- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120KW

-

Dimension(L*W*H):

-

18200x10000x19400 mm

-

Weight:

-

10000 kg

-

Product name:

-

concrete mixing plant

-

Capacity:

-

60 m3/h

-

Max aggregate sizes:

-

60/80 mm

-

Discharging height:

-

3800 mm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machine Type:

-

Screw conveyor

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINYU

-

Power:

-

120KW

-

Dimension(L*W*H):

-

18200x10000x19400 mm

-

Weight:

-

10000 kg

-

Product name:

-

concrete mixing plant

-

Capacity:

-

60 m3/h

-

Max aggregate sizes:

-

60/80 mm

-

Discharging height:

-

3800 mm

-

After Warranty Service:

-

Video technical support

Product Description

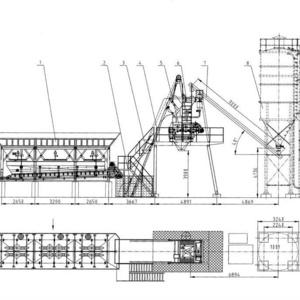

XINYU HZS series concrete batching plant with twin shaft forced mixing concrete mixer is very popular in all the countries and regions. It is stationary with two main types. One is skip hopper feeding and the other one is belt conveyor feeding.

Skip hopper feeding type has the advantages of small area, easy to install and remove. Its price is cheaper and easy to maintain.

Belt conveyor feeding type covers a bigger area and has a very high efficiency of concrete mixing, which is the ideal machine for concrete selling, and big construction such as skyscraper, road and bridge.

Skip hopper feeding type has the advantages of small area, easy to install and remove. Its price is cheaper and easy to maintain.

Belt conveyor feeding type covers a bigger area and has a very high efficiency of concrete mixing, which is the ideal machine for concrete selling, and big construction such as skyscraper, road and bridge.

Product Details

Concrete batching plant consists of batching system, mixer and electric control system, belt conveyor etc, which is professional equipment for ready mix concrete production, such as plasticity/dry concrete.XINYU concrete mixing plant is widely used in small and medium construction products, road, bridge project, and concrete prefabrication factory.

Project

Specification

|

Model

|

HZS60

|

HZS90

|

HZS120

|

HZS150

|

|||

|

Capacity

|

60m3/h

|

90m3/h

|

120m3/h

|

180m3/h

|

|||

|

Mixing system

|

Twin shaft concrete mixer

|

|

|

|

|||

|

Aggregate feeder

|

Belt conveyor

|

|

|

|

|||

|

Discharging height

|

3800mm

|

3800mm

|

3900mm

|

4000mm

|

|||

|

After-sale service

|

Erection & commissioning, operator training

|

|

|

|

|||

|

Warranty

|

12 months after erection

|

|

|

|

|||

|

Concrete mixer

|

JS1000

|

JS1500

|

JS2000

|

JS3000

|

|||

|

Discharging volume

|

1000L

|

1500L

|

2000L

|

3000L

|

|||

|

Charging volume

|

1500L

|

2250L

|

3000L

|

4500L

|

|||

|

Mixing circle

|

72s

|

|

|

|

|||

|

Max. mixing size

|

80/60mm

|

|

|

|

|||

|

Aggregate batching machine

|

PLD1600

|

PLD2400

|

PLD3200

|

PLD4800

|

|||

|

Storage bins quantity

|

2 or 3 or 4 sorts

|

3 or 4 sorts

|

3 or 4 sorts

|

3 or 4 sorts

|

|||

|

Aggregate scale hopper

|

1600L

|

2400L

|

3200L

|

4800L

|

|||

|

Weighing system

|

Water, Cement, Additive

|

|

|

|

|||

|

Weighing precision

|

±1%

|

|

|

|

|||

|

Air system

|

Air compressor, etc

|

|

|

|

|||

|

Control system type

|

Computer auto-control module (PLC can be optional item)

|

|

|

|

|||

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches