- Product Details

- {{item.text}}

Quick Details

-

name:

-

press felt

-

Color:

-

white , yellow and you required

-

Application:

-

paper mill used press felt

-

Air permeability:

-

20-140 cfm

-

Paper machine:

-

kinds of paper machine

-

experience:

-

since the year of 1980

-

main feature:

-

long service life

-

using part:

-

paper machine press part

-

Linear pressure:

-

100-200kN/m

-

Keyword:

-

paper mill felt

Quick Details

-

Weight (KG):

-

30

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

name:

-

press felt

-

Color:

-

white , yellow and you required

-

Application:

-

paper mill used press felt

-

Air permeability:

-

20-140 cfm

-

Paper machine:

-

kinds of paper machine

-

experience:

-

since the year of 1980

-

main feature:

-

long service life

-

using part:

-

paper machine press part

-

Linear pressure:

-

100-200kN/m

-

Keyword:

-

paper mill felt

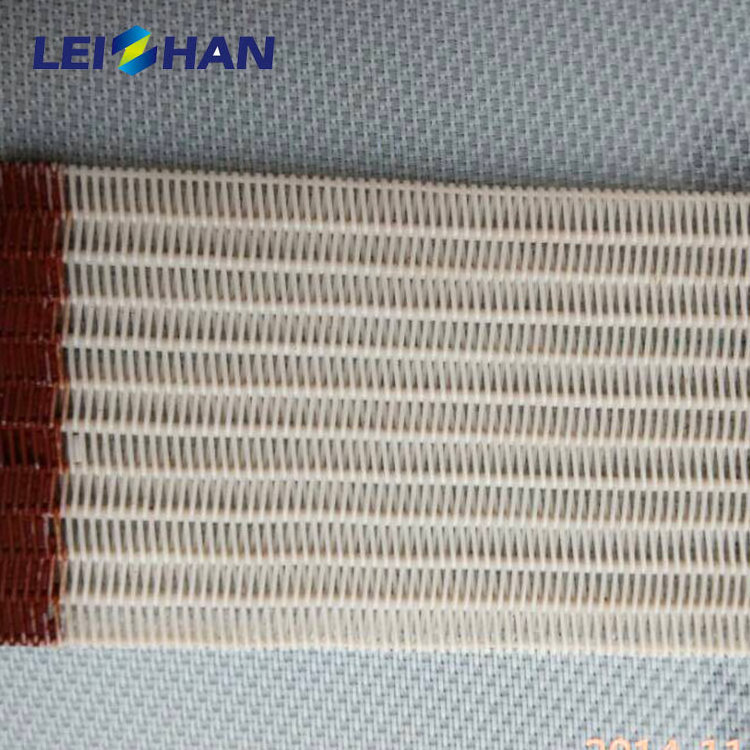

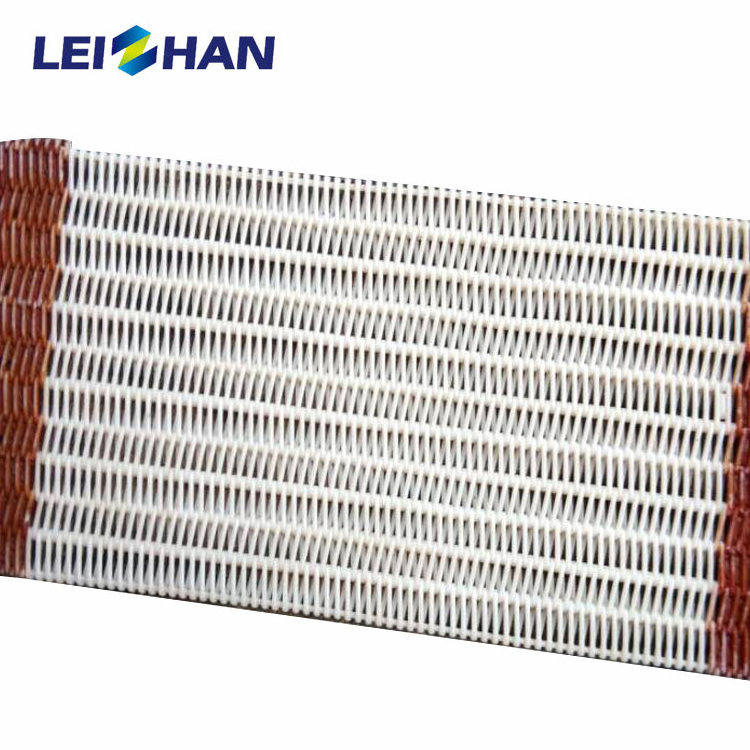

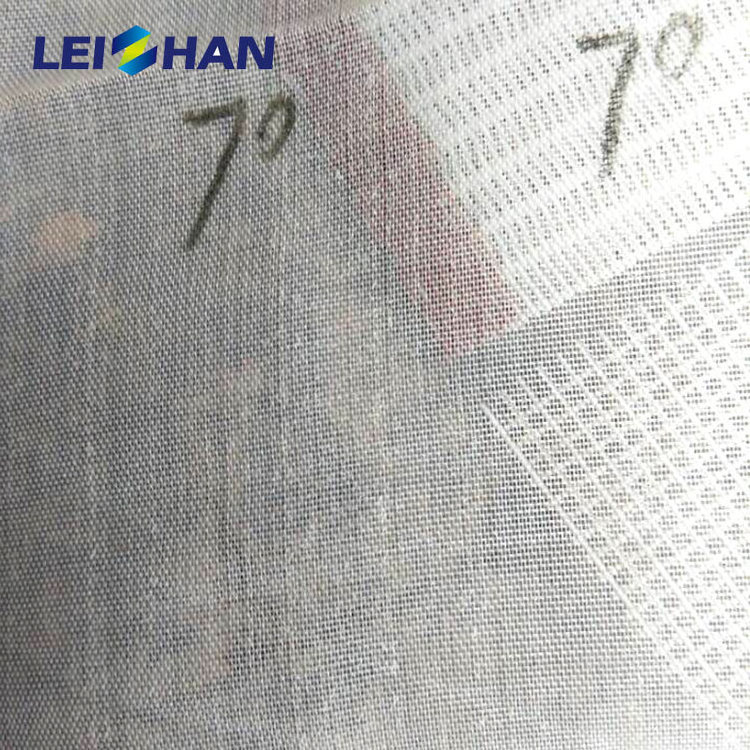

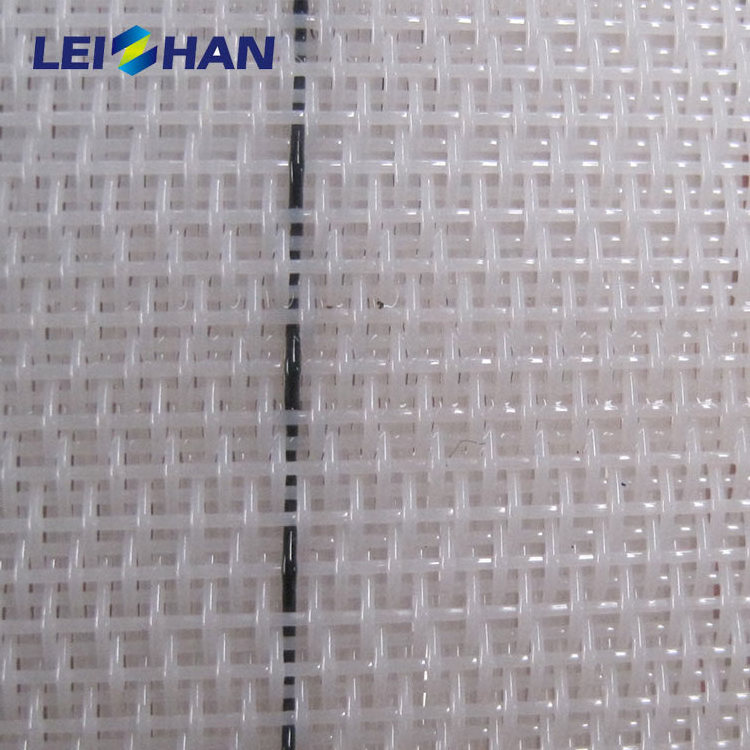

Paper Mill Cloth Production Line Forming Fabric Press Felt For Paper Making

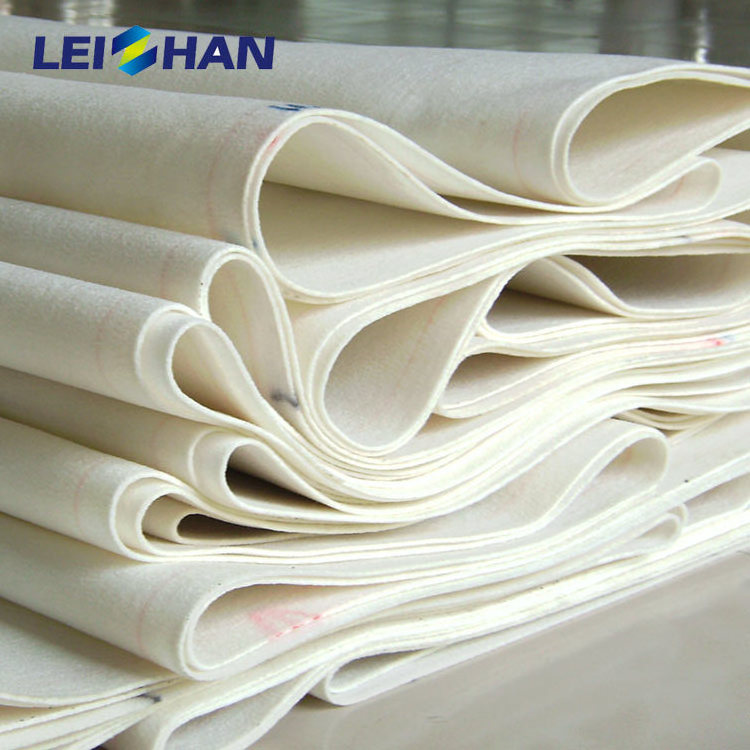

Introduction of paper mill felt

China product paper mill felt, press felt in paper machinery part is a nessesarry spare part of paper machine in forming and pressing sections.In the forming part, it is the felt that form paper pulp to paper sheets. In the press section, paper machine felt is also used with felt rolls.

Application:

1.Apply to improved cylinder vatmachines: 200 - 300m/min

2.Apply to Imitation BF and Imitation crescent formermachines: 250 – 600m/min

3.Apply to Imitation BF Series and crescent formermachines: 700-900m/min

Feature:

1. High anti-compaction capacity.

2. Extremely high elasticity and recoverability.

3. Strong drainability abd larger void volumn.

4. Long holding time of wear resistance and plastic strength of felt.

5. Smooth felt surface and even pressure distribution.

Technical merits of felt in paper machine

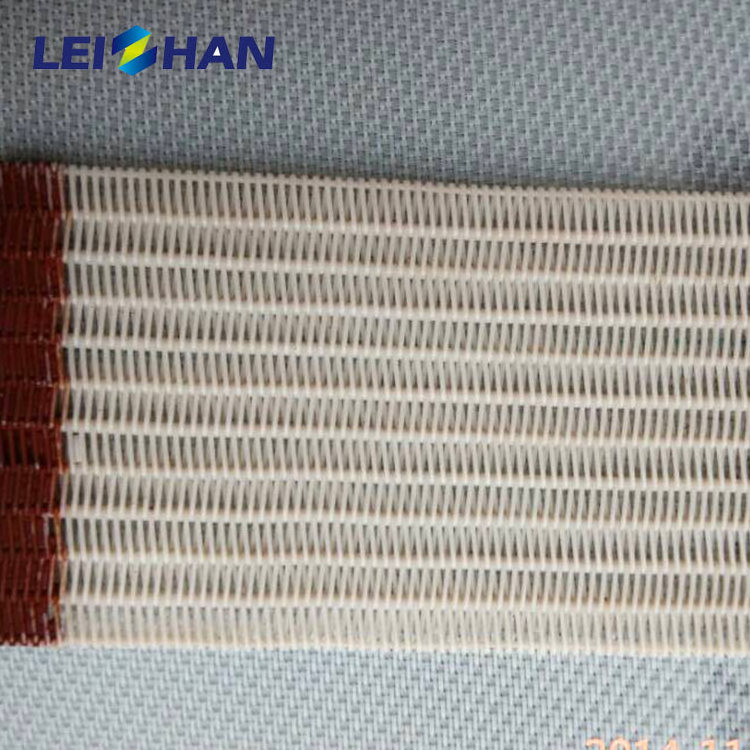

Weaving: endless weaving

Fabrics: all imported fiber, high-smoothness, making the paper superfine

Property: high start-up speed, good stability, short delivery time

Finishing: washing, pre-compaction, singeing

Specifications:

| GSM | Structure style | Application | Note |

| 950—1300 | Double layer domestic material | Corrugating, kraft paper,package paper | Excellent tensile strength, good filtration, good adsorbability, dimension atability, long life performance |

| 1000—1100 | Double layer domestic material | Corrugating, kraft paper,package paper | Excellent tension strength, good filtration, good ability to absorb, dimension stability, long life performance |

| 900—1100 | Double layer domestic material | Corrugating, kraft paper,package paper | Excellent tensile strength, good filtration, good ability adsorbability, long life performance dimension stability |

| 1100—1400 | Double layer domestic material | Write paper, printing paper, newspaper,package paper, kraft paper |

Lighten trace, high line press resistance,

long life performance |

| 950—1300 | Double layer import material |

Corrugating, kraft paper,

package paper |

Excellent tensile strength, good filtration, anti-abrasion, long life performance, dimension stability |

| 1000—1100 | Double layer import material | Kraft paper, paper board | Excellent tensile strength, good filtration, long life performance, anti-abrasion dimension stability |

| 1200—1500 | Double layer import material | Write paper, printing paper, newspaper,package paper, kraft paper | Lighten trace, high line press resistance, good filtration, dimension stability, long life performance |

| 900—1100 | Double layer import material | Corrugating, kraft paper, package paper | Excellent tension strength, good filtration, long life performance, dimension stability |

| 1200—1500 | Double layer import material | Big roll press for high-grade, package paper, paper borad | Lighten trace, high line press resistance, good filtration, dimension stability, long life performance |

Paper mill machine:

1.Pre-sales Service

- Proposing the most suitable scheme and equipment for our clients.

- Designing and fabricating targeted products according to the special requirements of clients.

- Training periodically high qualified service technician.

2.After-sales Service

- Assisting our clients for foundation construction of equipment.

- Dispatching engineers to install and debug equipment.

- Training the first-line operators on site.

- Regularly visit clients to solve production problems.