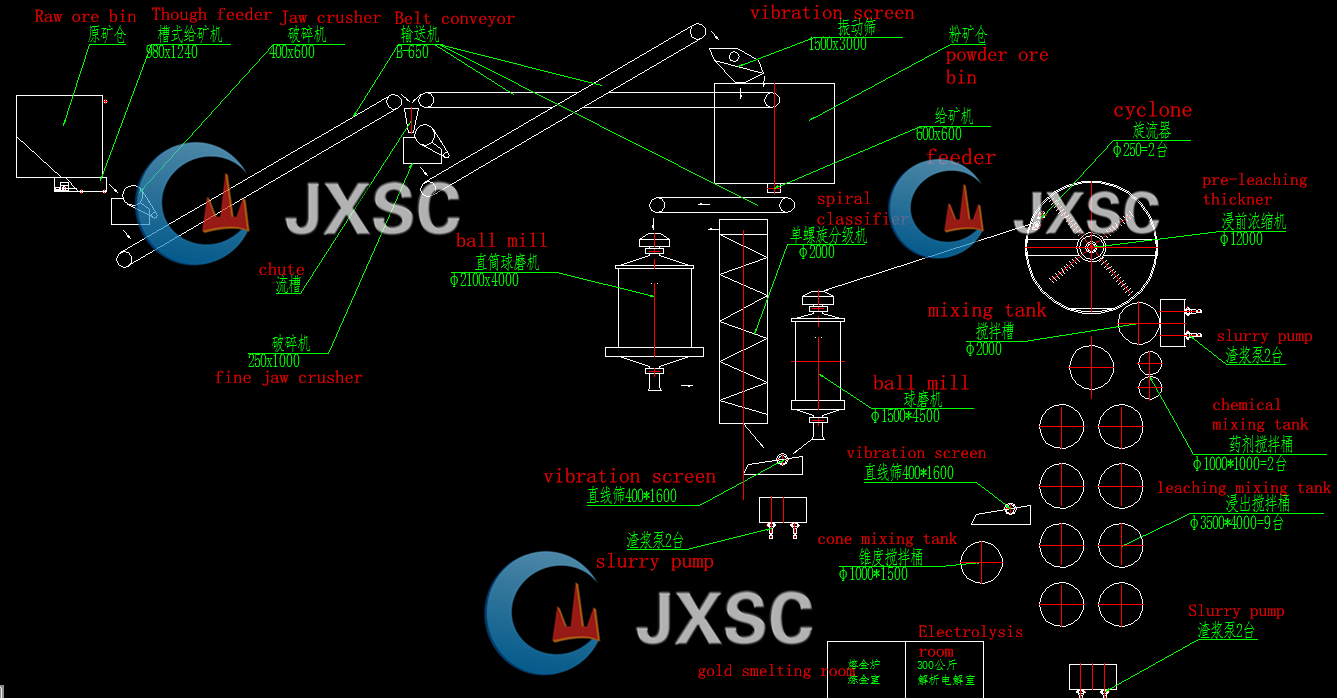

Carbon-in-pulp (CIP) is the sequential leach then absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to dissolve gold into solution. In the absorption stage, this solution flows through several agitated tanks containing activated carbon. Gold absorbs on to the activated carbon, which flows counter-current to the pulp, while screens separate the barren pulp from the gold-loaded carbon.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Gold Leaching Plant(CIP/CIL),Heap Leach

-

Application:

-

Rock Gold Ore,Dump Ore, Gold Tailing

-

Crusher:

-

Jaw Crusher/Hammer Crusher/Cone Crusher

-

Grinding Machine:

-

Ball Mill

-

Leaching Tank:

-

3500mm diameter*4000mm

-

Adsorption tank:

-

3000mm diameter*4000mm

-

Thickener:

-

6000mm diameter

-

Elution & Electrolysis system:

-

300kg capacity

-

Solution for Tailing dewatering system:

-

high pressure slurry pump+ plate filter press

-

Installation:

-

Send engineer to mine site for installation

Quick Details

-

Weight (KG):

-

20000

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Product name:

-

Gold Leaching Plant(CIP/CIL),Heap Leach

-

Application:

-

Rock Gold Ore,Dump Ore, Gold Tailing

-

Crusher:

-

Jaw Crusher/Hammer Crusher/Cone Crusher

-

Grinding Machine:

-

Ball Mill

-

Leaching Tank:

-

3500mm diameter*4000mm

-

Adsorption tank:

-

3000mm diameter*4000mm

-

Thickener:

-

6000mm diameter

-

Elution & Electrolysis system:

-

300kg capacity

-

Solution for Tailing dewatering system:

-

high pressure slurry pump+ plate filter press

-

Installation:

-

Send engineer to mine site for installation

Metal recovery or concentration by adsorption on activated carbon has been the dominant process for gold extraction after leaching by cyanide in aerated alkaline slurry. The continuous processes of gold recovery by adsorption on activated carbon in agitated tanks, namely the carbon-in-pulp (CIP) and the carbon-in-leach (CIL)processes, have been widely used since the 1970s.

In the CIL (Carbon in Leach) or CIP (Carbon in Pulp) plants while the precious metals are being dissolved by the cyanide solution in the large volume tanks the dissolved metals are adsorbed by the active carbon. These processes are generally preferred for the relatively high grade and lower reserve ore types with very fine graded precious metals.

The major difference between the CIL and CIP processes is; during the CIL process both cyanide leaching and carbon adsorption take place in the same tanks but in the CIP process first leaching occurs in the first couple of tanks then carbon adsorption take place in the following tanks while leaching continues. In all of these tanks agitation and air sparging is available.

Successful Case We Have Done:

|

Model

|

Tank Spec.

Diameter × Height (mm). |

Effective Volume (m3)

|

Impeller Rotation Speed (r.p.m)

|

Impeller Diameter (mm)

|

Power (kW)

|

Tank Weight (kg)

|

Total Weight (kg)

|

|

LT2.0×2.5

|

2000×2500

|

6

|

52

|

909

|

2.2

|

1609

|

2190

|

|

LT2.5×3.15

|

2500×3150

|

13.14

|

|

935

|

|

2450

|

3180

|

|

LT3.0×3.15

|

3000×3150

|

18.93

|

43

|

1130

|

4

|

3530

|

4260

|

|

LT3.0×3.5

|

3000×3500

|

21

|

|

|

|

3298

|

4400

|

|

LT3.15×3.55

|

3150×3550

|

24

|

|

1260

|

|

3510

|

4560

|

|

LT3.5×3.5

|

3500×3500

|

30

|

52

|

1310

|

5.5

|

3560

|

5110

|

|

LT3.55×4.0

|

3550×4000

|

33.6

|

43

|

|

|

4320

|

5100

|

|

LT4.0×4.5

|

4000×4500

|

48

|

35

|

1750

|

7.5

|

6495

|

7652

|

|

LT4.5×5.0

|

4500×5000

|

71.57

|

|

1750

|

|

8752

|

10990

|

|

LT5.0×5.6

|

5000×5600

|

98

|

31

|

2046

|

11

|

8896

|

14422

|

|

LT5.5×6.0

|

5500×6000

|

112

|

|

2100

|

|

12632

|

18912

|

Jiangxi walker Machinery Co., Ltd,

are a professional manufacturer of complete set mining equipment, a sub-company of JXSC mine machinery factory in Jiangxi province.

We are very professional at providing complete set processing equipment for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, etc. As well as complete set small lab mining machines.

Our Main product including trommel screen, trommel scrubber, shaking table, spiral chute separator, jig machine, centrifugal concentrator, sluice box, vibration screen, jaw crusher, hammer crusher, ball mill, flotation machine, spiral classifier. as well as complete set small laboratory mining equipment.

Our main market is in Africa, South Amercia, Southeast Asia, Asia,ect. Our cooperated customers cover Mali, Ghana, Sudan , Uganda, Mozambique, Suriname, Zambia, Nigeria, Cameroon, Madagascan, Malasia, Indonesia, Korea, Philippines, Monglia, Singapore, India, Mexico, Brazil, Chile, Peru, Spain, Canada, Australia, U.S, UAE, etc.

Plant and machine processing capacity can be customized from 1TPH to 300TPH, and accept OEM service.

Exhibition & Fair

Our company have attended many mining fairs, in Ghana, Nigeria, South Africa, Peru, Indonesia, Russia, Mongolia, U.S etc. Our footprint all over the continents just wanna serve our clients well. Moreover, we have an overseas office in Tanzania , the service can cover the whole Africa continent , pre-sales prospecting, testing, after-sales installation are available and easier.

1.How is the quality of your products?(mining equipment/machine)

Answer:

Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.How about the Guarantee:

Answer:

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.What is the price?

Answer:

It's different from each machines, trommel scrubber, trommel screen, shaking table, jig machine separator, centrifugal concentrator, spiral chute, vibrating feeder, cone crusher, jaw crusher, impact crusher, sand making machine etc. For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.If you can help to make the flowchart?

Answer: Yes, sure. We'de will to make the flowchart design accroding to each clients mineral situation, totally for FREE!

Moreover, our engineer can go abroard guiding the installation.

5.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.de bottle oil bottle cosmetics, wide-mouth