There are coolant nozzles on each grinding wheel and an independent cooling water tank at one end of the equipment.

- Product Details

- {{item.text}}

Quick Details

-

Wheel Size(mm):

-

200

-

Surface Roughness(μm):

-

0.01 μm

-

Table Size(mm):

-

500*250

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADJAY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1750*1350*1960

-

Weight (KG):

-

1050

-

Type:

-

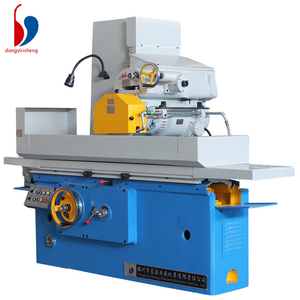

Surface Grinding Machine

-

Processing Object:

-

Metal, Ceramics and So on

-

Abrasives:

-

Grinding Wheel

-

Controlling Mode:

-

Manual

-

Automatic Grade:

-

Manual

-

Cylindrical Grinder Type:

-

Surface Grinding Machine

Quick Details

-

Grinding Length(mm):

-

520

-

Table Travel (X) (mm):

-

250

-

Table Travel (Y) (mm):

-

520

-

Wheel Size(mm):

-

200

-

Surface Roughness(μm):

-

0.01 μm

-

Table Size(mm):

-

500*250

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WADJAY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1750*1350*1960

-

Weight (KG):

-

1050

-

Type:

-

Surface Grinding Machine

-

Processing Object:

-

Metal, Ceramics and So on

-

Abrasives:

-

Grinding Wheel

-

Controlling Mode:

-

Manual

-

Automatic Grade:

-

Manual

-

Cylindrical Grinder Type:

-

Surface Grinding Machine

Product Description

AHD Left And Right Hydraulic, Front And Rear Automatic, Up And Down PLC Servo Control

★ Guide way is coated with Turcite and precision hand scraped,move smoothly and keep the accuracy long life.

★ Well-designed control panel with two-way rotate structure,make the operator getting suitable operating position very easy,improve work efficiency.

★ The grinder is standard equipped with auto down feed AC servo motor,and controlled by PLC and HMI,to realize auto grinding,then to realize auto grinding.

★ For the control panel is equiped with HMI, by whcih the operator can easy operating on the machine to realizeauto working

★ Well-designed control panel with two-way rotate structure,make the operator getting suitable operating position very easy,improve work efficiency.

★ The grinder is standard equipped with auto down feed AC servo motor,and controlled by PLC and HMI,to realize auto grinding,then to realize auto grinding.

★ For the control panel is equiped with HMI, by whcih the operator can easy operating on the machine to realizeauto working

This grinding machine mainly uses the grinding wheel to grind various materials such as steel, cast iron and non-ferrous metals. According to the material and shape of the workpiece, different clamping and positioning methods can be used. For general planes, electromagnetic chucks can be used or directly fastened to the worktable for grinding; planes, right angled surfaces, arbitrary angles, cylindrical end faces and other special shapes can be ground on fixtures or multi functional powerful electromagnetic chucks .

Specification

|

Technical Parameters

技术规格

|

Unit

单位

|

SG2550AHD

|

|

Max. workpiece to be Ground(L×W×H)

磨削工件最大尺寸(长×宽×高) |

mm

|

520×250×240

|

|

Max.Grinding Length

工作台纵向移动量 |

mm

|

520

|

|

Max.Grinding width

工作台横向移动量 |

mm

|

250

|

|

Distance from table surface to spindle center

砂轮轴中心线至工作台面距离 |

mm

|

450

|

|

Slide way 工作台滑道

|

|

One flat rail one Vrail 一平一V

|

|

Maximum work load

工作台最大承受量 |

kg

|

200

|

|

Table size(L×W)

工作台台面尺寸(长×宽) |

mm

|

520×250

|

|

Number of T-slot

工作台T型槽 |

mm×n

|

14×1

|

|

Speed of working table

工作台速度

|

m/min

|

18

|

|

Cross feed on handwheel

前后手轮进刀量 |

mm

|

0.02/Graduation 4/revolution

0.02/格 4/圈 |

|

Vertical feed on handwheel

上下MPG进刀量 |

mm

|

0.001/0.01/0.1/Graduation 0.1/1/10/revolution 0.001/0.01/0.1/格 0.1/1/10/圈

|

|

Wheel size(dia×width×bore)

砂轮尺寸(外径×宽×内径) |

mm

|

Ф200×20×Ф31.75

|

|

Spindle speeds

主轴转速(50HZ) |

rpm

|

2800

|

|

The total power of electric motor

电机总功率 |

kw

|

4

|

|

Spindle motor

主轴电机功率 |

kw

|

1.5

|

|

The machined surface of the base of parallelism 加工表面对基面的平行度

|

mm

|

0.003

|

|

Surface roughness

表面粗糙度

|

μm

|

Ra0.32

|

|

Vertical feeding svevo motor

磨头垂直进给伺服电机 |

kw

|

0.75

|

|

Cross feed motor of table

工作台前后进给电机

|

kw

|

0.06

|

|

Minimum of numerical

油箱容量

|

L/min

|

60

|

|

Coolant pump

冷却泵

|

kw

|

0.04

|

|

Packing size(L×W×H)

包装箱尺寸(长×宽×高) |

mm

|

1970*1350*1980

|

|

Gross、Net

毛重、净重

|

T

|

1.2、1.1

|

Detail Images

Grinding wheel stand

The grinding wheel of the grinding wheel stand is cooled by an independent cooling system.

Intelligent control system

Wear resistance, high efficiency, simple and sensitive operation, low noise, low vibration

Self-lubrication

At one end of the grinding machine bed, there is an independent lubrication control oil tank, which continuously lubricates the guide rails of the table movement.

Hot Searches