- Product Details

- {{item.text}}

Quick Details

-

Manufacturer:

-

Yes

-

OEM:

-

Accept

-

Brand:

-

STRONG

-

Model:

-

ZY-5KW-STQY

-

Function:

-

Plastic Welding Machine

-

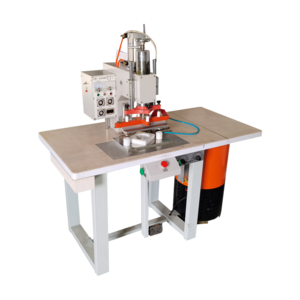

Operation Way:

-

Semi-Automatic

-

ODM:

-

Accept

-

Cetificate:

-

CE Approved

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

500 KG

-

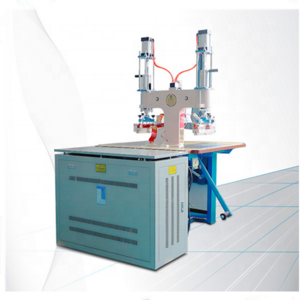

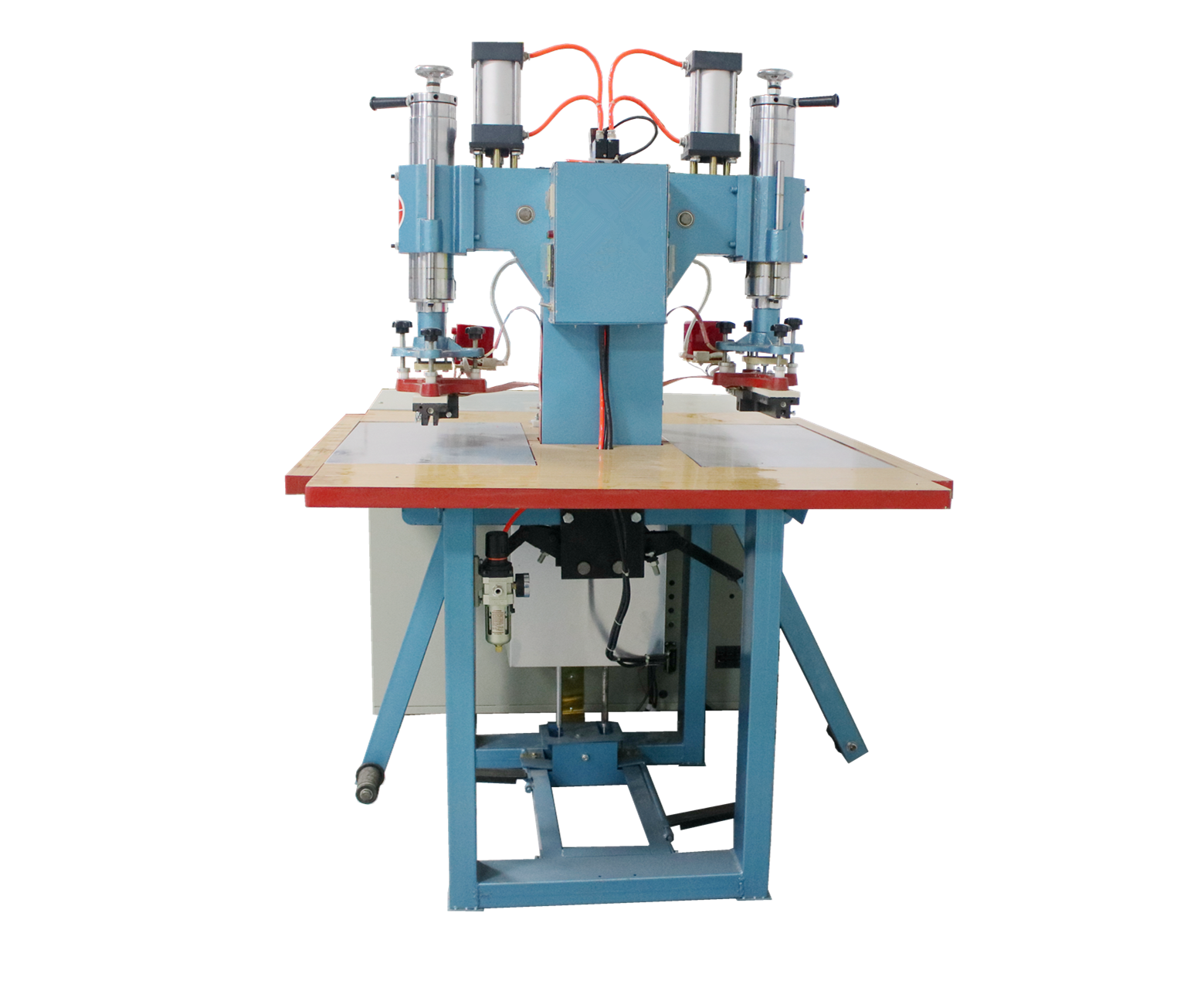

Machine Type:

-

High Frequency Welding Machine

-

Manufacturer:

-

Yes

-

OEM:

-

Accept

-

Brand:

-

STRONG

-

Model:

-

ZY-5KW-STQY

-

Function:

-

Plastic Welding Machine

-

Operation Way:

-

Semi-Automatic

-

ODM:

-

Accept

-

Cetificate:

-

CE Approved

Product Description

Our Advantages

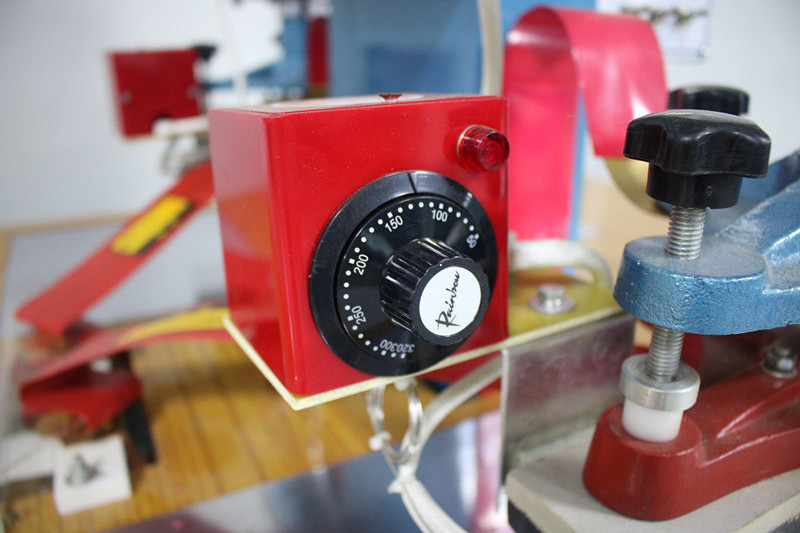

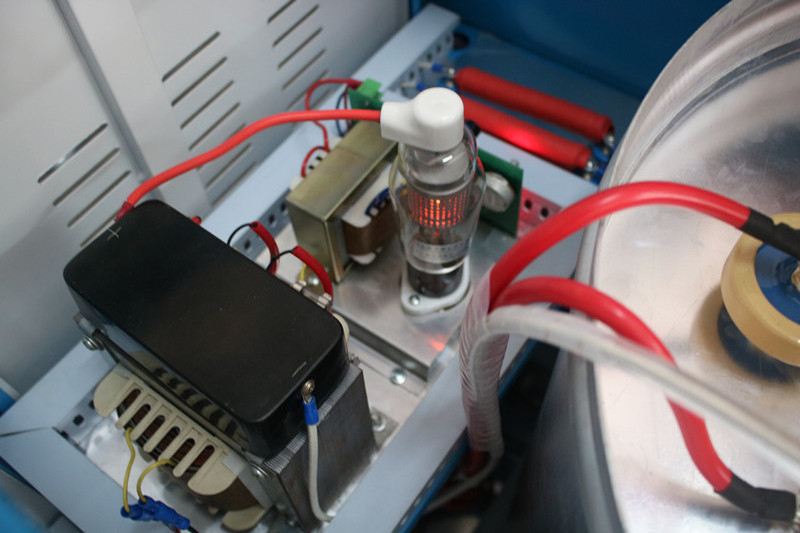

* Safety device- Anti-Spark System

* TOSHIBA(CANON) Oscillation Tube

* Easily Adjustable Tuner

Machine output power can be adjusted at the tuner according to electrode size and material thickness. In addition, other control devices and special electrical circuits have cut down required welding time considerably to raise the machine productivity.

* Heating Controller

*Strong Foot Pedal

Machine using a special designed mechanism, the maximum pressure of foot pedal can reach up to 400KGS so as to meet most operating conditions. The high quality components make these machines work very smoothly and precisely.

*AirTac Air System

Adopting famous brand AirTac air system, greatly make the machine pressure working precisely.

* Jamming Prevention Device

Application

Final products done with HF welding:

Common products manufactured with HF welding method are tarpaulins, tents, ceilings, advertising outdoor banners, waterbeds, inflatable boats, drip and blood bags, tensile structures, conveyor belts, rain clothing, etc.

Machine Parameter

|

Model

|

ZY-5KW-STQY

|

ZY-8KW-STQY

|

|

Output Power

|

5000W

|

8000W

|

|

Voltage

|

380V 3P 50/60Hz

|

380V 3P 50/60Hz

|

|

Input Power

|

8KVA

|

15KVA

|

|

Frequency

|

27.12Mhz

|

27.12Mhz

|

|

Oscillation Tube

|

TOSHIBA 7T85RB

|

TOSHIBA 7T69RB

|

|

Anti-Spark System

|

NL-5557

|

NL-5557

|

|

Max Pressure

|

400KG

|

400KG

|

|

Gap of Eletrode

|

160MM

|

160MM

|

|

Size of Mould Holder

|

160*310MM

|

160*310MM

|

|

Working Table Size

|

350*700MM

|

350*700MM

|

|

Machine Dimension

|

1850*1220*1550MM

|

1850*1220*1550MM

|

|

Machine Net Weight

|

450KG

|

550KG

|

Packing & Delivery

Packing:

Machine packing inside is plastic films and outside is fumigation wooden case.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Delivery:

For machines are big and heavy parcel, and different country with different delivery cost,so we suggest below delivery solution:

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

Hot Searches