- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Screen Printing Industry

-

Color:

-

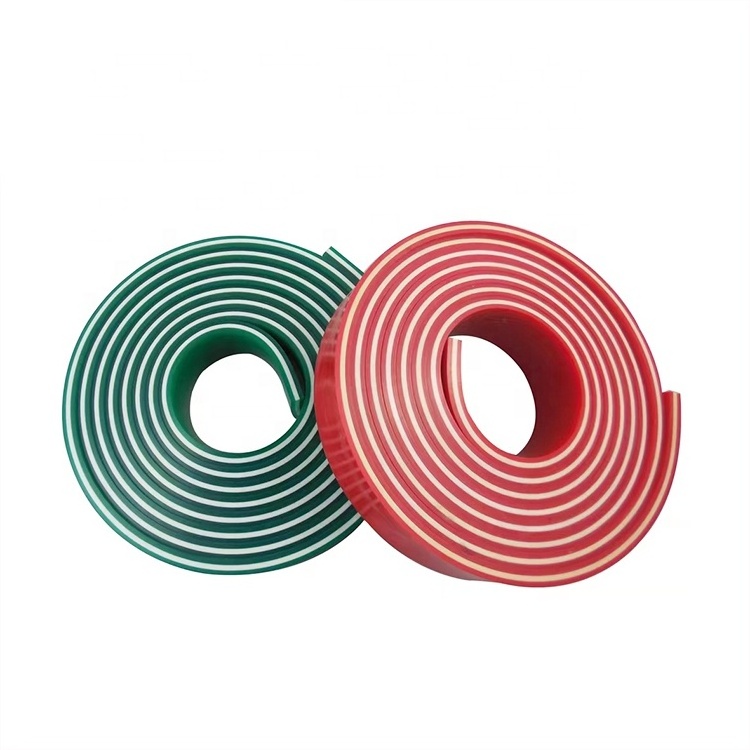

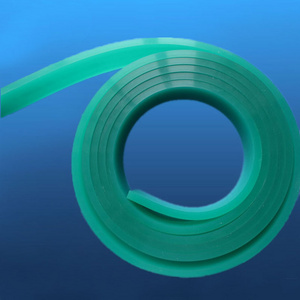

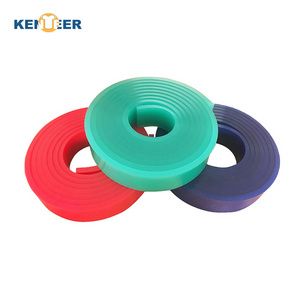

Red. White. Green. Blue

-

Material:

-

Polyurethane

-

Usage:

-

Silk Screen Printing Usage

-

Regular size:

-

50*9*3660 mm

-

Packing:

-

Roll Packed

-

Feature:

-

High Solvent Resistant

-

Hardness:

-

65-95A

-

Delivery:

-

7-10 Working Days

-

MOQ:

-

1 Piece

Quick Details

-

Model Number:

-

PFM-CAM

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

PFM-CAM

-

Application:

-

Screen Printing Industry

-

Color:

-

Red. White. Green. Blue

-

Material:

-

Polyurethane

-

Usage:

-

Silk Screen Printing Usage

-

Regular size:

-

50*9*3660 mm

-

Packing:

-

Roll Packed

-

Feature:

-

High Solvent Resistant

-

Hardness:

-

65-95A

-

Delivery:

-

7-10 Working Days

-

MOQ:

-

1 Piece

Product Description

|

Product Name

|

Silk Screen Printing Squeegee Blade Polyurethane Rubber Screen Printing Squeegee

|

|

Material

|

Polyurethane

|

Squeegees, Screen Printing Tools for Applying Paste/Ink to Mesh Self-Adhesive Reusable Stencils Transfers

The rubber squeegee is one kind of tool that applied the chalk paste or ink on transfer to make it leak to the substrate for DIY hand printing, which has good abrasion resistance and durability, make your printing process easier.

|

Screen Squeegees Rubber

|

|

|

||

|

Hardness

|

Model

|

Color

|

||

|

Soft

|

55,60,65 shore A

|

Red or natural

|

||

|

Medium

|

70,75 shore A

|

Green or natural

|

||

|

Hard

|

80,85 shore A

|

Blue or natural

|

||

|

Super hard

|

90,95 shore A

|

White

|

||

|

Triple medium

|

75/90/75 shore A

|

Green/White/Green

|

||

|

Triple soft

|

65/90/65 shore A

|

Red/White/Red

|

||

|

Standard Size

|

|

|

||

|

Length

|

Width

|

Thickness

|

||

|

≤ 4000 mm

|

9-500 mm

|

2-20 mm

|

||

Standard Profiles

Flat mouth squeegee, commonly used shape, has a certain degree of compliance, and can withstand the highest pressure.

Obtuse-angle squeegee has the characteristics of flat scraping and sharp-angle scraping, and it is not prone to chipping.

The sharp squeegee has good flexibility, compliance, reduces pressure, and is especially suitable for printing on uneven surfaces and irregular shapes.

Instructions:

Try to avoid over-pressing the squeegee on the screen when using it. This will cause the ink layer to be extremely thick, difficult to control, and excessively wear the screen, so the correct way is to make the two ends of the squeegee and the edge of the screen have The appropriate distance, and then use the appropriate pressure to print. When inserting the squeegee into the handle, do not over-press or choose a size that is too thick to forcibly squeeze it in. You should let the squeegee rest on a regular basis instead of continuously using it.

Clean:

Wipe off excess ink with a cloth first, and then use a soft cloth dipped in an appropriate solvent to clean. Do not use strong solvents, especially ink thinners, to clean the squeegee. After grinding or before reuse, the squeegee should be left idle enough to completely volatilize the solvent on it.

Cut into sheets and install on aluminum plates

Customizable length

Usually the effective width of squeegee is between 20MM and 30MM. The selection of the best effective width is based on the flatness of the substrate, the image resolution of the network layout and other printing parameters such as: squeegee Angle, speed and ink type. When printing high resolution images on flat/smooth substrates, the effective width is small (less than 20MM), high hardness, fast printing with suitable ink. In the uneven, rough substrate, the effective width to increase (sometimes greater than 30MM), the hardness is reduced, and the low hardness scraping adaptability is poor, not excessive bending, can also use the middle hard on both sides of the soft three layers of scraping or double scraping. In general, as the effective width increases, the printing speed decreases and the printing Angle increases.

Can be sprayed according to customer requirements

Storage:

1. Store squeezers flat, do not roll into a circle, which may cause permanent bending.

2. The aluminum scraper handle should be placed downward, and the knife edge should not be placed downward.

3. After printing, the squeegee should be cleaned immediately. At this time, it is easy to wash the ink, otherwise it will damage the knife edge to wipe off the dry ink.

4. Do not soak the squeegee in the solvent. Although the squeegee is solvent resistant, the squeegee will absorb solvent and become brittle.

5. The squeegee is still soft and the solvent is not completely volatile after cleaning, so it cannot be polished immediately. After 12 to 24 hours of "recuperation" can be used again. This can not only improve the grinding effect but also improve the printing effect.

6. According to the specific printing quality requirements, the glue scraping should be polished often. When cleaning and polishing, the loss of glue scraping should be reduced as much as possible.

Packing & Delivery

Box + Carton

Silk Screen Printing Squeegee Blade Polyurethane Rubber Screen Printing Squeegee

Transportation&Payment

Our Customers

Hot Searches