- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

12000 kg

-

Name:

-

Rendering Machine Fish Meal Machine Animal Waste Rendering Plant

-

Function:

-

waste to feedstuff

-

Capacity:

-

2mt/day

-

Product name:

-

Animal Feed Processing Plant

-

Material:

-

Stainless Steel Frame Structure

-

Raw material:

-

Fish, shrimp waste

-

Design temp:

-

130-150℃

-

Design pressure:

-

0.5-0.75Mpa

-

Advantage:

-

High Efficient

-

Color:

-

Customized Color

Quick Details

-

Max. Capacity:

-

5 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sensitar

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

12000 kg

-

Name:

-

Rendering Machine Fish Meal Machine Animal Waste Rendering Plant

-

Function:

-

waste to feedstuff

-

Capacity:

-

2mt/day

-

Product name:

-

Animal Feed Processing Plant

-

Material:

-

Stainless Steel Frame Structure

-

Raw material:

-

Fish, shrimp waste

-

Design temp:

-

130-150℃

-

Design pressure:

-

0.5-0.75Mpa

-

Advantage:

-

High Efficient

-

Color:

-

Customized Color

Products Description

The fish meal processing line mainly consists of a cooker, a press, a dryer, a cooler and a hammer mill etc.It is a modern design with easy operation, low energy consumption, low maintenance and long work life. The finished products are high quality fish meal and oil.

Technological proces

Simple process introduction

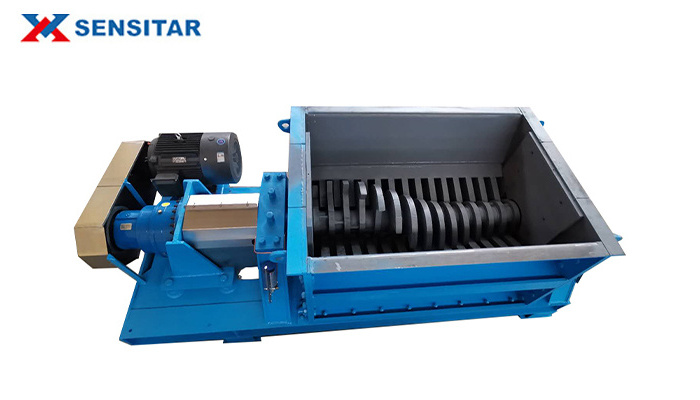

The raw fish or fish steaks and waste are fed into crusher, and then continuously fed into the cooker by a conveyor.After the material is cooked, it is directly put into the press to get meal cake and oil. Meal cake goes into the dryer to dry.

Sizing

The pre-breaker is installed as the first stage of a fish meal plant , All knives and anvils are hard faced .Low operation costs are assured.The motor size and breaker shaft speed can be adjusted to the required capacity.

Pressing

Large capacity , occupy a small workshop area .Low power consumption , easy operation , management and maintenance. Low residual oil press cake , good oil quality , the processed cake is loose and not fragile .

Cooking&heating

The cooker is to cook fish via high temperature..It’s a main machine of the whole line.The indirect cooker are applied in processes where high yield from raw material of variable quality and composition is required .

|

Cooker Type

|

Capacity(t/h)

|

length(mm)

|

Height(mm)

|

Width(mm)

|

Weight(metric ton)

|

|

XFC0605

|

2.6-3.5

|

3350

|

1050

|

1200

|

4

|

|

XFC0806

|

6.4-8.0

|

8250

|

1850

|

1850

|

12

|

|

XFC0808

|

8.8-11.0

|

10200

|

1850

|

1850

|

14

|

|

XFC1108

|

12.8-16.0

|

10900

|

2350

|

2200

|

20

|

|

XFC1110

|

16.0-20.0

|

12800

|

2350

|

2200

|

23

|

|

XFC1112

|

20.0-25.0

|

14850

|

2350

|

2200

|

27

|

|

XFC1310

|

20.0-25.0

|

13050

|

2450

|

2200

|

32

|

|

XFC1312

|

24.0-30.0

|

15050

|

2450

|

2200

|

36

|

|

XFC1314

|

28.0-35.0

|

17050

|

2450

|

2200

|

40

|

|

XFC1612

|

30.4-38.0

|

15150

|

3450

|

2400

|

40

|

|

XFC1614

|

35.2-44.0

|

17150

|

3450

|

2400

|

47

|

|

XFC1616

|

40.0-50.0

|

19150

|

3450

|

2400

|

55

|

Other equipment

Cooler Decanter Air condenser

Application

Whole fish(different kinds of fresh fish, fish heads, fish sausages and offals,fish waste),food waste, other aquatic products,like shrimp,loach,etc

Packing & Logistic

Package: standard package for sea

We usually pack our products by standard sea package. We always choose the best and safe packaging material to make sure your product won't be damaged during delivery.

We usually pack our products by standard sea package. We always choose the best and safe packaging material to make sure your product won't be damaged during delivery.

Company Introduction

Sensitar is a comprehensive research and development machinery manufacturer of fish meal and animal feed machine, with government A2 pressure vessel, owns a modern factory with over 20000 square meters, have 16 professional senior engineers, one UK technical adviser. Absorbing advanced technologies from Denmark, the company has gained thirteen patents. Meanwhile, the company has passed ISO certificate, CE certificate, ASME certificate, SGS certificate.We establish a long-term cooperation relation with companies of South Korea, USA, Germany, Russia, Thailand, Malaysia, Philippines etc.

Our company also produces food processing machine and pressure vessel,inculding Sterilization autoclave,Jacketed pot,Vacuum cooling machine,Vulcanization tank,Autoclave,wood processing machine etc.

Our Customer

Certificate

FAQ

Q:What are the payment terms?

A:T/T,L/C and trade assurance are acceptable,T/T will be more appreciated,30% deposit before production,70% balance before shipment.

Q:What is the delivery time?

At least 2 month after the deposit for most machines

Q:How to pack the machine?

A;Standard packaging

Q:How to install after the machines arriving destination?

A:Our engineer will go to customers site if you need,but need to pay installation fee according to the contract.

Q:What's the capacity you can do?

A:We always produce any capacity depend on customer needs

A:T/T,L/C and trade assurance are acceptable,T/T will be more appreciated,30% deposit before production,70% balance before shipment.

Q:What is the delivery time?

At least 2 month after the deposit for most machines

Q:How to pack the machine?

A;Standard packaging

Q:How to install after the machines arriving destination?

A:Our engineer will go to customers site if you need,but need to pay installation fee according to the contract.

Q:What's the capacity you can do?

A:We always produce any capacity depend on customer needs

Name Card

Name: Jerry Jiang

E-mail: jerry@xzdjx.com

Tel: +86-18766363705

Add: Xiangzhou Industrial Park, Zhucheng City, Shandong Province

Branch add: Xinjunhuan Rd, Minhang District, Shanghai

www.sensitar.com

Tel: +86-18766363705

Add: Xiangzhou Industrial Park, Zhucheng City, Shandong Province

Branch add: Xinjunhuan Rd, Minhang District, Shanghai

www.sensitar.com

* Recruit global agents and distributors

Hot Searches