- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

3500

-

Product name:

-

Folding Machine

-

Machine Type:

-

Plate Folding Machine

-

Name:

-

Automatic Folding Machine

-

Application:

-

Plate Folder Machine

-

After-sales Service Provided:

-

Engineers

-

Type:

-

Metal Folder

-

Usage:

-

Sheet Folding

-

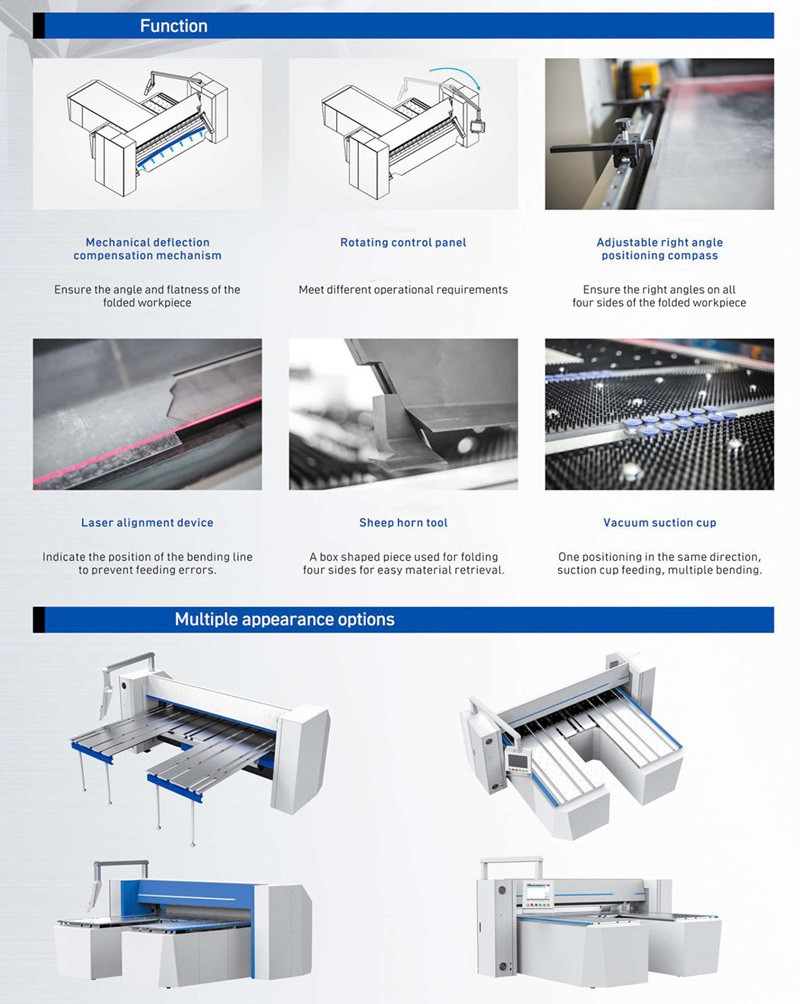

Function:

-

FOLDING BENDING

-

Raw Material:

-

Sheet

-

Keyword:

-

Steel Folding Machine

Quick Details

-

Bending Thickness(mm):

-

1.5 - 2 mm

-

Bending Length(mm):

-

2500 mm

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

3500

-

Product name:

-

Folding Machine

-

Machine Type:

-

Plate Folding Machine

-

Name:

-

Automatic Folding Machine

-

Application:

-

Plate Folder Machine

-

After-sales Service Provided:

-

Engineers

-

Type:

-

Metal Folder

-

Usage:

-

Sheet Folding

-

Function:

-

FOLDING BENDING

-

Raw Material:

-

Sheet

-

Keyword:

-

Steel Folding Machine

Product Overview

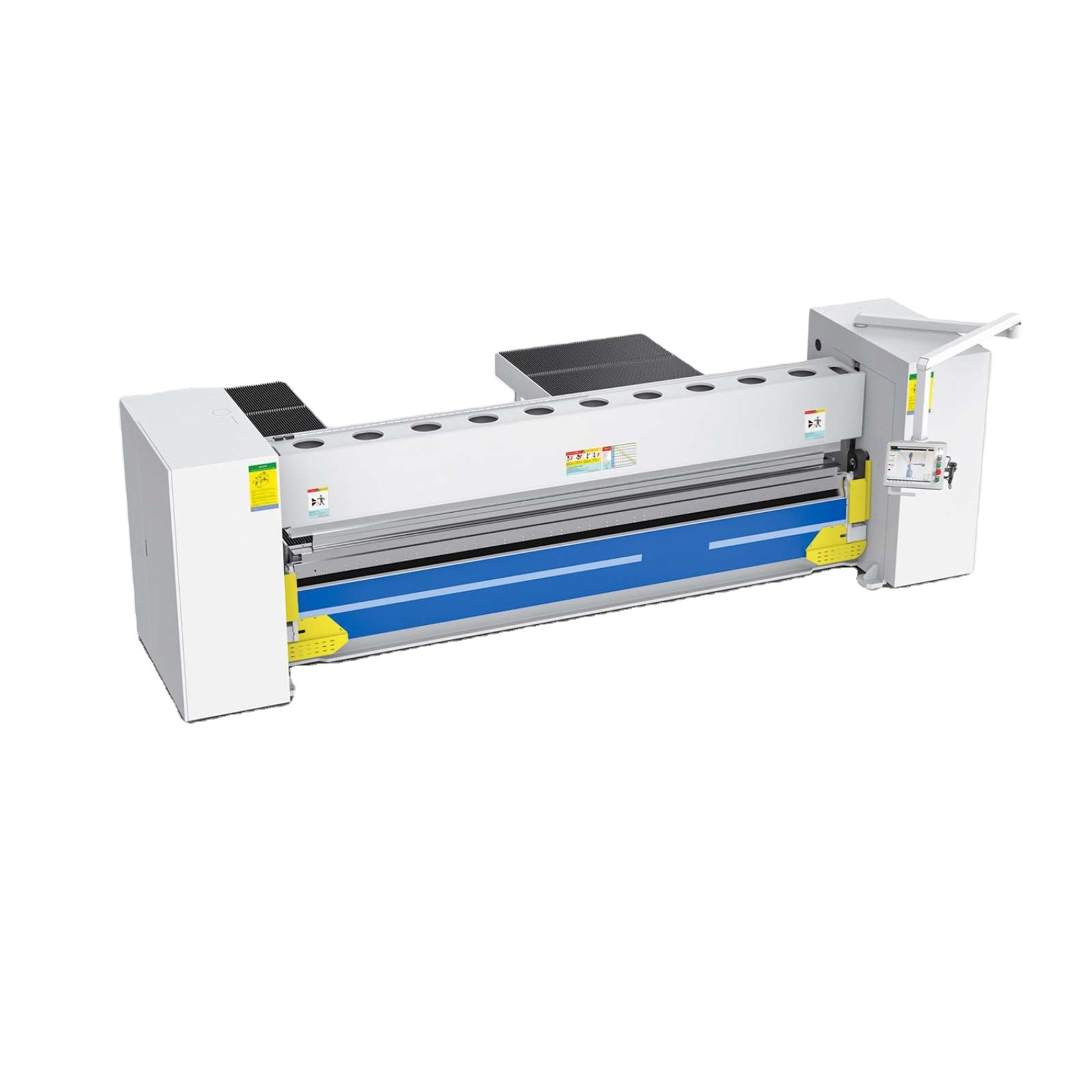

CNC sheet metal folding machine

CNC sheet metal folding machine, also known as a CNC press brake, is a piece of equipment used in metal fabrication to bend and fold sheet metal into various shapes and angles.

Programming: The operator programs the machine with the desired dimensions and angles for the bends using computer-aided design (CAD) or computer-aided manufacturing (CAM) software.

Loading: A sheet of metal is loaded onto the machine's work surface. The machine typically has clamps or other mechanisms to hold the sheet in place securely during the bending process.

Bending: The machine's electrically-powered ram moves downward to press the sheet metal against a die, which forms the desired bend. The CNC control system precisely controls the speed, force, and positioning of the ram to achieve accurate bends according to the programmed specifications.

Unloading: Once the bending process is complete, the finished piece is removed from the machine.

They are widely used in industries such as automotive, aerospace, electronics, and construction for producing various components and parts made from sheet metal.

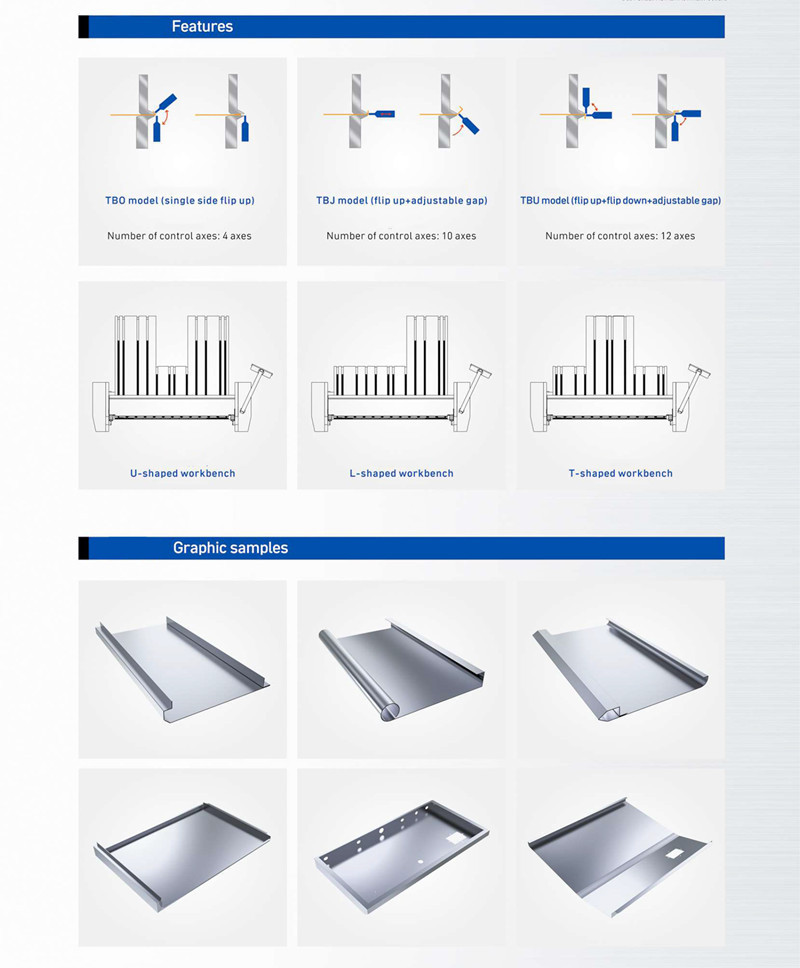

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Item

|

Unit

|

LC-TBO25

|

LC-TBO32

|

LC-TBO41

|

LC-TBJ25

|

LC-TBJ32

|

LC-TBJ41

|

LC-TBU25

|

LC-TBU32

|

|

Bending thickness(carbon steel)

|

mm

|

2.0

|

2.0

|

2.0

|

2.0

|

2.0

|

2.0

|

2.0

|

2.0

|

|

Bending thickness(stainless steel)

|

mm

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

1.5

|

|

Bending angle range

|

*

|

45-180

|

45-180

|

45-180

|

45-180

|

45-180

|

45-180

|

-45-+45

|

-45-+45

|

|

Min,bending length

|

mm

|

2500

|

3200

|

4100

|

2500

|

3200

|

4100

|

2500

|

3200

|

|

Rear positioning length

|

mm

|

2500

|

3200

|

4100

|

2500

|

3200

|

4100

|

2500

|

3200

|

|

Open height

|

mm

|

380

|

380

|

380

|

380

|

380

|

380

|

380

|

380

|

|

Bending tool height

|

mm

|

125

|

125

|

125

|

125

|

125

|

125

|

125

|

125

|

|

Control the number of axes

|

mm

|

4

|

4

|

6

|

10

|

10

|

10

|

12

|

12

|

|

Pressing speed

|

mm/s

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

|

Bending speed

|

./s

|

100

|

100

|

100

|

100

|

100

|

100

|

100

|

100

|

|

Motor energy consumption

|

kw

|

3.5

|

5.5

|

6.5

|

6.5

|

6.5

|

7.5

|

7.0

|

7.0

|

|

Dimensions

|

mm

|

3.1*3.7*1.65

|

3.8*4.5*1.9

|

5.3*5.7*2.15

|

3.1*3.7*1.65

|

3.8*4.5*1.9

|

5.3*5.7*2.15

|

3.1*3.7*1.65

|

3.8*4.5*1.9

|

|

Weight

|

kg

|

3500

|

4500

|

7500

|

4000

|

5000

|

8000

|

7000

|

9000

|

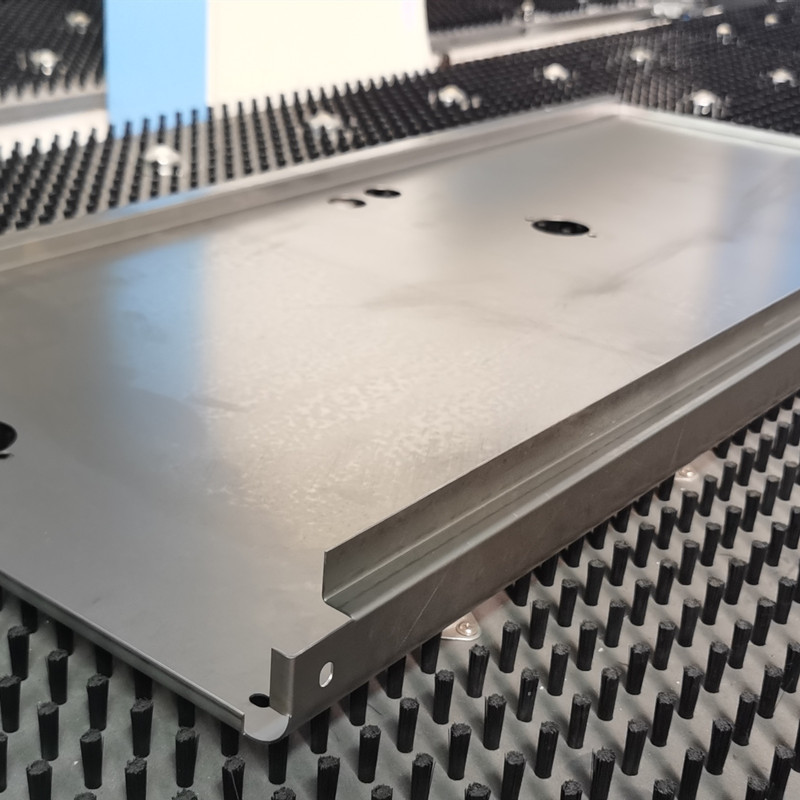

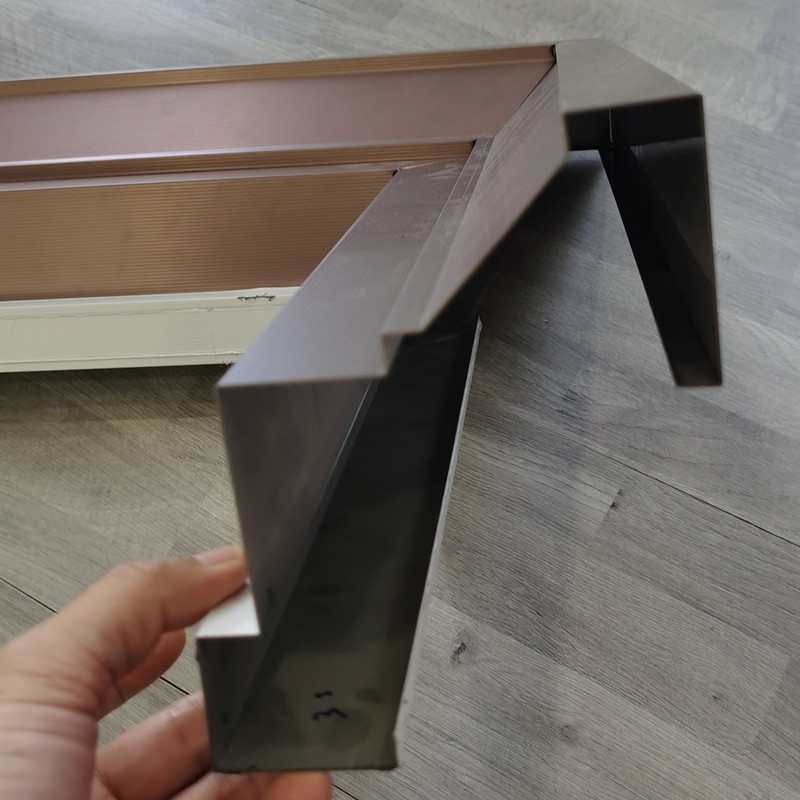

PRODUCT CONFIGURATION

Sample

Sample

Sample

SALES AND SERVICE NETWORK

Hot Searches