- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

5000*2750*2100mm

-

Year:

-

2024

-

Weight (KG):

-

12000

-

Power (kW):

-

4.5

-

Product name:

-

CNC V-Grooving Cutting Machine

-

Application:

-

Steel Sheet Grooving

-

Name:

-

Groover Machine

-

Keyword:

-

Metal Grooving Cutting

-

After-sales Service Provided:

-

Online Support

-

CNC or NOT:

-

CNC Control

-

Cutting Thickness:

-

0.4-8mm

-

Max.width of grooving:

-

1500mm*3200mm

-

Grooving thickness range:

-

0.4-8mm

-

Number of Cutter:

-

4PCS

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmapress

-

Marketing Type:

-

Hot Product 2024

-

Voltage:

-

380V/50Hz/3Phase

-

Dimension(L*W*H):

-

5000*2750*2100mm

-

Year:

-

2024

-

Weight (KG):

-

12000

-

Power (kW):

-

4.5

-

Product name:

-

CNC V-Grooving Cutting Machine

-

Application:

-

Steel Sheet Grooving

-

Name:

-

Groover Machine

-

Keyword:

-

Metal Grooving Cutting

-

After-sales Service Provided:

-

Online Support

-

CNC or NOT:

-

CNC Control

-

Cutting Thickness:

-

0.4-8mm

-

Max.width of grooving:

-

1500mm*3200mm

-

Grooving thickness range:

-

0.4-8mm

-

Number of Cutter:

-

4PCS

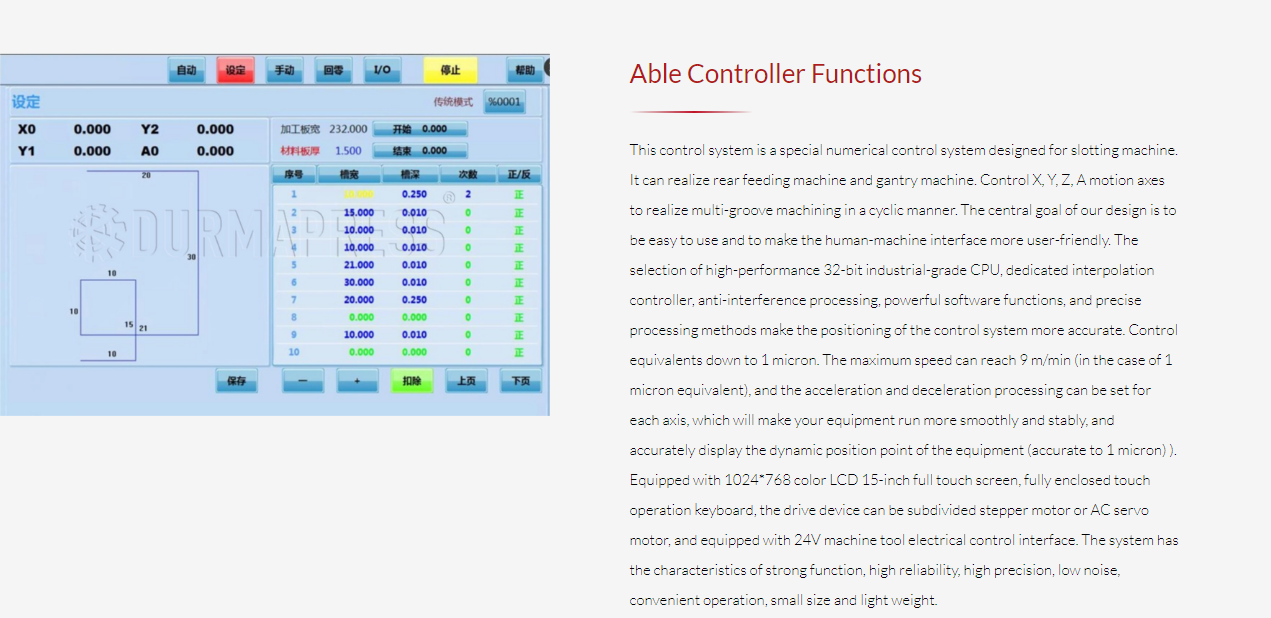

Products Description

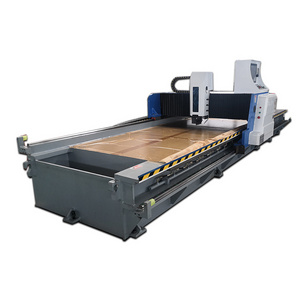

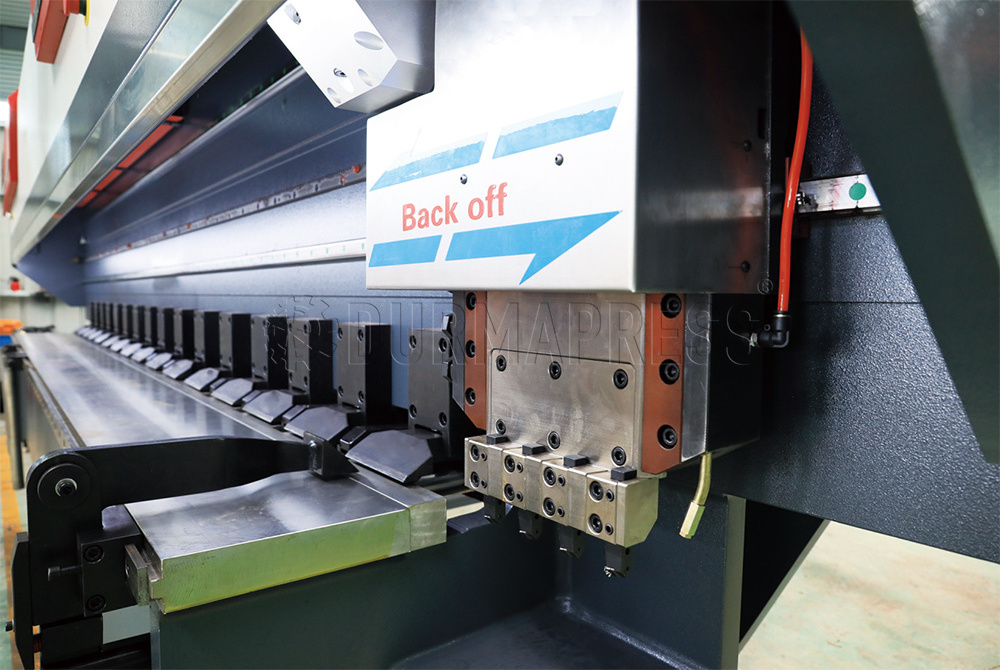

Horizontal V Groover Machine

CNC Control,Full Servo,Smooth Operation Series.

The HRK series grooving machine is an upgraded product of traditional grooving machine.

It adopts frame structure and high-strength bolt connection,with good overall rigidity and small deformation.

The worktable is made of carbon tools.After high frequency surface quenching,the hardness of the worktable reaches 55-60hc(ordinary table surface less than 30hrc),which makes the hardness of the worktable much greater than that of the stainless steel,it solves the problem of groove mark in traditional machine due to low hardness of worktable,ensures the flatness of worktable less than 0.02,thoroughly solves the problem of reducing V-groove precision due to worktable deformation,and prolongs the service life of the equipment.

The front and rear of the worktable are equipped with material supporting device to prevent the sheet metal from being scratched in the process of processing.

More Details

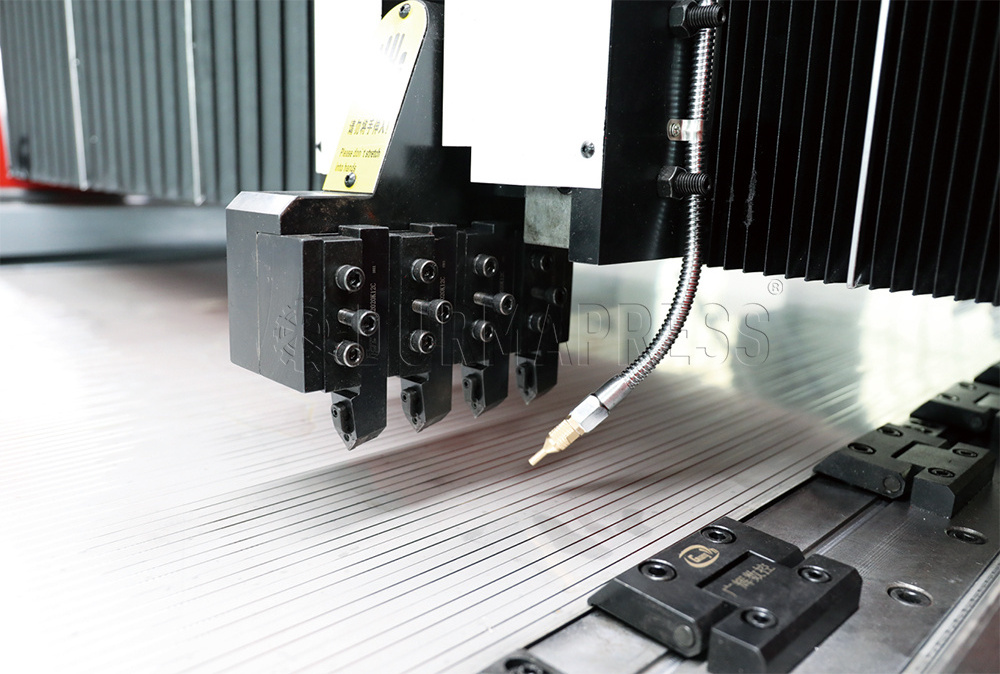

Blade

The tool holder uses a servo motor,which has a large moving torque,fast acceleration and deceleration,accurate positioning and high efficiency.

Servo Motor

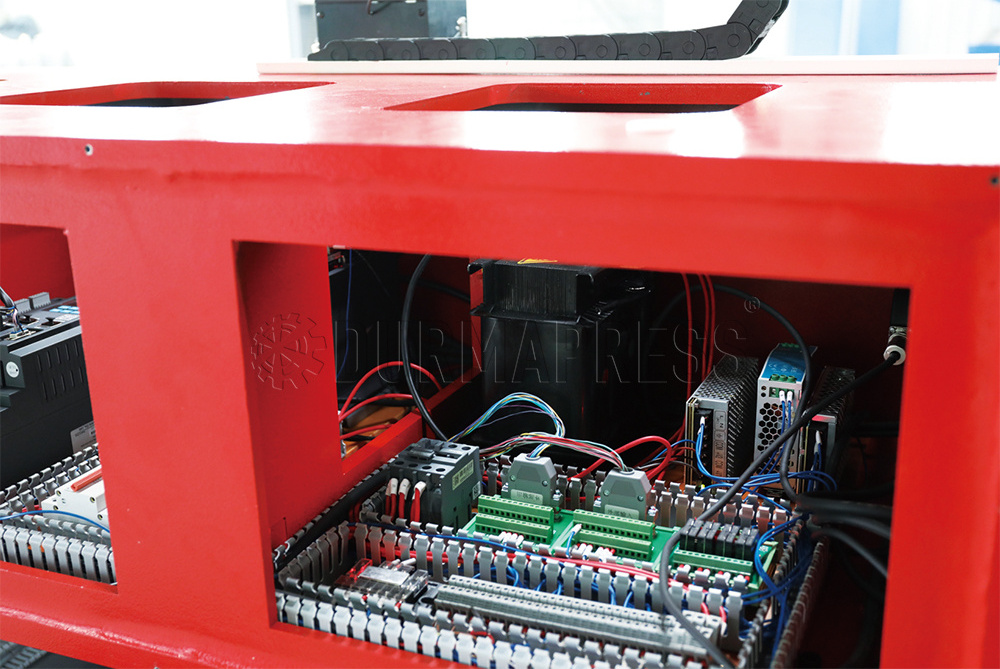

Drive system can be combined with motion control solutions provided by automation control software.

Drive system is more suitable for highly dynamic multi-axis motion drive.

Machine Body

The fuselage is clamped once in steel after welding and processed by the CNC pentahedorn machining center as a whole.The internal

stress is eliminated by the heat treatment and annealing to ensure extremely high rigidity and machining accuracy.

stress is eliminated by the heat treatment and annealing to ensure extremely high rigidity and machining accuracy.

|

Product Parameter

|

|

|

|

|

||||

|

Content

|

Required Parameter

|

Required Parameter

|

|

|

||||

|

Material

|

STS304&Q235

|

DMK1500-3200

|

DMK1250-4000

|

DMK1500-4000

|

||||

|

Plate Thickness

|

0.4-8MM

|

0.4-8MM

|

0.4-8MM

|

0.4-8MM

|

||||

|

Plate Length X Width

|

1250×3200mm

|

1500×3200mm

|

1250×4000mm

|

1500×4000mm

|

||||

|

Feeding Speed

|

6M/min

|

6M/min

|

6M/min

|

6M/min

|

||||

|

X-axis Motor Power

|

4.5KW

|

4.5KW

|

4.5KW

|

4.5KW

|

||||

|

Y-axis Motor Power

|

1.5KW

|

1.5KW

|

1.5KW

|

1.5KW

|

||||

|

Z-axis Motor Power

|

0.4KW

|

0.4KW

|

0.4KW

|

0.4KW

|

||||

|

Feeding WAY

|

Back Feeding

|

Back Feeding

|

Back Feeding

|

Back Feeding

|

||||

|

Workbench is quenched or not

|

Yes

|

Yes

|

Yes

|

Yes

|

||||

|

Cooling Sprayer

|

Have

|

Have

|

Have

|

Have

|

||||

Recommend Products

Hot Searches