- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380

-

Dimension(L*W*H):

-

900*600*800

-

Power (kW):

-

5

-

Weight:

-

400 KG

-

Keywords:

-

pvc

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

25:1

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYD

-

Voltage:

-

380

-

Dimension(L*W*H):

-

900*600*800

-

Power (kW):

-

5

-

Weight:

-

400 KG

-

Keywords:

-

pvc

-

Marketing Type:

-

Ordinary Product

Product Description

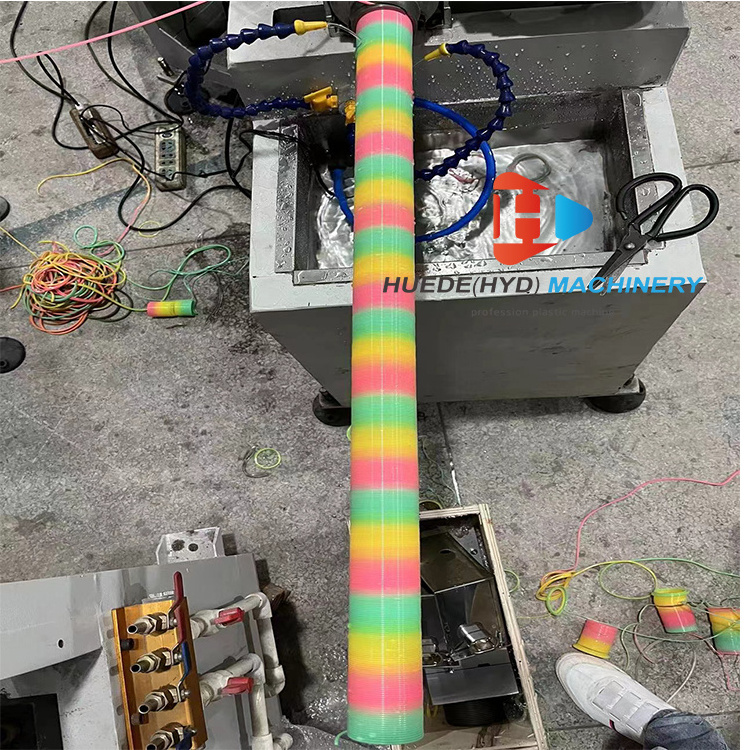

rainbow circle toy productione Line

plastic granulation line feature:

1. Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 workers are

enough to run this machine, to feed the materials and change pellet receiver.

2. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long

working life of this machine, it can save many sources in energy!

3. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

1. Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 workers are

enough to run this machine, to feed the materials and change pellet receiver.

2. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long

working life of this machine, it can save many sources in energy!

3. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

PVC Profile Extrusion Line

Details Images

Title goes here.

Consist of:

Belt conveyor(metal detector) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub- extruder → Hydraulic screen changer → Water ring cutting system →Dewatering machine → Air blow system → Storage hopper → control cabinet

Belt conveyor(metal detector) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub- extruder → Hydraulic screen changer → Water ring cutting system →Dewatering machine → Air blow system → Storage hopper → control cabinet

Customer comments

Customer&Service

Factory View

Packing & Delivery

Hot Searches