- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V /220V/440V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

3 years

-

Weight:

-

customized

-

Certification:

-

ISO9001:2008

-

Product name:

-

China Foundry Hydraulic Multi Contact Molding Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Hydraulic Multi-Contact Molding Machine

-

Brand Name:

-

HENGLIN

-

Voltage:

-

380V /220V/440V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Warranty:

-

3 years

-

Weight:

-

customized

-

Certification:

-

ISO9001:2008

-

Product name:

-

China Foundry Hydraulic Multi Contact Molding Machine

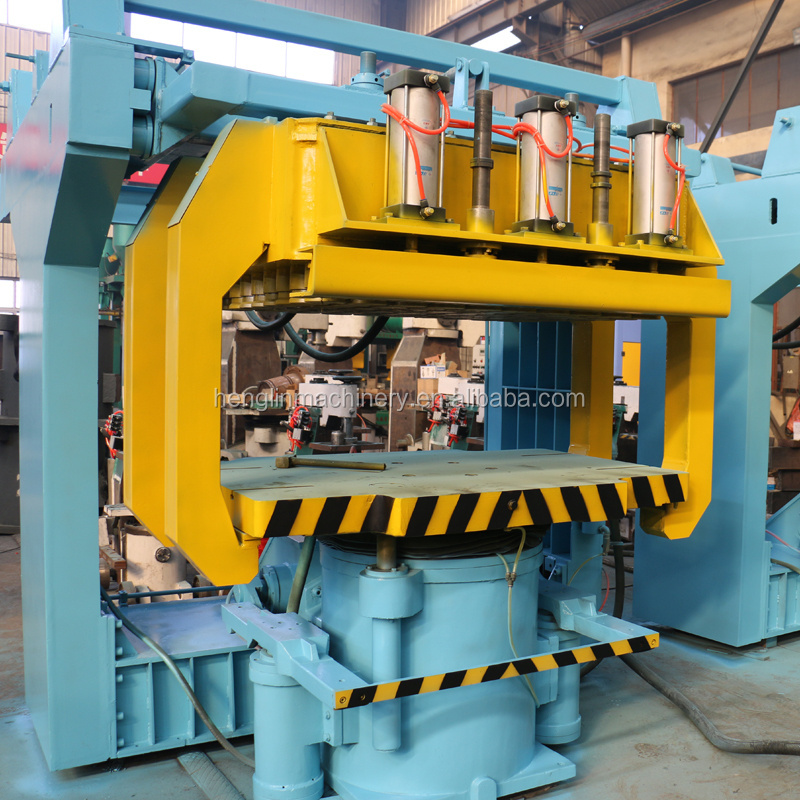

China Foundry Hydraulic Sand Casting Multi Contact Molding Machine for Manhole Cover Production

1. Moderate pressure, no special requirements for sand, and the number of contacts more than 60, suitable for complex model modeling.

2. During compaction, the frame is free of force. The contacts extend downward, the pressure strength is the internal force of compaction.

3. The effect of shock compaction is good. The hardness of the sand mould is high and even.

4. This machine adopts the spring full buffer pneumatic micro vibration mechanism, so it has no special requirement for the foundation, and the mould lifting adopts the connecting rod.

5. Synchronous shaft structure, speed regulation of pneumatic oil, good mould synchronization with free speed control.

1. Various shot blasting machine, eco-friendly dust collector, molding and core shooting equipment, sand processing line and automated modeling line.

2. We offer OEM&ODM service to meet all your requirements.

3. Engineeres are available to guide the installation and take care of other problems.

4. 12 months products warranty.

Why choose us?

1. Over 30 years experience in foundry machinery industry.

2. CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

3. Factory and Competitive Price we offer.

4. Strong Research & Development technical team with more than 36 people of senior professor engineer and senior engineer.

5. Various machinery to meet all your needs at our factory.

6. Prompt and Professional reply regarding our products and service.

7. Hundreds of customers all around the world.