- Product Details

- {{item.text}}

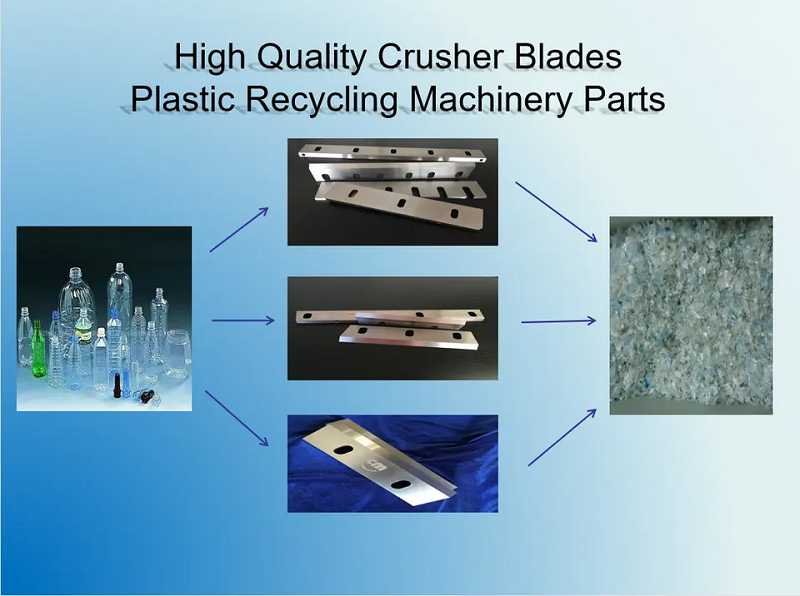

Quick Details

-

Brand Name:

-

TOP WE

-

Feature:

-

High Speed, Straight Smooth Edge

-

Packing:

-

Durable ply-wooden box packing

-

Size:

-

Customized

-

Material:

-

D2,M2,52100 or customized

-

Tolerance:

-

Exceed OEM Specification

-

OEM Service:

-

Support

-

Application:

-

Manufacturing Plant

-

Spare Parts Type:

-

blade

-

Usage:

-

Crusher Machine Knife

-

Name:

-

Shredder Machine

Quick Details

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

blade

-

Type:

-

Shredder Blade

-

Brand Name:

-

TOP WE

-

Feature:

-

High Speed, Straight Smooth Edge

-

Packing:

-

Durable ply-wooden box packing

-

Size:

-

Customized

-

Material:

-

D2,M2,52100 or customized

-

Tolerance:

-

Exceed OEM Specification

-

OEM Service:

-

Support

-

Application:

-

Manufacturing Plant

-

Spare Parts Type:

-

blade

-

Usage:

-

Crusher Machine Knife

-

Name:

-

Shredder Machine

|

Product Name

|

Quality Wood Chipper Blade Cutting Wood Blade For Wood Industry

|

|

Size

|

Customized

|

|

Material

|

D2 , 52100, M2 or customized

|

|

Surface Roughness

|

0.2 mm

|

|

Hardness

|

59-61 HRC

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Q: What Steel Grades do you use to manufacture Industrial Blades?

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will assess your cutting requirements and working conditions to help you find the longer-life solution.

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable. Never a defective product will be delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 15 working days. There are also stock of knives. Please contact us to discuss your requirements.

Q: What is your payment terms?

A: Payment by TT, L/C are all acceptable.

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will assess your cutting requirements and working conditions to help you find the longer-life solution.

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable. Never a defective product will be delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 15 working days. There are also stock of knives. Please contact us to discuss your requirements.

Q: What is your payment terms?

A: Payment by TT, L/C are all acceptable.

Hot Searches