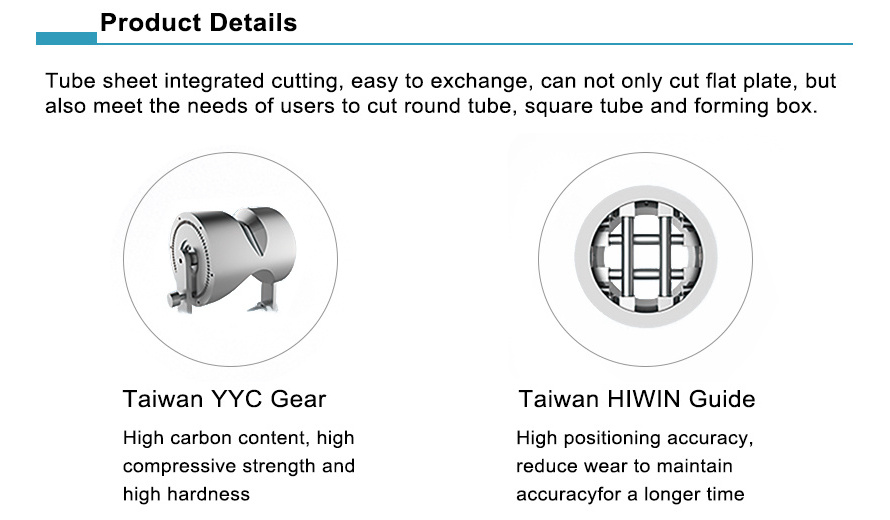

Then by the large-scale precision gantry machining center for precision machining. Stable and reliable bed, no deformation,

to ensure long-term cutting accuracy and machine stability.

Optional casting

machine bed.