The feeding rollers which we use is stainless steel.

And the ball bearing roller is inside the feeding rollers which is very convenient to feed the steel coil into it.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

7800*800*1200mm

-

Weight:

-

3600 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

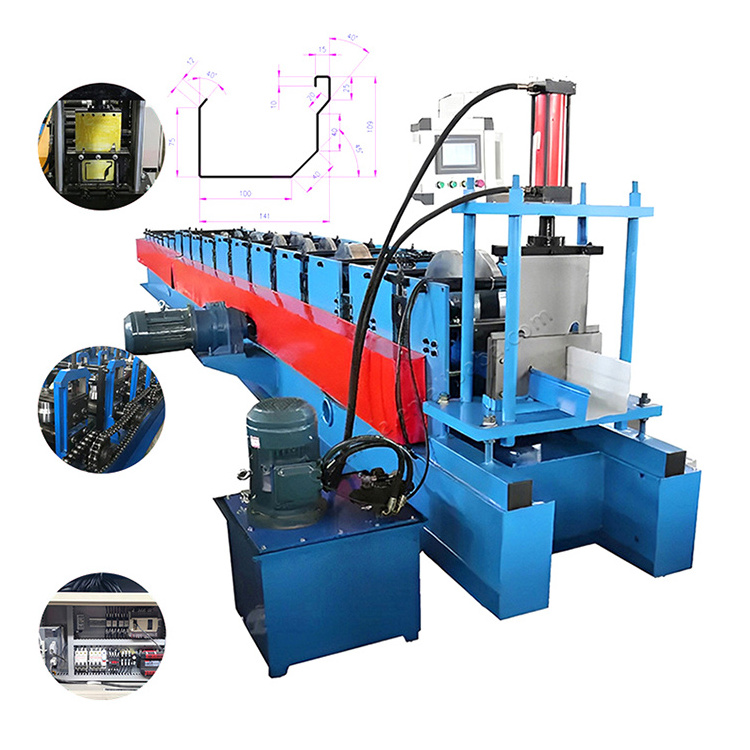

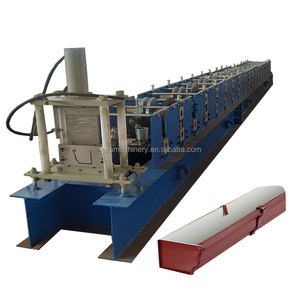

Downspout Roll Forming Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Roller material

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Roll Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-20 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

7800*800*1200mm

-

Weight:

-

3600 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

Downspout Roll Forming Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

Roller material

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Usage:

-

Galvanize roof sheets machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Products Description

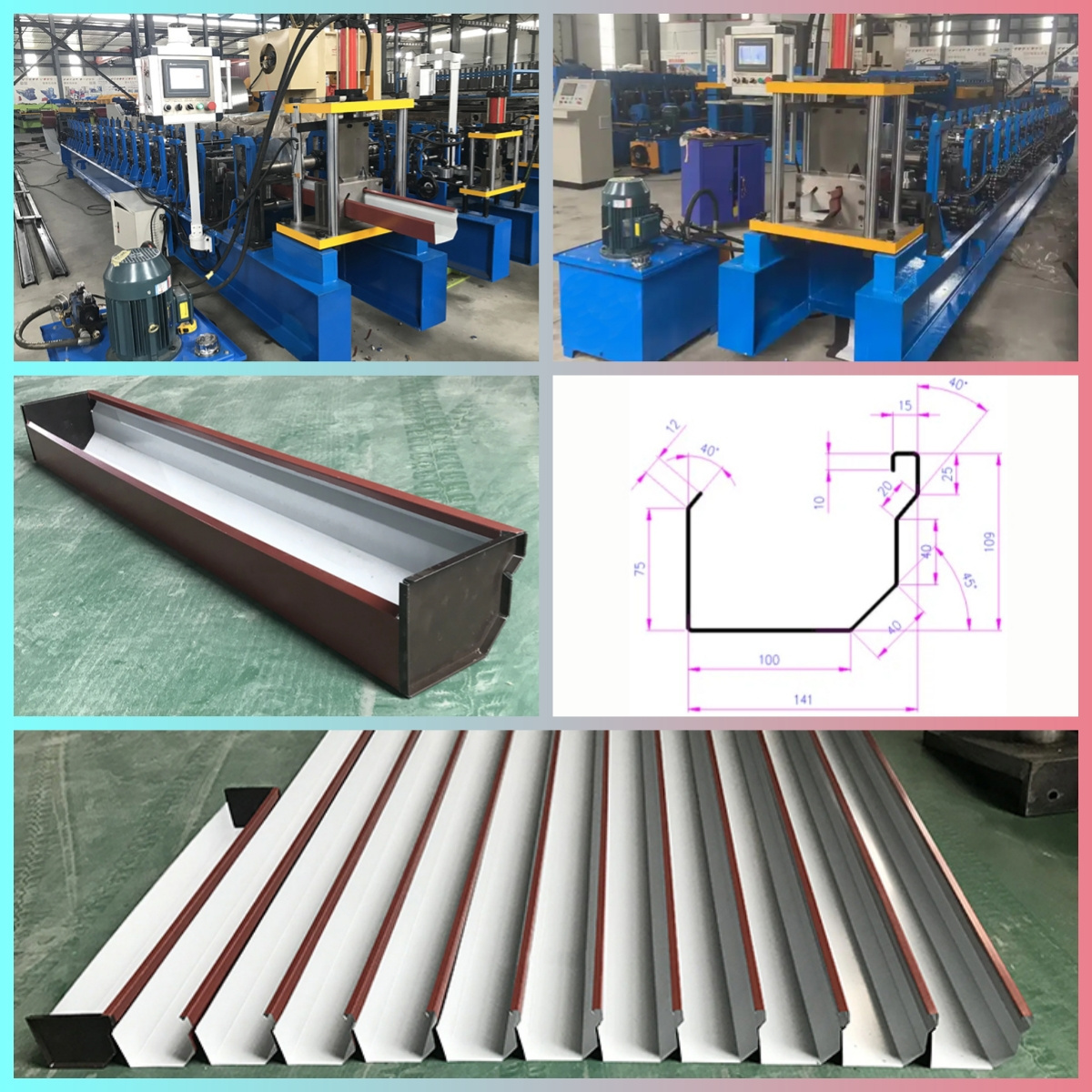

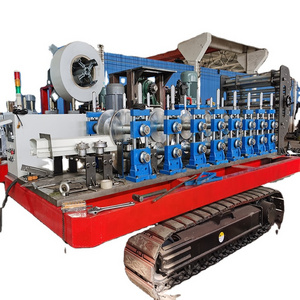

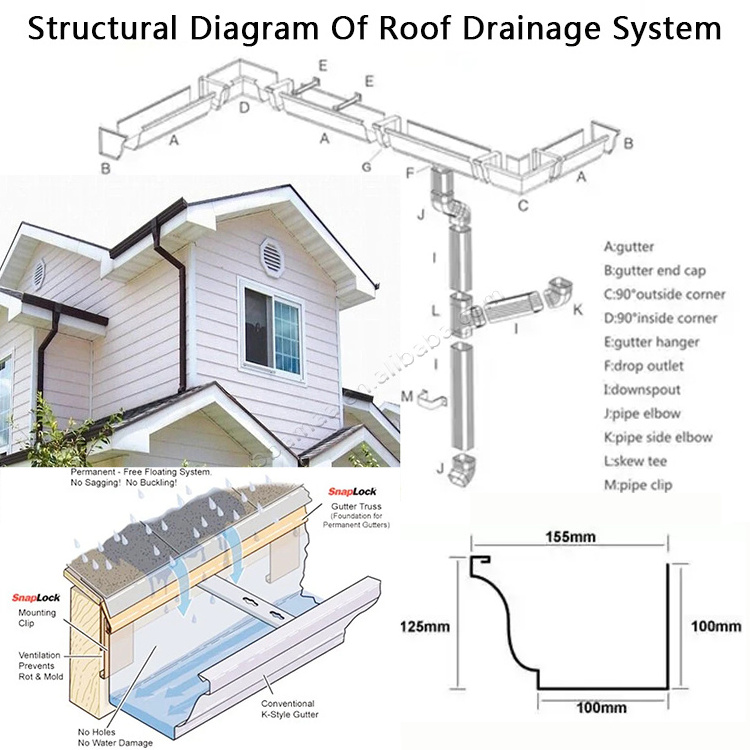

Metal Rain Gutter Roll Forming Machine

Metal Rain Gutter Roll Forming Machine is mainly used to produce Rain gutter applied to construction. Fully automatic production is more efficient and helps save manpower and material resources. The produced rolling shutter door occupies a small space,durable, not easy to be damaged or rusted, and is convenient to retract.

Work processing

Processing Flow

Manual decoiler→Feeding material →roll forming→strengthening→Hydraulic cutting→product receiving table

Specification

|

Metal Rain Gutter Roll Forming Machine

|

|

|

||

|

SN

|

Item

|

Specification

|

||

|

1

|

Suitable to process

|

Color alu-zinc steel coil

|

||

|

2

|

Roller

|

16-18Rows

|

||

|

3

|

Dimensions

|

7800*800*1200mm

|

||

|

4

|

Motor Power

|

5.5Kw

|

||

|

5

|

Pump Station Motor

|

4Kw

|

||

|

6

|

Thickness of the plate

|

0.3-0.8mm

|

||

|

7

|

Productivity

|

10-20m/min

|

||

|

8

|

Material of the cutting blade

|

Cr12,Quenched treatment 58℃-60℃

|

||

|

9

|

Diameter of the roller

|

Φ70mm

|

||

|

10

|

Weight

|

About 3600kgs

|

||

|

11

|

Main structure of the machine

|

350H beams

|

||

|

12

|

Chain Wheel and Cycle Chain

|

1 Inch

|

||

|

13

|

Voltage

|

380V 50Hz 3phases or as customer's need

|

||

|

14

|

Control system

|

PLC control

|

||

|

15

|

Rolling materials

|

45# forging steel with chromium plate

|

||

Product Details

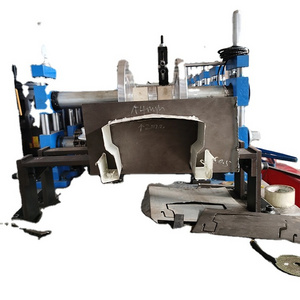

Feeding Device

Roll Forming Device

1. Base Frame Structure: 350 H-beam welded.

2. Connect Bar: Diameter 25mm galvanized steel rod.

3. Forming speed: 10-20m/min.

4. Feature: Ensure stability , precision and lifetime.

3. Forming speed: 10-20m/min.

4. Feature: Ensure stability , precision and lifetime.

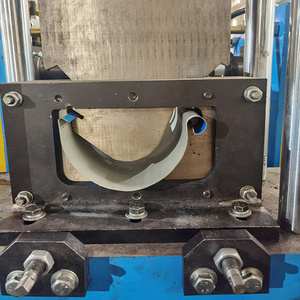

Gear and chain transmission device

1.Controlled by oil pump.

2.Automatic cutting as target products length Blade material: Cr12, quenching treatment.

3.Hardness:

50-65 HRC.

4.Cutting tolerance:

± 1 mm.

Hydraulic Cutting Device

1. Frame Structure: Steel plate welded and screwed.

2. Platform Function: easily to pre-cut the plate while change different steel coils.

3. Cutting Blade: Cr12Mov.

3. Cutting Blade: Cr12Mov.

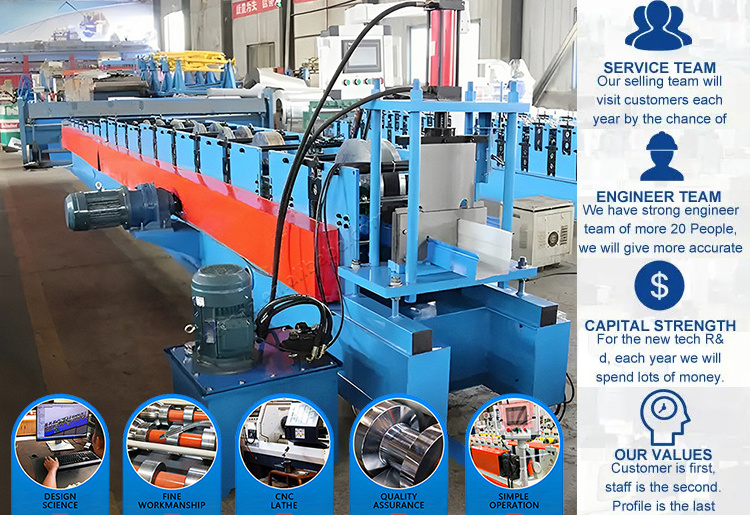

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

Glazed Type

Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce .

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You did not display the product I need. Can you produce it?

Our engineers have studied at well-known European companies and have significant advantages in mechanical design, research and development, and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Hot Searches