- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Industry

-

Grade:

-

Nickel based

-

Ni (Min):

-

72%

-

Model Number:

-

Inconel 600

-

Brand Name:

-

DLX

-

Material:

-

Nickel based alloy,Inconel 600

-

Resistance:

-

1.5

-

Density:

-

8.43g/cm3

-

Chemical composition:

-

Ni,Cr,Mn,Fe

-

Melting Point:

-

1393-1427°C

-

Ultimate strength:

-

760

-

Surface:

-

Bright Annealed

-

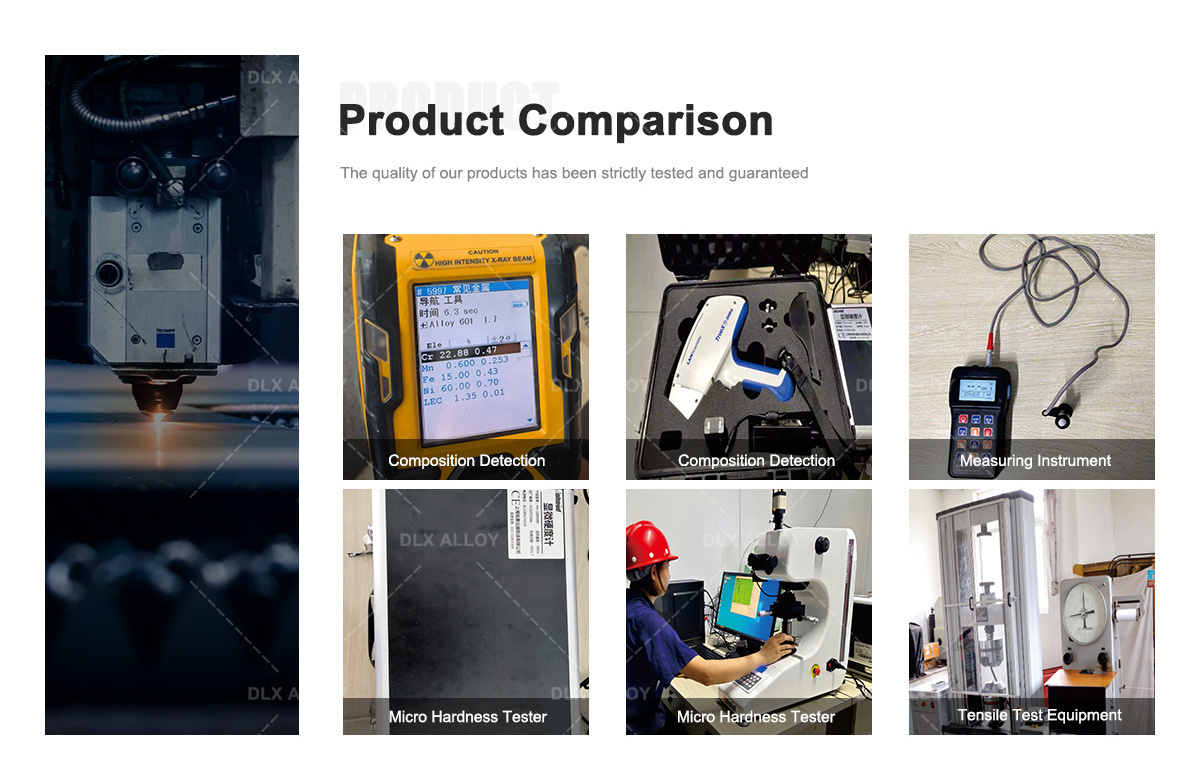

Certificate:

-

ISO9001

-

MOQ:

-

10kg

-

Delivery Time:

-

7-20 Days

Quick Details

-

Resistance (μΩ.m):

-

1.5

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

1267

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Industry

-

Grade:

-

Nickel based

-

Ni (Min):

-

72%

-

Model Number:

-

Inconel 600

-

Brand Name:

-

DLX

-

Material:

-

Nickel based alloy,Inconel 600

-

Resistance:

-

1.5

-

Density:

-

8.43g/cm3

-

Chemical composition:

-

Ni,Cr,Mn,Fe

-

Melting Point:

-

1393-1427°C

-

Ultimate strength:

-

760

-

Surface:

-

Bright Annealed

-

Certificate:

-

ISO9001

-

MOQ:

-

10kg

-

Delivery Time:

-

7-20 Days

Product Description

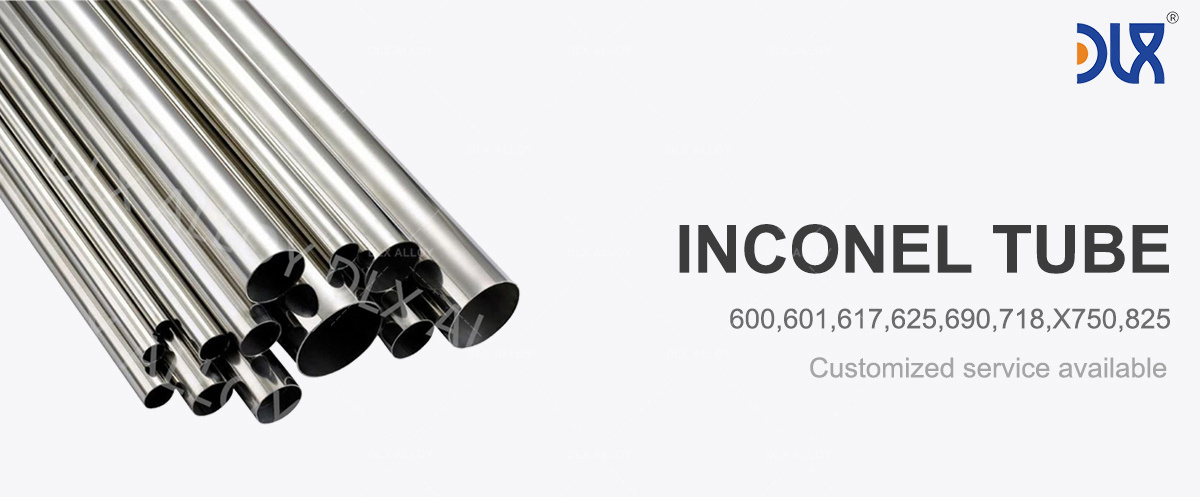

Inconel Series

Inconel Pipe 600 601 625 690 718 Nickel Alloy Manufacturer Seamless Inconel Tube / Pipe Nickel-chromium-iron inconel alloy 600 (UNS N06600/W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

The alloy is used extensively in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

The alloy is used extensively in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

Size dimension range:

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Inconel series: 600,601,617,625,690,718,X-750,825

Inconel Chemical Composition

|

Item

|

600

|

601

|

617

|

625

|

690

|

718

|

X750

|

825

|

|

C

|

≤0.15

|

≤0.1

|

0.05-0.15

|

≤0.08

|

≤0.05

|

≤0.08

|

≤0.08

|

≤0.05

|

|

Mn

|

≤1

|

≤1.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.35

|

≤1

|

≤1

|

|

Fe

|

6-10

|

rest

|

≤3

|

rest

|

7-11

|

rest

|

5-9

|

≥22

|

|

P

|

≤0.015

|

≤0.02

|

≤0.015

|

--

|

--

|

--

|

--

|

--

|

|

S

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.01

|

≤0.01

|

≤0.03

|

|

Si

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.5

|

|

Cu

|

≤0.5

|

≤1

|

--

|

≤0.3

|

≤0.5

|

≤0.3

|

≤0.5

|

1.5-3

|

|

Ni

|

≥72

|

58-63

|

≥44.5

|

50-55

|

≥58

|

50-55

|

≥70

|

38-46

|

|

Co

|

--

|

--

|

10-15

|

≤10

|

--

|

≤1

|

≤1

|

--

|

|

Al

|

--

|

1-1.7

|

0.8-1.5

|

≤0.8

|

--

|

0.2-0.8

|

0.4-1

|

≤0.2

|

|

Ti

|

--

|

--

|

≤0.6

|

≤1.15

|

--

|

--

|

2.25-2.75

|

0.6-1.2

|

|

Cr

|

14-17

|

21-25

|

20-24

|

17-21

|

27-31

|

17-21

|

14-17

|

19.5-23.5

|

|

Nb+Ta

|

--

|

--

|

--

|

4.75-5.5

|

--

|

4.75-5.5

|

0.7-1.2

|

--

|

|

Mo

|

--

|

--

|

8-10

|

2.8-3.3

|

--

|

2.8-3.3

|

--

|

2.5-3.5

|

|

B

|

--

|

--

|

≤0.006

|

--

|

--

|

--

|

--

|

--

|

Recommend Products

Other Products Series

FeCrAl Alloy

: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy : Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy : NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding wire : ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Thermocouple alloy : K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Inconel alloy : Inconel 600,601,617,X-750,625,690,718,825.

Incoloy alloy : Incoloy 800,800H,800HT,825,925.

Hastelloy alloy : HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy : Monel 400,K500.

High-temperature alloy : A-286,Nimonic80A,Nimonic 90,GH1140,GH3625,GH3536,GH4169

Thermal spray alloy : Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

NiCr Alloy : Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy : NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding wire : ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Thermocouple alloy : K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Inconel alloy : Inconel 600,601,617,X-750,625,690,718,825.

Incoloy alloy : Incoloy 800,800H,800HT,825,925.

Hastelloy alloy : HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy : Monel 400,K500.

High-temperature alloy : A-286,Nimonic80A,Nimonic 90,GH1140,GH3625,GH3536,GH4169

Thermal spray alloy : Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

Hot Searches