- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BS-500

-

Power:

-

128KW, 128KW

-

Product name:

-

Car battery recycling machine

-

Application:

-

Recycling Machine

-

Model:

-

BS-500

-

Color:

-

Customer's Requirement

-

Voltage:

-

380V/50Hz/3 Phase

-

Final product:

-

Graphite powder

Quick Details

-

Production Capacity:

-

300L/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CANAMX

-

Model Number:

-

BS-500

-

Power:

-

128KW, 128KW

-

Product name:

-

Car battery recycling machine

-

Application:

-

Recycling Machine

-

Model:

-

BS-500

-

Color:

-

Customer's Requirement

-

Voltage:

-

380V/50Hz/3 Phase

-

Final product:

-

Graphite powder

Lithium Battery recycling machine:

Lithium-ion battery is the best rechargeable chemical battery in the world. It has the advantages of high working voltage, large specific energy, long cycle life, small self-discharge, no memory effect, no pollution, etc. It is widely used in mobile communication and notebook. Computers, portable tools, electric bicycles and other fields.

Lithium battery consumption is huge, and the consumption of non-renewable metal resources is quite large. Therefore, it is of great significance to recover lithium metal batteries with high economic value and high content of metals to achieve energy saving, emission reduction and sustainable development.

Cobalt, lithium, copper and plastic in used lithium batteries are valuable resources with high recycling value. Therefore, the scientific and effective treatment and disposal of waste lithium batteries not only has obvious environmental benefits, but also has good economic benefits.

Application:

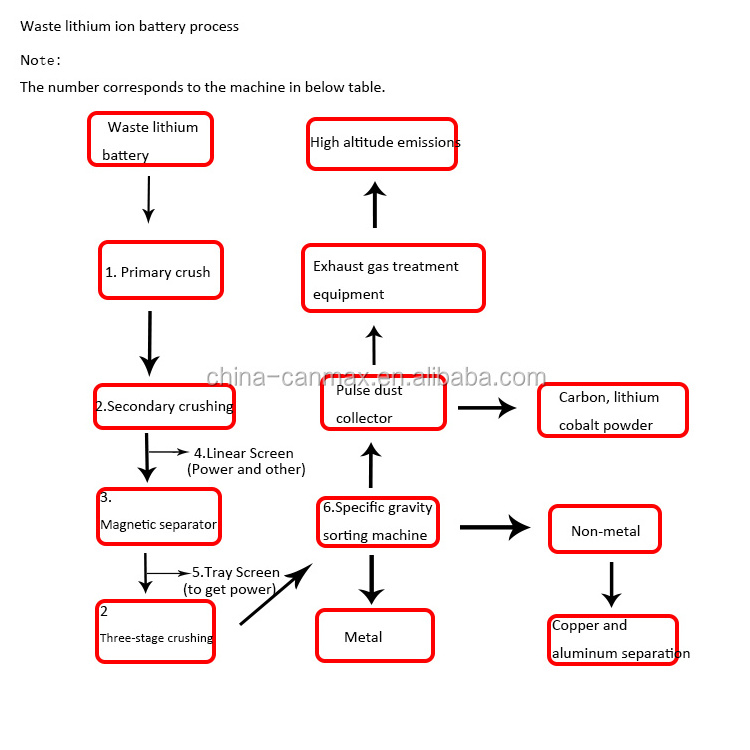

Lithium Battery Processing line:

Related Lithium battery recycling equipment :

1.Shredder: shred the lithium battery

2.Crusher: Secondary crushing and separation of shredded materials

3. Magnetic separator: separating Fe from metal

4.Linear screen :used to get powders and metal.

5.Tray screen:Used to rescreen powders and metal materials ,etc

6.Air flow sorter:Used to separate aluminum and copper.

Main Products:

| 1.Shredder | |||||

|

Model | Power(kw) | Capacity(kg/h) | Blade No.(pcs) | Blade Dia(mm) |

| BS-500 | 7.5*2 | 400-600 | 16 | 220 | |

| BS-600 | 11*2 | 600-800 | 24 | 220 | |

| BS-800 | 22*2 | 800-1000 | 32 | 220 | |

| BS-1000 | 45*2 | 1000-1300 | 40 | 220 | |

| 2.Crusher | |||||

| Model | Power(kw) | Capacity(kg/h) | Blade No.(pcs) | Roating Speed(R/MIN) | |

| FS-600 | 22 | 500-800 | 10 | 530 | |

| FS-700 | 30 | 800-1000 | 10 | 530 | |

| FS-900 | 45 | 1500-2000 | 15 | 480 | |

| FS-1200 | 75 | 2000-2500 | 20 | 410 | |

| 3.Magnetic Separation | |

| Principle:Magnetic sepraration is based on the difference in mineral magnetic properties ,and iron is selected from the mixture. | |

| 4. Linear Screen | |

| Principle: The linear screen uses vibration motor excitation as the vibration source, so that the material is thrown up on the screen and moves forward in a straight line,The material enters the feeding port of the screening machine evently from the feeder and passes through the multi-layer screen, The net produces several kinds of sieves,which are discharged from the respective outlets.(Mainlt to get a powdery substance). | |

| 5. Tray Screen | |

| Principle:The powder is Obtained from the mixture by sieving. |

| 6.Air flow sorter | |

| Principle:The Air Flow Sorter is a sorting device that separatethe mix powdery material into light and heavy parts by the principle of air suspension. | |

Cases:

Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipments strictly according to your special requirements and arrange the timely delivery.

After-sale service

(1) Installation guidance

When the machine arrives at your company, we will dispatch our technicians to your factory to guide the installation and commissioning at site.

(2) Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3) Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

Certificate: