- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

138 - 380 mm

-

Ejector Number:

-

5

-

Ejector Stroke(mm):

-

85 mm

-

Ejector Force(kN):

-

25.4 kN

-

Theoretical Shot Volume(cm³):

-

201 cm³

-

Injection Rate (g/s):

-

120 g/s

-

Injection Weight (g):

-

183 g

-

Screw Speed (rpm):

-

250 - 260 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

18.4

-

Distance between Tie Bars:

-

360x360 mm

-

Weight (KG):

-

3200

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

360 mm

-

Model Number:

-

HJ-950A, HJ-950A

-

Brand Name:

-

HUAN

-

Power (kW):

-

11 kW

-

Blow Moulding Type:

-

Injection molding machine

-

Automatic:

-

Yes

-

Material:

-

pe/pvc/pp/abs/HDPE

-

Machine type:

-

Injection molding machine for plastic product

-

Production:

-

cap Injection molding machine

-

Screw diameter:

-

Customized

-

Machine size:

-

4.25*1.2*1.8m

-

Plastic Type:

-

Thermoplastic

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE,ISO

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

360mm

-

Distance between Tie Bars(Height)(mm):

-

360mm

-

Plasticizing Capacity(g/s):

-

18

-

Mold Height(mm):

-

138 - 380 mm

-

Ejector Number:

-

5

-

Ejector Stroke(mm):

-

85 mm

-

Ejector Force(kN):

-

25.4 kN

-

Theoretical Shot Volume(cm³):

-

201 cm³

-

Injection Rate (g/s):

-

120 g/s

-

Injection Weight (g):

-

183 g

-

Screw Speed (rpm):

-

250 - 260 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

18.4

-

Distance between Tie Bars:

-

360x360 mm

-

Weight (KG):

-

3200

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

360 mm

-

Model Number:

-

HJ-950A, HJ-950A

-

Brand Name:

-

HUAN

-

Power (kW):

-

11 kW

-

Blow Moulding Type:

-

Injection molding machine

-

Automatic:

-

Yes

-

Material:

-

pe/pvc/pp/abs/HDPE

-

Machine type:

-

Injection molding machine for plastic product

-

Production:

-

cap Injection molding machine

-

Screw diameter:

-

Customized

-

Machine size:

-

4.25*1.2*1.8m

-

Plastic Type:

-

Thermoplastic

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE,ISO

Product Description

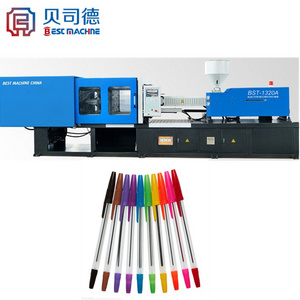

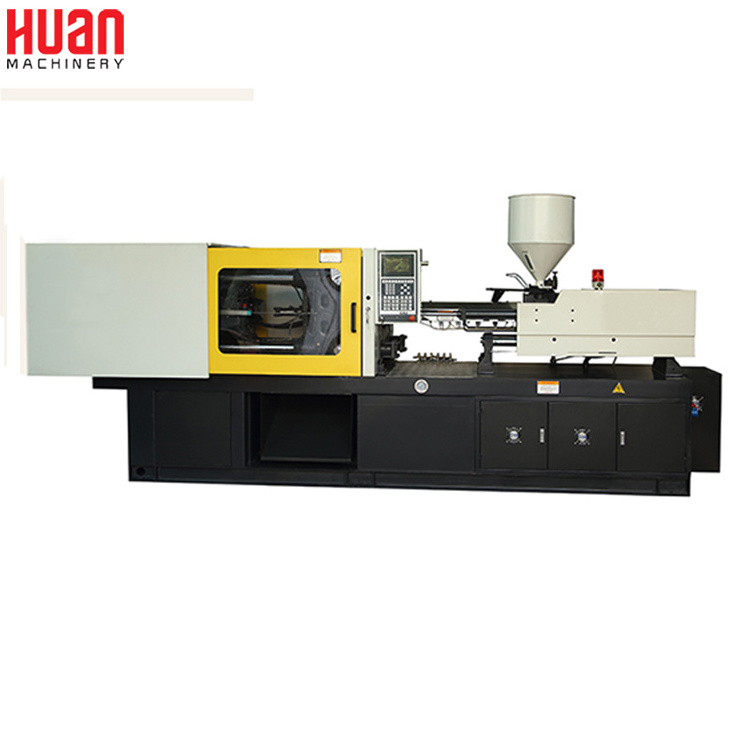

High Quality Full Automatic horizontal plastic injection moulding plastic pen shell making machine for color pen ball pen pencil

Auto transparent plastic oil barrel bucket with screw on lids injection molding mould machine

Injection molding machine is used for producing different plastic products PP, PVC PET

material, such as oil bottle cap,cosmetic bottle cap,milk bottle cap,lotion bottle cap and so on. We could offer suitable model injection machine according to customer’s products and requirements.

Our machine main feature: big clamping force, big shot weight and big tie bar space.

Warmly welcome to contact us, we are pleasure to discuss with you about more details.

material, such as oil bottle cap,cosmetic bottle cap,milk bottle cap,lotion bottle cap and so on. We could offer suitable model injection machine according to customer’s products and requirements.

Our machine main feature: big clamping force, big shot weight and big tie bar space.

Warmly welcome to contact us, we are pleasure to discuss with you about more details.

|

INJECTION UNIT HJ-950A

|

|

|

|

|

||||

|

SCREW DIAMETER

|

mm

|

30

|

35

|

40

|

||||

|

SCREW L/D RATIO

|

L/D

|

24.5

|

21

|

18.4

|

||||

|

Theoretical Shot Volume

|

cm^3

|

113

|

154

|

201

|

||||

|

SHOW WEIGHT(PS)

|

g

|

103

|

140

|

183

|

||||

|

INJECTION PRESSURE

|

Mpa

|

249

|

183

|

140

|

||||

|

THEORETICAL INJECTION RATE(PS)

|

g/s

|

67.5

|

91.8

|

120

|

||||

|

PLASTICISING CAPACITY

|

g/s

|

8.3

|

12.5

|

18

|

||||

|

SCREW TORQUE

|

N.m

|

510

|

|

|

||||

|

MAX.SCREW ROTATE SPEED

|

r/min

|

260

|

|

|

||||

|

INJECTION STROKE

|

mm

|

160

|

|

|

||||

|

CLAMPING UNIT

|

|

|

|

|

||||

|

MAX.CLAMPING FORCE

|

KN

|

950

|

|

|

||||

|

MAX.OPENING STROKER

|

mm

|

340

|

|

|

||||

|

SPACE BETWEEN TIE BARS

|

mm

|

360×360

|

|

|

||||

|

MOULD HEIGHT

|

mm

|

135~380

|

|

|

||||

|

MAX.DAYLIGHT

|

mm

|

720

|

|

|

||||

|

EJECTOR FORCE

|

kn

|

25.4

|

|

|

||||

|

EJECTOR STROKE

|

mm

|

85

|

|

|

||||

|

EJECTOR QUANTITY

|

pc

|

5

|

|

|

||||

|

OTHER

|

|

|

|

|

||||

|

PUMP MOTOR POWER

|

KW

|

11

|

|

|

||||

|

PUMP PRESSURE

|

Mpa

|

16

|

|

|

||||

|

HEATING POWER

|

KW

|

7.3

|

|

|

||||

|

HEATING ZONE

|

|

4

|

|

|

||||

|

SIZE

|

m

|

4.25×1.2×1.8

|

|

|

||||

|

NET WEIGHT

|

t

|

3.2

|

|

|

||||

|

OIL TANK CAPACITY

|

L

|

260

|

|

|

||||

|

INTERNATIONAL DESIGNATION

|

|

950-280

|

|

|

||||

Application

Injection molding machine can produce plastic caps with different shapes,different size.If you have any question,feel free to contact us huanmachinery @vip.163.com.

You could send the photos which you want to produce,we will recommed the suitable machine to you.

Product Details

Clamping structure:

New type 5-point toggle device, stable movement and gentle shock, high pressure clamping and high quality mold plate; Wear-resistant guide for moving platen, transducer control clamping stroke;Automatic centralized lubrication system with far pressure detector.

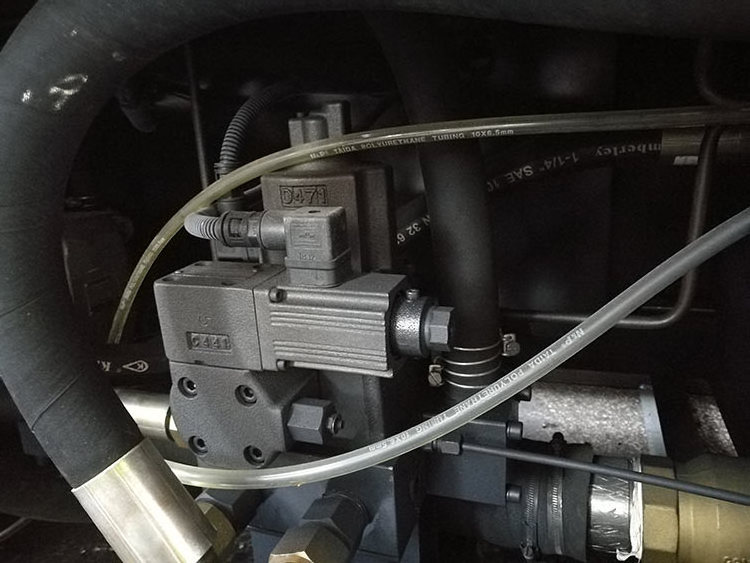

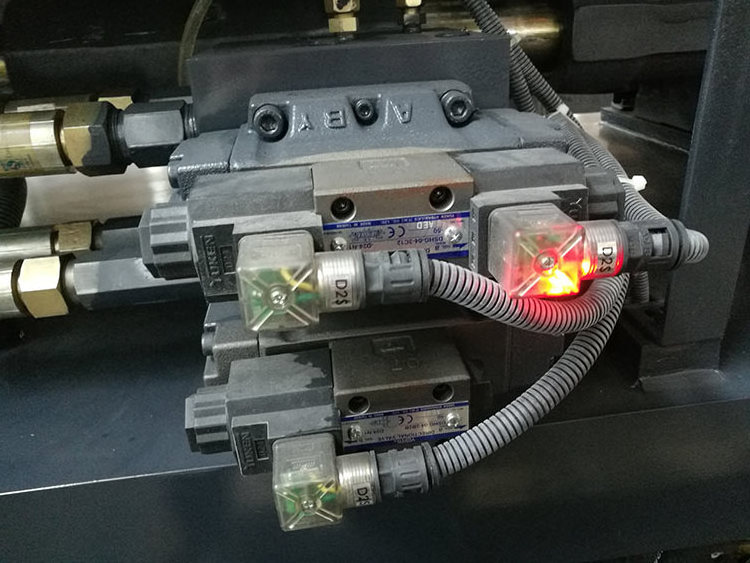

Hydraulic unit:

Proportional pressure and flow control with the advantage of fine adjustment and high precision, hydraulic valve and pump control the action of machine;

Injection system:

High strong screw an barrel with long service life, good plasticizing effort, traducer control injection stroke, injection carriage can be generally used with the function of slacking,

re-feeding or fixed-feeding.

Control unit:

Touch screen+PLC+electrical parts, control whole machine, adjust data through touch screen, electrical parts protect important component like heater...

Cap mould for injection molding machine

The cap mould has hot runner type and cold runner type.We produced the cap mould as customers' requirements,in order to equipped with injection molding machine.

Recommend Products

Our service

Choosing the suitable machine:

We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Packing & Shipping

1) The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires.

2) The electric controlling parts and spare parts are loaded separately in wooden box.

3) The auxiliary equipments are packaged in wooden box as well.

4) All wooden material is fumigation certificated and safe for exporting to all over the world.

Related products

Any requirement,please feel free to contact us.

huanmachinery@ vip.163.com

Hot Searches