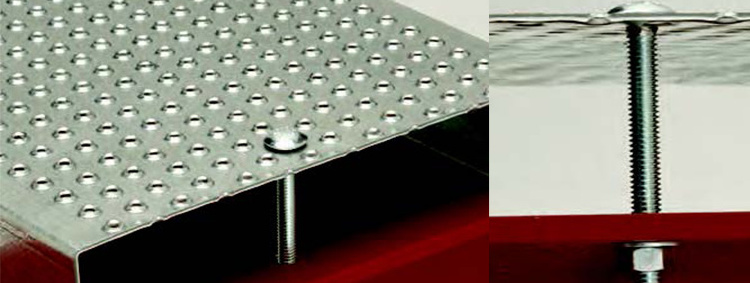

2. Mark and drill holes in the I-beam and Traction Tread plank.

3. Secure the Traction Tread plank by running a bolt through it and the I-beam, tightening with a washer and nut.

4. Test for stability and adjust if necessary.

|

Material options

|

Carbon steel

|

11 gauge

|

Load capacity

|

5.0 lbs./sq. ft.

|

|

|

|

12 gauge

|

|

4.3 lbs./sq. ft.

|

|

|

|

13 gauge

|

|

3.8 lbs./sq. ft.

|

|

|

|

14 gauge

|

|

3.1 lbs./sq. ft.

|

|

|

|

16 gauge

|

|

2.5 lbs./sq. ft.

|

|

|

Aluminum alloy 5052-H32:

|

.125"

|

|

1.6 lbs./sq. ft.

|

|

Type

|

Ladder rungs, Planks, Stair treads, Scaffolding planks

|

|

|

||

|

Material

|

Galvanized sheet:

|

11, 13, 16 gauge

|

|

||

|

|

HRPO carbon steel:

|

11, 12, 13, 14, 16 gauge

|

|

||

|

|

5052-H32 aluminum:

|

0.125"

|

|

||

|

|

Stainless steel 304 or 316L:

|

14, 16 gauge

|

|

||

|

Traction tread ladder rungs

|

Hole type:

|

2-hole, 3-hole, 4-hole

|

|

||

|

|

Width:

|

2-hole: 1-1/4", 3-hole: 1-5/8", 4-hole: 2-1/4"

|

|

||

|

|

Depth:

|

2-hole: 1-1/2", 3-hole: 1-1/8", 4-hole:1-1/2"

|

|

||

|

|

Length:

|

As request.

|

|

||

|

Traction tread plank grating

|

Hole diameter:

|

3/8"

|

|

||

|

|

Width:

|

7", 10", 12"

|

|

||

|

|

Length:

|

120", 144"

|

|

||

|

|

Channel depth:

|

1-1/2", 2"

|

|

||

|

Traction tread stair treads

|

Width:

|

7", 10", 12"

|

|

||

|

|

Channel depth:

|

1-1/2", 2"

|

|

||

|

|

Length:

|

As request

|

|

||

|

Accessories:

|

carriage bolts, flat washer, Hex nut, carrier plate.

|

|

|

||

|

Standard:

|

BS 4592-0, BS 4592-1, BS 4592-3

|

|

|

||

|

Surface treatmen:

|

galvanized, hot rolling, pickling.

|

|

|

||

|

Package

|

packed with plastic film, shipped by pallets or according to customers' requirements.

|

|

|

||