- Product Details

- {{item.text}}

Quick Details

-

Power:

-

As your requirement

-

Dimension(L*W*H):

-

As your requirement

-

Weight:

-

OEM

-

After-sales Service Provided:

-

Overseas service center available, Free spare parts

-

Plate Material:

-

AISI304/316/Ti

-

Gasket Material:

-

NBREPDM/FKM

-

Frame Material:

-

CS/SS

-

Color:

-

Blue

-

OEM:

-

Available

-

Application Industries:

-

Alcohol Plant,Fuel ethanol

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Italy

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GOJE

-

Voltage:

-

220V

-

Power:

-

As your requirement

-

Dimension(L*W*H):

-

As your requirement

-

Weight:

-

OEM

-

After-sales Service Provided:

-

Overseas service center available, Free spare parts

-

Plate Material:

-

AISI304/316/Ti

-

Gasket Material:

-

NBREPDM/FKM

-

Frame Material:

-

CS/SS

-

Color:

-

Blue

-

OEM:

-

Available

-

Application Industries:

-

Alcohol Plant,Fuel ethanol

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Italy

-

Certification:

-

ISO9001

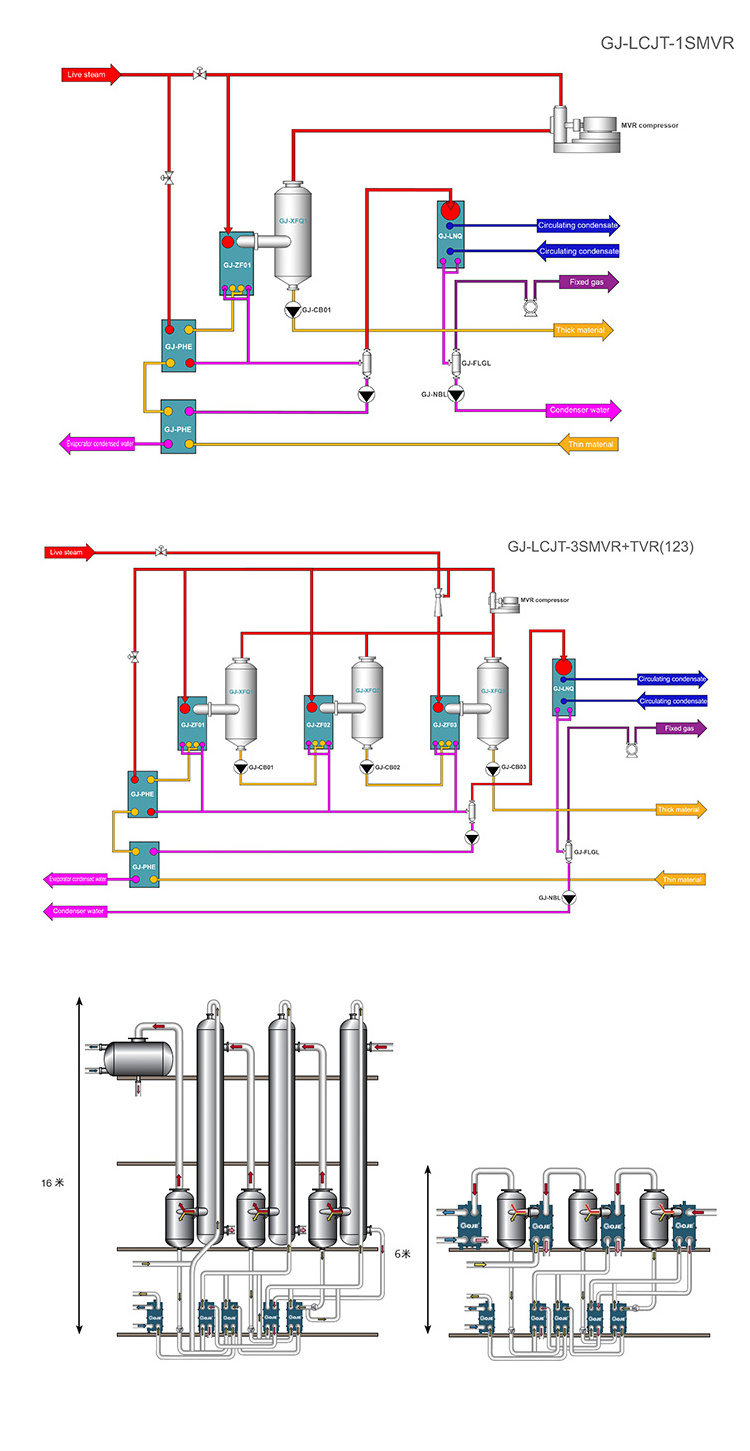

The material conveyed from the preceding stage is preheated to the boiling point temperature of the first-stage evaporator EV01 through the preheating system, and then enters the first-stage evaporator EV01, which is heated by the high-temperature steam from the MVR outlet pipe in the evaporator. The vaporization boils, and then ejects from the mixture outlet of the evaporator in the form of a vapor-liquid mixture at high speed, and tangentially enters the material inlet of the one-effect cyclone XFQ1. In the separator, the droplet is sucked to the wall due to the centrifugal force. The gravity is collected to the bottom and sent to the concentration or density meter by the one-effect material pump CB01. The qualified materials are sent to the product storage tank, and the unqualified materials are returned to the incoming storage tank; the vapor phase is spirally raised, and a small amount of droplets are wrapped. The top set of the juice trap captures back to the bottom of the tank, and the saturated secondary steam is discharged from the outlet at the top of the separator into the MVR inlet. The MVR compressor compresses the secondary steam in the inlet pipe and sends it to the MVR outlet pipe for delivery to the evaporator for heating steam. Excess steam and non-condensable gas in the MVR system enter the plate condenser for condensation and cooling, the condensate is discharged from the system by NB0L, and the non-condensable gas is extracted by the vacuum system. The establishment and maintenance of the system vacuum is accomplished by a vacuum pump or vacuum pump set.

For the multi-effect evaporation process, we adopt different types of evaporator types according to the material conditions: respectively: lifting film, rising film, falling film form:

For the multi-effect evaporation process, we adopt different types of evaporator types according to the material conditions: respectively: lifting film, rising film, falling film form:

Details

W hy Choose us?

1. More than 20 years of experience in the design and manufacture of evaporation systems, which can quickly determine the problems of the evaporation system during operation, and has a data database of practical operations of hundreds of materials.

2. The professional personnel and R&D team of the evaporation department have the most complete plate evaporation type in China, which is satisfied with the process needs of different industries.

3. Product series, rising film, lifting film, and falling film three series of evaporators, gathered in all the advantages of evaporation form, respectively, in different empirical data, is the most advanced and complete professional company in the field of evaporation.

4. The evaporation plate type has the largest single-plate area of the international model and the smallest model to meet different working conditions.

5. Semi-welded imported plate evaporator plate type, leading international technology, to solve the problem of expensive imported equipment and untimely service.

6. Ranked first in the market share of plate evaporation system in the starch sugar industry. China's first brand in the refined sugar market at home and abroad, has rich experience in overseas projects, and has served the project experience of evaporation systems for many countries.

7. The design process is compact and the system energy saving effect is more significant than similar products. And each system has 3D drawings.

8. Experienced on-site commissioning and after-sales service personnel system, VIP quality customer system, 24-hour after-sales guarantee.

9. Provide quality transformation and technical support services for the evaporation system.

10. The susceptible gasket can be used for up to 10 years under normal use.