- Product Details

- {{item.text}}

Quick Details

-

Structure:

-

Control

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Better

-

Model Number:

-

BT_01

-

Port Size:

-

customize

-

Product name:

-

Silicone Valve

-

Material:

-

Food Grade Silicone

-

Color:

-

Any color you need

-

Certification:

-

Certificate

-

Size:

-

Accept Customization

-

Item:

-

Molded Rubber Parts

-

Usage:

-

one way check valve

-

Package:

-

PP Bags

Quick Details

-

Type:

-

Drain Valves, Air Valves & Vents

-

Application:

-

General

-

Power:

-

Hydraulic

-

Structure:

-

Control

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Better

-

Model Number:

-

BT_01

-

Port Size:

-

customize

-

Product name:

-

Silicone Valve

-

Material:

-

Food Grade Silicone

-

Color:

-

Any color you need

-

Certification:

-

Certificate

-

Size:

-

Accept Customization

-

Item:

-

Molded Rubber Parts

-

Usage:

-

one way check valve

-

Package:

-

PP Bags

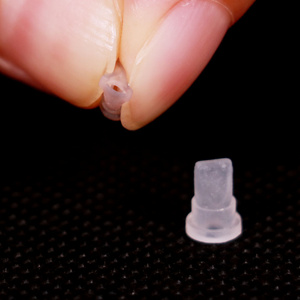

FDA Silicone Cross-slit Check Valve

Silicone valves, also known as One way valves, non-return valves, air flow valves, rubber check valves, which are used for controlling the direction of fluids' flow. Our silicone valves can be universally applied in many different applications, whether in the health care, automotive, appliance or food and packaging industries. Silicone valves include umbrella valves, duckbill valves, membrane valves, flapper valves and diaphragm valves, etc.

How to Control the pressure of Cross Slit Valve:

As we know, the materil, hardness and diameter will effect the pressure value of the valve. But most important is the structure of the valve itself. How to make sure we can provide the one that customers want? We will try to test different thickness for customers. As we can see the picture, there three different thickness valves. The rectangular is the side thickness of the valves and the circle one is the opening thickness(flap thickness) of the valves. Both of these thickness will lead to different pressure values. We have test 3 different thickness, and 4 different hardness for our customer, and our customer can choose the one match their requirements easily.

How we ensure quality

Hardness Test, Appearance Inspection, Dimension Test, Air Pressure Test.

|

Material

|

Temperature Range

|

Aging Weathering

|

Oil Resistance

|

Water Swell Resistance

|

Flex-Fatigue

|

Economy of Material

|

|

CR

|

-40F to 250F

|

Good

|

Good

|

Average

|

Very Good

|

Good

|

|

NBR

|

-22F to 212F

|

Poor

|

Very Good

|

Good

|

Good

|

Very Good

|

|

EPDM

|

-60F to 300F

|

Very Good

|

Poor

|

Very Good

|

Good

|

Very Good

|

|

Silicone

|

-75F to 450F

|

Very Good

|

Average

|

Very Good

|

Very Good

|

Average

|

|

FKM

|

5F to 390F

|

Very Good

|

Very Good

|

Good

|

Average

|

Poor

|

Medical Plastic/LSR Products

Except for silicone valves, our factory-Xiamen Better Silicone Rubber Co.,Ltd is specialized in making other silicone rubber compression molding & plastic injection molding & LSR injection molding, and produce silicone, rubber, plastic and liquid silicone rubber parts and products according to 2D&3D design drawings, samples since 1998 years.

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters

.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, etc.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.