- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

Reducing

-

Head Code:

-

Round

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

SDS

-

Model Number:

-

OEM

-

Product name:

-

Ductile Iron Welding Neck Flange

Quick Details

-

Type:

-

Flange

-

Material:

-

Iron

-

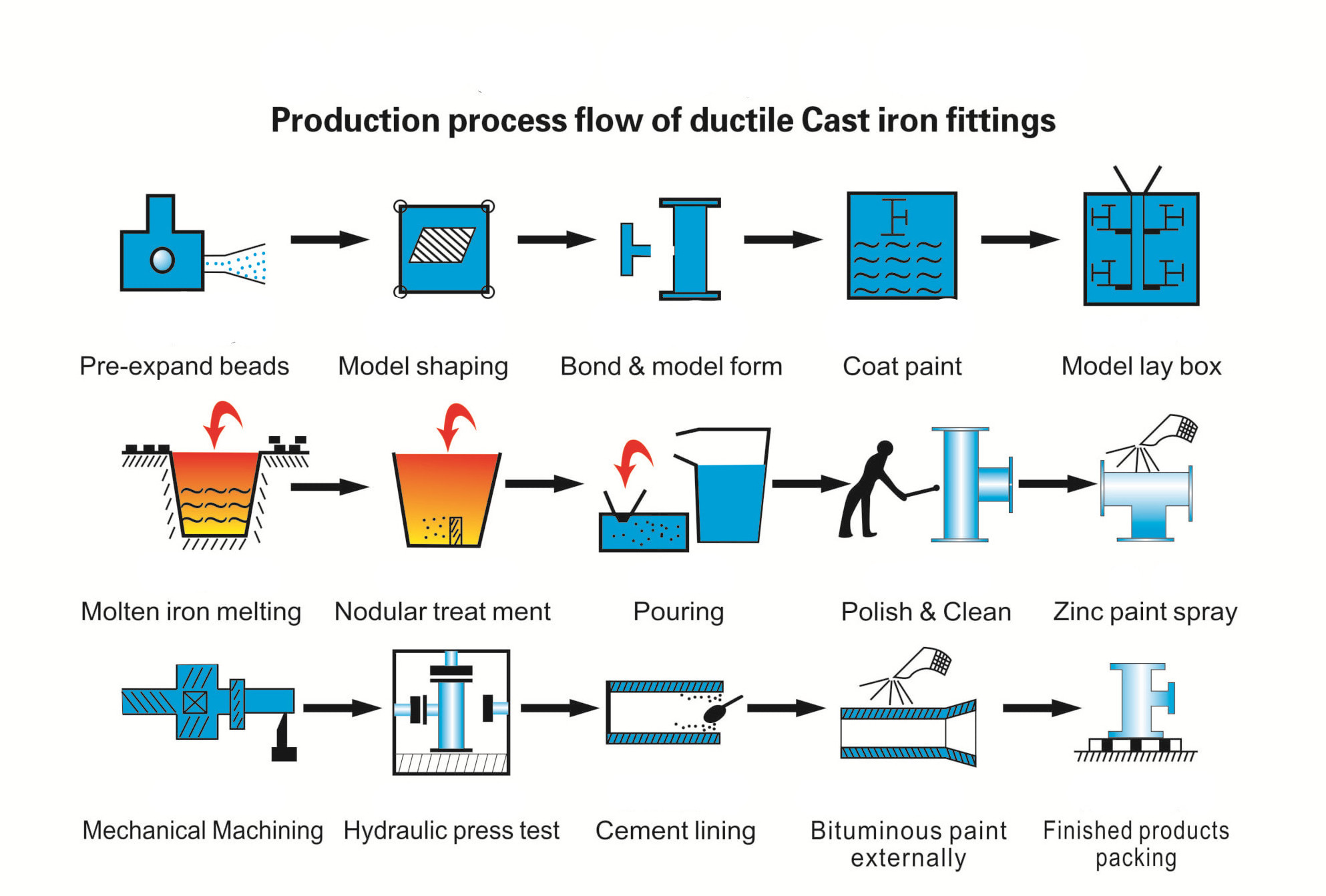

Technics:

-

Casting

-

Shape:

-

Reducing

-

Head Code:

-

Round

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

SDS

-

Model Number:

-

OEM

-

Product name:

-

Ductile Iron Welding Neck Flange

Ductile Iron Flange Bend

Product Description

Ductile Iron Flange Bend

The double Flanged bend can be used widely in the instant pipes in these fields: water supply and sewerage, gas

transfer, oil transfer, chemical industry, metallurgic industry, mineral industry, water power, electric power, marine.

| Item | Description | Standard |

| Nominal Size | As your requirements | EN545:2010, AWWA C110 |

| Class | K12, K14 | BS4772, ISO2531, EN598 |

| Internal Coating | Cement Mortar, FBE | ISO4179:2005, ANSI AWWA C104 |

| Ceramic Epoxy, Pu | BS EN15189 | |

| Package | Wooden Pallet/Wooden Case |

Product Details

|

Nominal Diameter DN |

T Type Mass(kg) |

Nominal Diameter DN |

T Type Mass(kg) |

|||

|

PN10 |

PN16 |

PN25 |

PN10 | PN16 | ||

|

80 |

7.4 |

7.4 |

7.4 |

900 |

235 | 258 |

|

100 |

9 |

9 |

9.5 |

1000 |

293 | 324 |

|

125 |

11.5 |

11.5 |

12..1 |

1100 |

19.2 | 413.8 |

|

150 |

14.2 |

14.2 |

15.2 |

1200 |

456 | 521 |

|

200 |

20.5 |

20.5 |

22 |

1400 |

654 | 723 |

|

250 |

28 |

27.5 |

31.5 |

1500 |

773 | 857 |

|

300 |

37 |

36.5 |

42 |

1600 |

887 | 989 |

|

350 |

45 |

48 |

56 |

1800 | 1125 | 1251 |

|

400 |

55 |

60 |

71 |

2000 |

1414 | 1567 |

|

450 |

70.5 |

78 |

88.5 |

2100 |

||

|

500 |

78 |

93 |

104 |

2200 | 1767 | 1934 |

| 600 | 108 | 135 | 149 | 2400 | 2150 | 2352 |

| 700 | 144 | 159 | 2600 | 2563 | 2798 | |

| 800 | 189 | 208 | ||||

1) Internal Coating

Pipes are lined internally with Portland cement (Sulphate resistant type V). Cement is applied by centrifugal process

in compliance with ISO 4179. Thickness of cement is according to ISO & BSEN standards.

SDS can offer any different specification or coating as per customer requirement.

2) External Coating

Pipes are coated externally by pure metallic Zinc (minimum 99.995 purity) at a rate of 200g/m 2 , which represents 50%

more than the requirement of ISO 8179 (DN 900 mm and above 130g/m 2 or 200g/m 2 as per customer request). Zinc

is then covered by 120 microns of bituminous paint as per ISO 8179-1.

SDS can offer any different specification or coating as per customer requirement.

3) Cement Lining

The lining is then cured under controlled temperature and humidity giving it the optimum mechanical strength and also

producing a very smooth surface which reduces head losses and guarantees long-term hydraulic efficiency.

Cement lining is an acive coating, when the pipe is filled, the mortar gradually absorbs water, which becomes enriched

in Alkaline substances. Consequently, it is non-corrosive when it reaches the proximity of the metal wall. Also, cement

lining demonstrate the ability to withstand limited pipe deflection and good performance under high top loads.

Product Application

Package & Delivery

Package of Flange Socket

1) Generally our package is shown as the picture.

2) We can package as your requirements.

Delivery time

Our delivery time: regular within 30--35 days after order confirmed.