A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

hongfa

-

Application:

-

Manufacturing Plant, Construction works , AAC Block production line

-

Method:

-

Autoclaved Aerated Concrete

-

Voltage:

-

220V/380V/440V

-

Capacity:

-

50000m3 to 500,000m3 per year

-

Final product type:

-

AAC block, lightweight block

-

Raw material:

-

Cement/lime/sand

-

Advantages:

-

Environmental Friendly/light weight/fireproofing/therminal insulation

-

Usage:

-

Building Houses

-

Color:

-

Optional

-

Certification:

-

CE ISO

Quick Details

-

Weight (KG):

-

120000

-

Marketing Type:

-

hot product 2022

-

Place of Origin:

-

China

-

Brand Name:

-

hongfa

-

Application:

-

Manufacturing Plant, Construction works , AAC Block production line

-

Method:

-

Autoclaved Aerated Concrete

-

Voltage:

-

220V/380V/440V

-

Capacity:

-

50000m3 to 500,000m3 per year

-

Final product type:

-

AAC block, lightweight block

-

Raw material:

-

Cement/lime/sand

-

Advantages:

-

Environmental Friendly/light weight/fireproofing/therminal insulation

-

Usage:

-

Building Houses

-

Color:

-

Optional

-

Certification:

-

CE ISO

Detailed Images

Hongfa universal parts block machine price india aac manufacturers aac plant in china

Product Description

Hongfa universal parts block machine price india aac manufacturers aac plant in china

Hongfa AAC Block Production Line

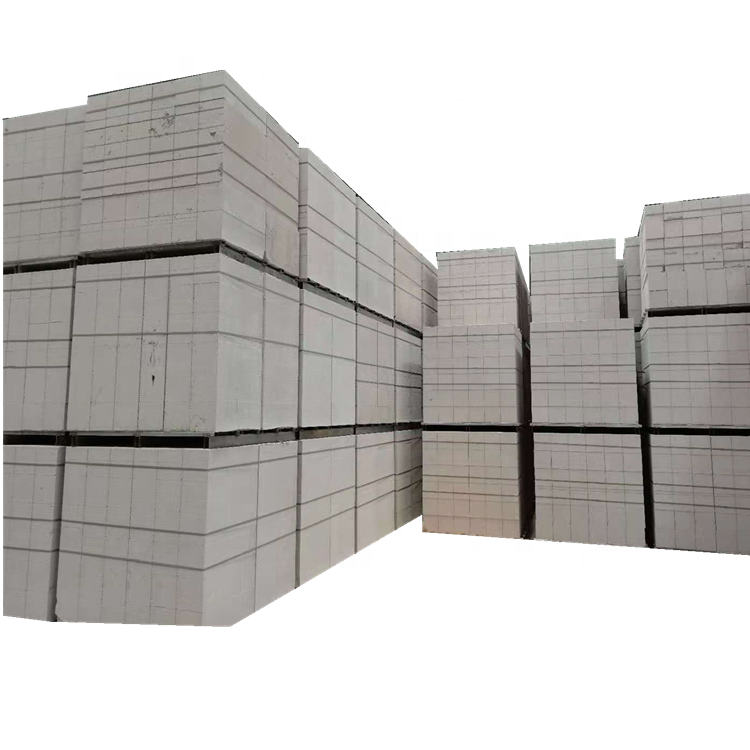

1.AAC block from Hongfa AAC block plant

Areated concrete block(light block) is the light and porous building material.

It can be made into any size of bricks and steel reinforced blocks:

such as 600x200x100mm,80x80x180mm,240x115x53mm,600x200x125mm etc. They could be used in industry building and common building. in future, AAC block is an ideal substitube for traditional clay brick.

2.Application

Autoclaved Aerated Concrete Block are widely used as external wall panel(exterior wall panel), internal wall panel, partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial

constructions, steel structure building, wharehouse, workshop, stores, hospitals, apartments, villas, schools, supermarket, etc.

Areated concrete block(light block) is the light and porous building material.

It can be made into any size of bricks and steel reinforced blocks:

such as 600x200x100mm,80x80x180mm,240x115x53mm,600x200x125mm etc. They could be used in industry building and common building. in future, AAC block is an ideal substitube for traditional clay brick.

2.Application

Autoclaved Aerated Concrete Block are widely used as external wall panel(exterior wall panel), internal wall panel, partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial

constructions, steel structure building, wharehouse, workshop, stores, hospitals, apartments, villas, schools, supermarket, etc.

Hongfa AAC production line main components

The technology that Hongfa AAC Block AAC Production Line mainly adopts the Germany Yitong process to realize the green body turning in the air, the fixed-step cutting of the green body walking, the hydraulic lifting and conveying, the bottom turning in the air, and the defoaming treatment of the steam drum.

The technology that Hongfa AAC Block AAC Production Line mainly adopts the Germany Yitong process to realize the green body turning in the air, the fixed-step cutting of the green body walking, the hydraulic lifting and conveying, the bottom turning in the air, and the defoaming treatment of the steam drum.

1.Raw material preparation for AAC plant:

-

2. Dry and wet Ball mill for lime and sand

Common model:

φ1200x4500

φ1500x5700

φ1830x7000

φ2200x8000

φ1500x5700

φ1830x7000

φ2200x8000

3.Slurry batching:

The prepared and stored raw materials to be used are metered, adjusted for temperature and concentration, and a small amount of

dosing materials are metered on-site, and then fed to the stirring equipment in turn according to the process requirements.

dosing materials are metered on-site, and then fed to the stirring equipment in turn according to the process requirements.

4. Pouring:

In this process, the materials that are put into the mixer after the previous batching process are measured and adjusted if

necessary, and the materials that meet the time, temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it constitutes the core link

of aerated production as the batching process.

necessary, and the materials that meet the time, temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it constitutes the core link

of aerated production as the batching process.

5.Cutting:

The cutting process is to divide and shape the aerated concrete body to meet the appearance size requirements.

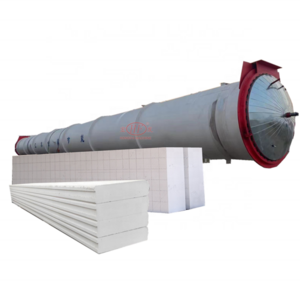

6.Autoclave curing:

High-pressure steam curing of aerated concrete aac body. (Usually above 174.5 ℃)

7. Out off Autoclave:

Including finished AAC blocks out of the autoclave, lifting, separation, inspection, packaging and cleaning and oiling of trolleys and bottom plates.

9.Waster recycle:

waste concrete cut away from green body and waste water from steam of autoclave.

Related Products

Packing&Shipping

After Sales Service

Pre-sale service support:

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order.

During-sale service support:

Assist clients to finish the factory visit planning. Before delivery equipment to customers, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit.

After-sale service support:

Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts

thoughout the year, and the maintenance technicians are always ready to provide technical help.

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order.

During-sale service support:

Assist clients to finish the factory visit planning. Before delivery equipment to customers, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit.

After-sale service support:

Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts

thoughout the year, and the maintenance technicians are always ready to provide technical help.

Company Introduction

About Hongfa Machinery Group

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic

Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic

Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

FAQ

1. What is your payment terms?

T/T 30% as deposit, 70% balance payment before delivery. Or 100% L/C at sight.

2. What’s your delivery time?

20-28 days after receiving your deposit and mould comfirmation.

3. How about quality control in your factory?

We strictly operate full QC process during production, and each machine will be tested before delivery.

4. What’s your after sales guarantee?

All our machines are guaranteed for 1 year after-sales service,lifelong maintenance.

T/T 30% as deposit, 70% balance payment before delivery. Or 100% L/C at sight.

2. What’s your delivery time?

20-28 days after receiving your deposit and mould comfirmation.

3. How about quality control in your factory?

We strictly operate full QC process during production, and each machine will be tested before delivery.

4. What’s your after sales guarantee?

All our machines are guaranteed for 1 year after-sales service,lifelong maintenance.

Contact us

Hot Searches