-

Application:

-

pet animal food

-

After Warranty Service:

-

Video technical support

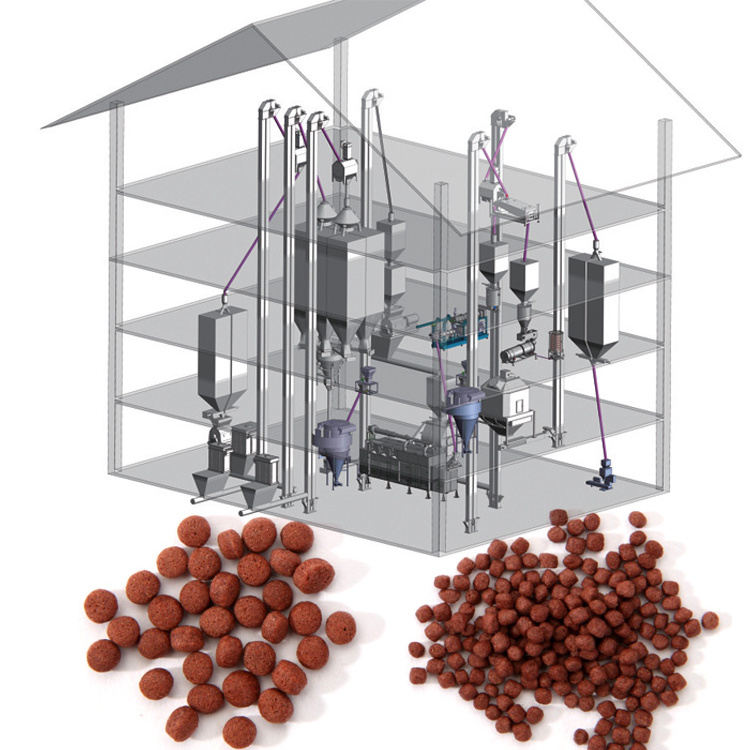

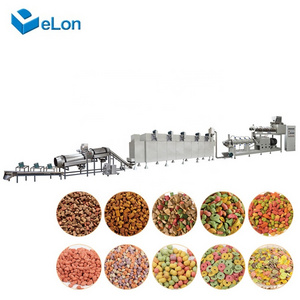

Product Application

With the increasing variety of pet, people require more and more different pet foods. In order to meet various feeding demands, Our company developed this line, easy operation, friendly human-machine interface, accurate control to ensure the food can be processed under stable temperature, pressure, humidity and other circumstance.

This line mainly use the meat meal, fish meal, bone powder, corn powder, soya meal and other grains' powder as main materials to produce the innovative shapes, high nutritional and savory taste pet food for dog, cat, fox, bird etc.

|

Model

|

Main Motor Power

|

Output

|

Size

|

|

LT-132

|

132/160 kw

|

4-5T/h

|

46X3X4 m

|

|

LT-115

|

132/160 kw

|

2-3T/h

|

42X3X4 m

|

|

LT-90

|

75/90 kw

|

1-1.2T/h

|

40X2.4X4 m

|

|

FT-95

|

90/110 kw

|

1-1.5T/h

|

40X3X4 m

|

|

FT-75

|

55/75 kw

|

400-500kg/h

|

24X2X2.8 m

|

|

LT-85

|

55/75 kw

|

400-600kg/h

|

30X2.5X4 m

|

|

LT-70

|

37 kw

|

200-250kg/h

|

25X1.5X2.2 m

|

|

LT-65

|

22 kw

|

120-150kg/h

|

22.5X1.2X2.2 m

|

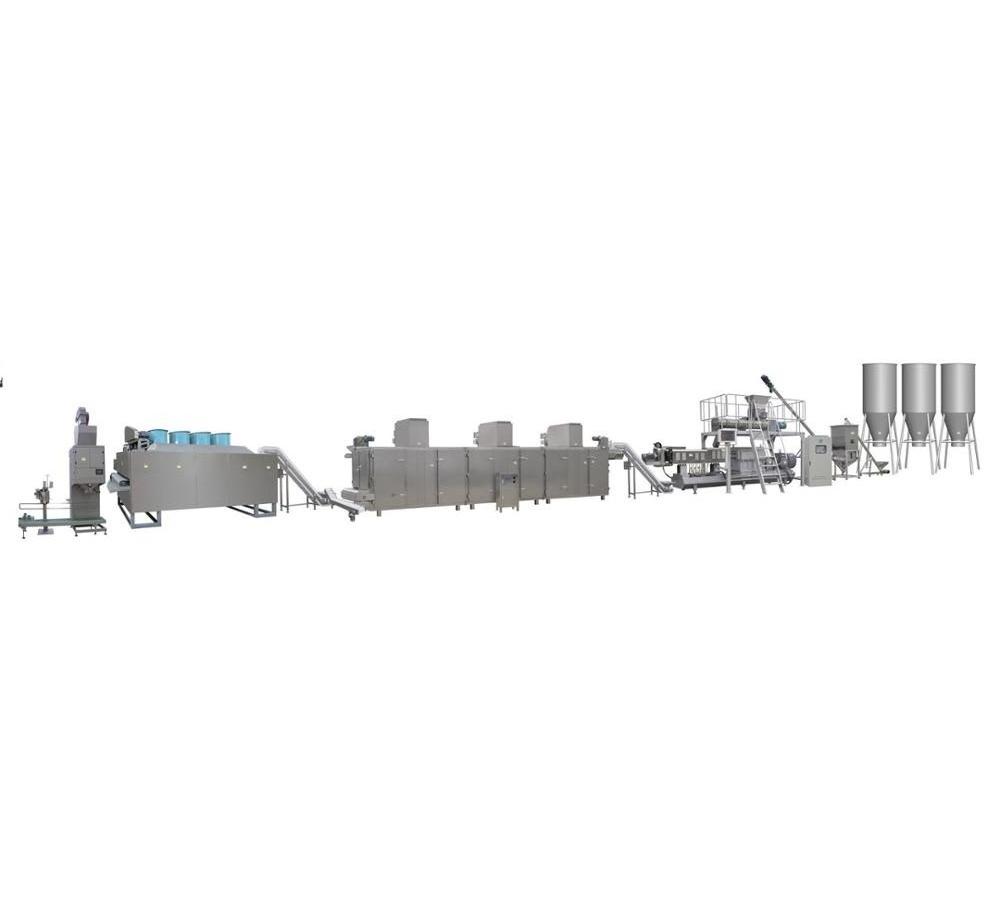

Automatic Batching Machine

The features of this series concrete batching machine are reasonable layout, compact structure, easy operation, precise ingredients, reliable control, etc.

Pulverizer

Main features:

Mainly used in feed plant for feed grinding also can used in soyabean, and other soft mineral grinding.

Double Screw Extruder

Machine part:

Siemens ChinaMain Motor, Japam FUJI, Korean LG Electric Parts, Taiwan Delta Inveter

Function:

Extruding the mixture into different shapes of fish feed based on different parameters

(INCLUDING: storage bin, Double Axis Conditioner for pre cooked, Support Platform, Center Cutting System 2 Free Moulds)

Dryer

Drying time:

15 to 60 min; Time can be change according to user's requirement.

Function:

This kind of oven has a wide range of application. It can dry all shapes of puffing food, including strip, lump, granular materials etc, as well as other types of materials.

Spray-spraying machine

Advantage:

Rotary roller adopts complete molding without dead angle.

Function:

To make food overturning inside the coating drum,

to catch more oil and flavors. The materials, flavoring and oil are stirred and mixed in the roller until well distributed.

Main features:

Mainly applicable to a varitey of granular material cooling.

Adopted countercurrent cooling principle, full cooling and unformity.

A new cooling warehouse, pneumatic flexible nesting, greatly reducing material damage.

Smooth and reliable work, down without leakage.

Packing Machine

Main features:

Suitable to package fragile materials demanding high accuracy.

Complete the whole procedure of feeding, measuring, bagging, date printing, charging(exhausting), finished product outputting automatically.

High accuracy, high efficiency without crashing the material.

Details of cooperation:

(1) Payment terms: 30% of the amount should be paid as deposit, and the balance 70% should be paid before shipment by T/T.

(2) Installation: We will send engineers to the buyer's factory for a 10-day period installation and training to the operators. All the related expenses will be on the buyer's account ( Ticket, food and accommodation ). And the installation fees is USD 80 per day.

(3) After the receipt the advanced payment, we will provide allocation chart at the buyer's request. When effect the shipment, we'll provide operation manual, etc. in English.

(4) Guarantee :We provide some spare parts for free and provide one years guarantee.