- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2100W

-

Dimension(L*W*H):

-

720*400*100mm

-

Weight (KG):

-

90 kg

-

Product name:

-

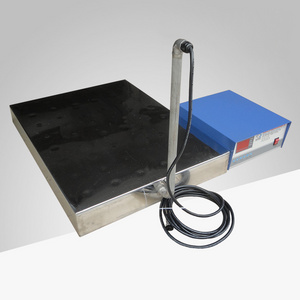

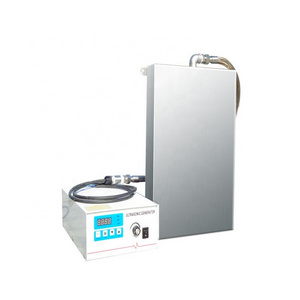

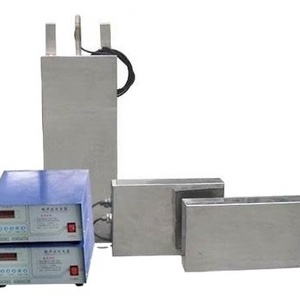

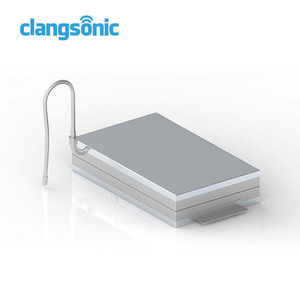

Immersible Ultrasonic Transdcuer

-

Application:

-

Hardware Industry

-

Ultrasonic Power:

-

2100W

-

Ultrasonic Frequency:

-

28/40KHz Optional

-

Tank Material:

-

SUS304/SUS316

-

Internal Tank Size:

-

720*400*100mm

-

Keyword:

-

Immmersion Ultrasonic Transducer

-

Usage:

-

Ultrasound Underwater Vibration Cleaning Device

-

Feature:

-

Critical Cleaning

-

Technology:

-

Ultrasonic Degassing

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GW SONIC

-

Power:

-

2100W

-

Dimension(L*W*H):

-

720*400*100mm

-

Weight (KG):

-

90 kg

-

Product name:

-

Immersible Ultrasonic Transdcuer

-

Application:

-

Hardware Industry

-

Ultrasonic Power:

-

2100W

-

Ultrasonic Frequency:

-

28/40KHz Optional

-

Tank Material:

-

SUS304/SUS316

-

Internal Tank Size:

-

720*400*100mm

-

Keyword:

-

Immmersion Ultrasonic Transducer

-

Usage:

-

Ultrasound Underwater Vibration Cleaning Device

-

Feature:

-

Critical Cleaning

-

Technology:

-

Ultrasonic Degassing

Product Description

|

Model No

|

Ultrasonic Power

|

Ultrasonic Frequency

|

size(L*W*H)mm

|

|

GP-1006

|

300W

|

28/40khz

|

280*220*100

|

|

GP-1012

|

600W

|

28/40khz

|

360*280*100

|

|

GP-1018

|

900W

|

28/40khz

|

420*320*100

|

|

GP-1024

|

1200W

|

28/40khz

|

510*380*100

|

|

GP-1030

|

1500W

|

28/40khz

|

510*470*100

|

|

GP-1036

|

1800W

|

28/40khz

|

650*400*100

|

|

GP-1042

|

2100W

|

28/40khz

|

720*400*100

|

|

GP-1048

|

2400W

|

28/40khz

|

800*400*100

|

|

|

|

|

|

Submersible Ultrasonic Transducers Introduction

burnt-on carbon, and 40 kHz frequency for general parts cleaning including precision machined components, in an agitated immersion

parts washeror stationary metal-sided tanks. Immersibles are not typically added to polypropylene, PVC, PVDF or other

plastic-based tanks as the plastic absorbs the ultrasonic energy thereby reducing the cavitation energy delivered to the part

surface.

Common application:

1. Drop in ultrasonics to existing manufacturing cleaning process lines, such as aqueous cleaning lines, passivation, plating lines, or other part finishingprocesses which require microscopic surface...

2. The heavy-duty design of the stainless-steel box has completely sealed components, which allows for precision ultrasonic cleaning in conditions normally too harsh for such precision electronics.

3. Valve bodies and manifolds with small internals not accessible for cleaning by forced spray or mechanical removal.

4. Medical devicestainless steel parts cleaning.

1. Drop in ultrasonics to existing manufacturing cleaning process lines, such as aqueous cleaning lines, passivation, plating lines, or other part finishingprocesses which require microscopic surface...

2. The heavy-duty design of the stainless-steel box has completely sealed components, which allows for precision ultrasonic cleaning in conditions normally too harsh for such precision electronics.

3. Valve bodies and manifolds with small internals not accessible for cleaning by forced spray or mechanical removal.

4. Medical devicestainless steel parts cleaning.

Specification

Hot Searches