- Product Details

- {{item.text}}

Quick Details

-

Working Process:

-

injection, extruding, blow molding,rotational molding, casting

-

Surface treatment:

-

powder coating, polishing, chrome plating

-

Equipments:

-

CNC, EDM, ArgieCharmilles, Milling Machine

-

Product name:

-

plastic injection molding

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

material:

-

ABS, PC, PP, PS, POM, PMMA

-

Working Process:

-

injection, extruding, blow molding,rotational molding, casting

-

Surface treatment:

-

powder coating, polishing, chrome plating

-

Equipments:

-

CNC, EDM, ArgieCharmilles, Milling Machine

-

Product name:

-

plastic injection molding

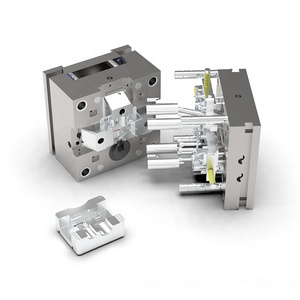

High precision abs plastic moulding custom plastic injection mold for moulding plastic maker

plastic part

1.plastic Injection parts

2.Injection molding with high quality

3.Best design

4.Rich experience

more feature and specifications:

(1)Quality assurance: ISO 9001:2001.

(2)Material:ABS,PP,PC,PBT,PVC,PA6,PA66,TPEE,PC+ABS,etc.

(3)Business Scope:

1.Mold and parts designing.

2.Mould and parts making

3.Parts machining

5.Injection molding

6.CNC prototype manufacturing

(4)Injection parts' surface treatment:Color painting,Texture,Silk-printing, Anodize etc.

(5)ODM&OEM service are all welcomed

(6)Practicable Software:Pro/engineer,Solidworks,UG,Auto cad.

(8)Mold Making Time: 15-35 days

(9)Mold Lift Time: 100000-500000pieces

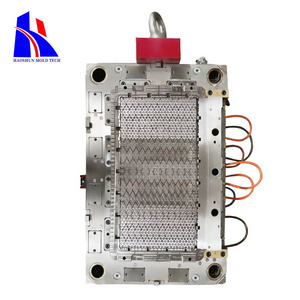

| Item | Description |

| Product Name | Plastic part |

| Working Process | injection, extruding, blow molding,rotational molding, casting,drawing, stamping |

| Material | ABS, PC, PP, PS, POM, PMMA |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Surface treatment | powder coating, polishing, chrome plating |

| Color | Red, blue, green, yellow |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Cavity Number: | Single cavity, Multi Cavity, based on customer' s requirement. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Equipments: | CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machine |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

Packing information for Custom plastic precision injection part.

Port: Ningbo/ Shanghai Port

MOQ: 100 pieces

Supply ability: 18,000,000 pieces/month

Payment terms: T/T,Western Union, Paypal etc.

Packaging: Standard export packing

Delivery time: 15-25 days, depends on quantity

customized plastic part

1.Plastic injection

2.Injection parts

3.Injection molding with high quality

4.Injection products design

5.Rich experience

6.Sample time:15~ 30days.

7.24-hour service with prompt reply