- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/480V/600V

-

Dimension(L*W*H):

-

as per model

-

Weight:

-

600 KG

-

Product name:

-

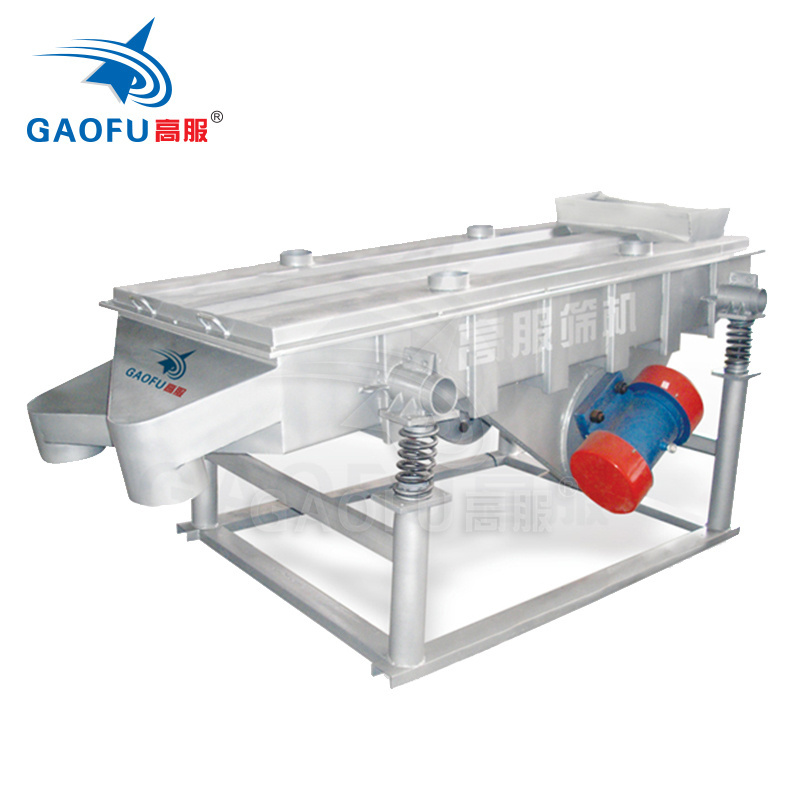

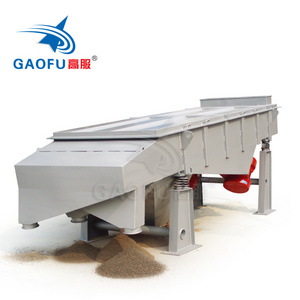

Linear Vibrating Screen

-

Material:

-

Carbon Steel

-

Motor:

-

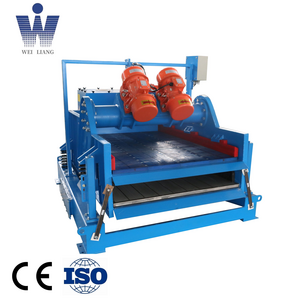

Two Vibration Motor

-

Usage:

-

Separation\Screening

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

10Kg-20 tons/hour

-

Screen mesh size:

-

2-500 mesh

-

Cleaning system:

-

Bouncing Ball

-

Applicable Material:

-

Powder\Granules

-

Advantage:

-

High Output

Quick Details

-

Type:

-

LINEAR

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gaofu

-

Voltage:

-

220V/380V/415V/480V/600V

-

Dimension(L*W*H):

-

as per model

-

Weight:

-

600 KG

-

Product name:

-

Linear Vibrating Screen

-

Material:

-

Carbon Steel

-

Motor:

-

Two Vibration Motor

-

Usage:

-

Separation\Screening

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

10Kg-20 tons/hour

-

Screen mesh size:

-

2-500 mesh

-

Cleaning system:

-

Bouncing Ball

-

Applicable Material:

-

Powder\Granules

-

Advantage:

-

High Output

Our strength

20 designers technical team,

10 production line ,

30,000 sets per year

60,000+m² cover area

Fine Quality

ISO9001, ,CE,TUV,BV ,SGS certificated.

Fine feedback from customer.

Superior Service

|

Model

|

Size

(mm)

|

Granularity(mm)

|

Leanangle

(°)

|

Amplitude (mm)

|

Layers

|

Power

(kw)

|

|

SZF-520

|

500X2000

|

|

0°-7°

|

4-10

|

1-6

|

2x(0.4-0.75)

|

|

SZF-525

|

500X2500

|

|

|

|

|

2x(0.4-0.75)

|

|

SZF-1020

|

1000X2000

|

|

|

|

|

2x(0.4-0.75)

|

|

SZF-1025

|

1000X2500

|

|

|

|

|

2x(0.4-1.1)

|

|

SZF-1030

|

1000X3000

|

|

|

|

|

2x(1.1-1.5)

|

|

SZF-1040

|

1000X4000

|

|

|

|

|

2x(1.1-1.5)

|

|

SZF-1235

|

1200X3500

|

|

|

|

|

2x(1.1-2.2)

|

|

SZF-1250

|

1200X5000

|

|

|

|

|

2x(1.1-2.2)

|

|

SZF-1535

|

1500X3500

|

|

|

|

|

2x(1.1-2.2)

|

|

SZF-1565

|

1500X6500

|

|

|

|

|

2x(2.2-3.7)

|

|

SZF-1845

|

1800X4500

|

0.074-15

|

|

|

|

2x(2.2-3.7)

|

|

SZF-2050

|

2000X5000

|

|

|

|

|

2x(2.2-3.7)

|

|

SZF-2260

|

2200X6000

|

|

|

|

|

2x(2.2-3.7)

|

S

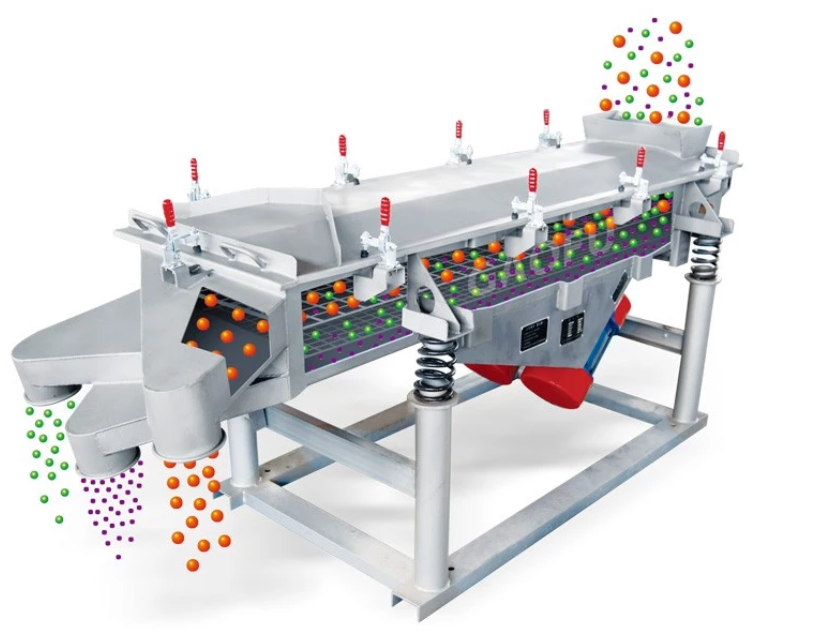

ZF

series linear sieve separating machine use vibration motor as vibration source, the material is rosed and moved in the straight at the same time. The material are entered into entrance equality, and then go through screen to create the materials with different sizes, which was discharged, from different gates. It is suitable for low consuming, high output, and simple structure, easily maintain all-closed structure, no powder dispersed.

The two motor of the machine do relative work, so that the material on the surface do jumping movement, material less than the mesh hole will fall to the lower deck ,and discharged after continuous jump.Because of the screening process is reasonable ,the materials after classification can obtain serveral different particle size,then the classification work is finished .