- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

500 KG

-

Product name:

-

Sluice Box For Gold Mining

-

Color:

-

Customized Making

-

Function:

-

separation\sorting

-

Installation:

-

Technical Guidance

-

Quality:

-

High Reputation

-

Feature:

-

High Recovery Rate Easy

-

Certification:

-

ISO CE

-

Recovery rate:

-

95-98%

-

Advantage:

-

Professional

-

Price:

-

Negotiable

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380V/220V or customized

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

500 KG

-

Product name:

-

Sluice Box For Gold Mining

-

Color:

-

Customized Making

-

Function:

-

separation\sorting

-

Installation:

-

Technical Guidance

-

Quality:

-

High Reputation

-

Feature:

-

High Recovery Rate Easy

-

Certification:

-

ISO CE

-

Recovery rate:

-

95-98%

-

Advantage:

-

Professional

-

Price:

-

Negotiable

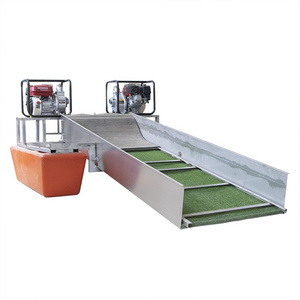

Product Description

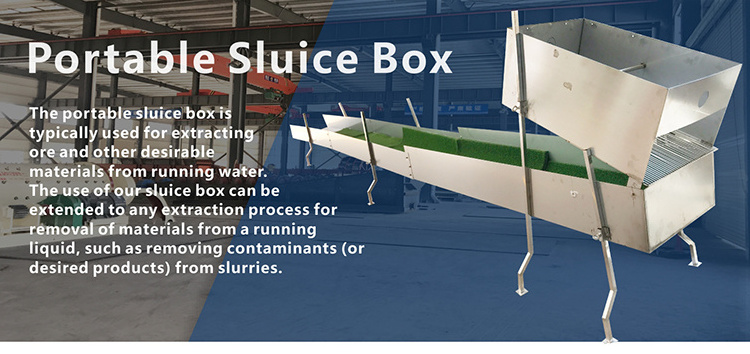

Why choose our portable sluice box

Nowadays, despite lighter options for the choice of materials used in the construction of sluice boxes, even modern sluice boxes are difficult to transport and store, particularly due to their size. A typical sluice box may be between four and eight feet in length and between one and two feet in width, thus making transportation of a sluice box, particularly to an outdoor water source, such as a stream or river, relatively difficult.

Thus, Our JXSC Mining Machinery has invented a modular portable sluice box to solve the aforementioned problems.

Our JXSC modern sluice boxes are made with materials that are far lighter and more durable than the original sluice boxes used during the Gold Rush. Also, our modular & smaller size designed structure make it more portable so you can deploy it to almost any place for your gold mining.

JXSC’s sluice boxes are typically made of sheet aluminum or composite plastic materials. This results in lighter and more portable units that are considerably more efficient at gathering even the finest of gold dust.

Working Principle

Early sluice boxes, such as those used during the Gold Rush, consisted of a simple wooden trough lined with raised obstructions placed at a 90° angle to the flow of the water.

These obstructions are referred to as “riffles”. When all of the gravel-gold mixtures was run through the sluice box, the water would be shut off, and the riffles were removed. The heavy materials, which contained the gold, would then be gathered. This extracted material is referred to as the “concentrate”. Several tons of gold-bearing gravel could be processed through the sluice box in this manner.

In use, the gold-bearing gravel, for example, is dumped into an upper end of the sluice, and the flow of water washes the material down the length of the trough defined by the box. The lighter pieces of gravel are carried in suspension down the entire length of the sluice box to come out as “tailings” at the lower end of the sluice box. Heavy material, such as gold, sinks quickly and is caught by the riffles. Once the riffles gather their fill of concentrate, the concentrate is then removed for extraction of the gold.

Products Display

Product Advantages

JXSC's portable sluice box is constructed from a plurality of smaller sluice box modules, thus allowing the sluice box to be easily disassembled for storage and transport, and assembled in a variety of different configurations.

Each of the sluice box modules includes a lower wall having a pair of longitudinally opposed ends and a pair of laterally opposed ends. A plurality of riffles are formed on an upper surface of the lower wall. A pair of sidewalls are respectively secured to the pair of laterally opposed ends of the lower wall and project upward therefrom.

A first end of the pair of longitudinally opposed ends of the lower wall of one of the plurality of sluice box modules may be releasably connected to a second end of the pair of longitudinally opposed ends of the lower wall of a longitudinally adjacent one of the plurality of sluice box modules. Similarly, a first sidewall of the pair of sidewalls of one of the plurality of sluice box modules may be releasably connected to a second sidewall of the pair of sidewalls of a laterally adjacent one of the plurality of sluice box modules.

Packaging & Delivery

Packaging: standard plywood packing

Container:40HQ/40GP/20GP

Container:40HQ/40GP/20GP

Packaging: standard plywood packing

Container:40HQ/40GP/20GP

Container:40HQ/40GP/20GP

Company Introduction

JXSC Mining Equipment Manufacturer is an experienced supplier of Gold Mining Equipment including gold wash plant, stone crusher machine, gravity concentration, magnetic separation, feeder equipment, mining laboratory equipment. Our Gold Wash Plant is widely used for gold mining plant among home and abroad, whole alluvial gold production line and gold mining equipment, diamond mining equipment, silica sand mining own a good name in the international market, owing to advanced design compare to top brands like MSI MINING.

Trusted mining equipment manufacturers leader in mineral processing technologies,ISO9001: 2008 and CE certified,providing high quality manufacturing,engineering support & professional mining design since establishing in China in 1985.

JXSC mine machinery factory, is specializing in manufacturing, and uniquely provides complete range of mining equipment, mining accessories for either placer or hard rock mineral types,also,processing and recovery of various metals and minerals: Precious Metals, Precious and Semi-Precious Stones, Base Metals, Ferrous and Non-Ferrous Metals, Noble Metals, Heavy Metals.

7*24 hours online consulting service, we provide you with the prophase plan, process flow design and

manufacturer equipment according to your special demand.

Send technicians to the job site guiding the installation and adjustment, training operators and finishing the check and accept together with you.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our

products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require? Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches