Bottle Type: Bottles , Cans

Bottle Volume: 100-2500ml

Production Speed: 1000-32000bph

Bottle Size:

Height 170-320

Diameter 20-100

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+/-1MM

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PAIMA

-

Weight:

-

2500 KG

-

Control:

-

PLC+ Touch Screen

-

Capacity:

-

2000-24000BPH

-

Usage:

-

water, Carbonated soft drink,CSD,juice,etc

-

Feature:

-

High Precision Filling Level

-

Filling range:

-

100ml-5000ml

-

Function:

-

Bottle Washing Filling Capping

-

Machine type:

-

One Automatic Liquid Filling

-

Suitable bottle:

-

plastic glass round square bottle

-

Machine material:

-

Stainless Steel SUS 304/316

-

Bottle Shape:

-

Square Round Curve Ellipse Customized

-

Marketing Type:

-

New Product 2022

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Juice

-

Filling Accuracy:

-

+/-1MM

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PAIMA

-

Weight:

-

2500 KG

-

Control:

-

PLC+ Touch Screen

-

Capacity:

-

2000-24000BPH

-

Usage:

-

water, Carbonated soft drink,CSD,juice,etc

-

Feature:

-

High Precision Filling Level

-

Filling range:

-

100ml-5000ml

-

Function:

-

Bottle Washing Filling Capping

-

Machine type:

-

One Automatic Liquid Filling

-

Suitable bottle:

-

plastic glass round square bottle

-

Machine material:

-

Stainless Steel SUS 304/316

-

Bottle Shape:

-

Square Round Curve Ellipse Customized

-

Marketing Type:

-

New Product 2022

Product Description

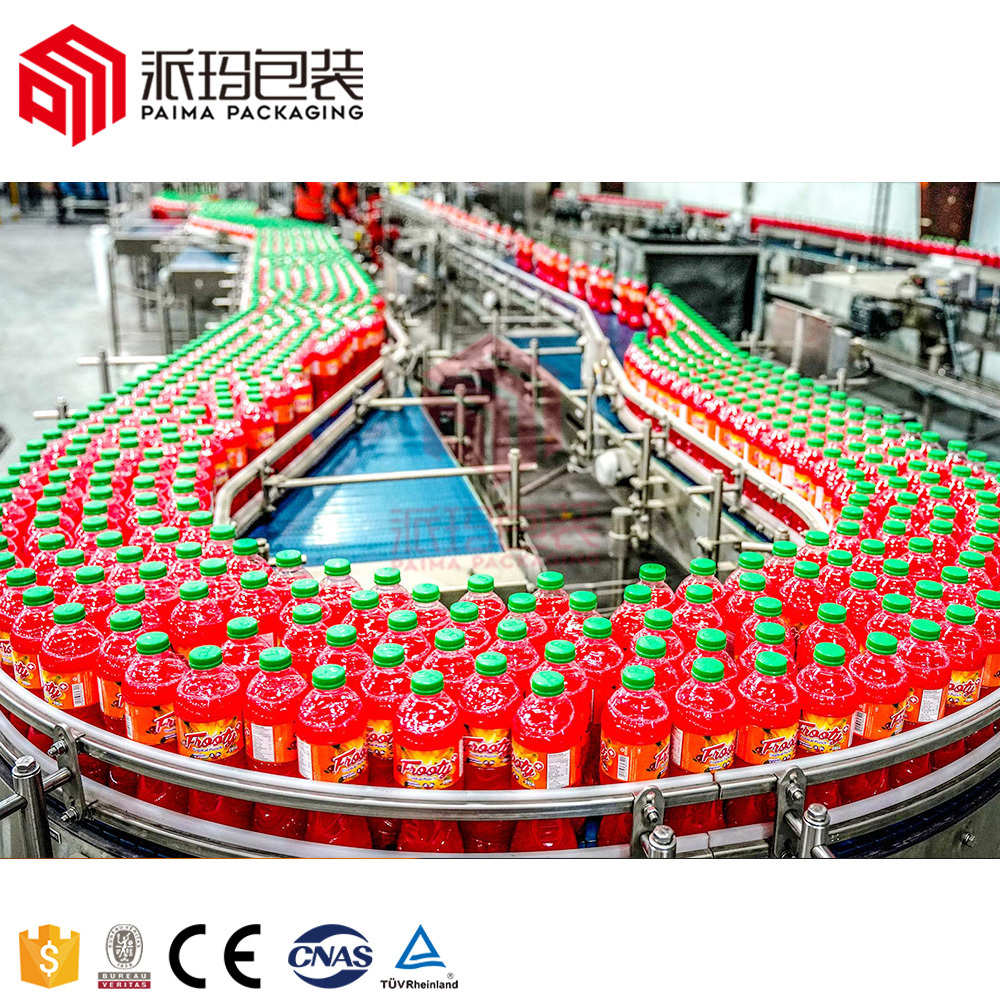

Introductions of soda drink filling machines

This type of machine is suitable for filling and sealing aluminum canned beer and carbonated soft drinks. It is equipped the advanced device,

electrical equipment, and pneumatic control technology. It has the characteristics of filling repose fully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system.

It is the preferred equipment for the medium beer and beverage plant.

And we are able to provide the complete pop cans / tin can filling and package solution, from can depalletizer, can rinsing

machine, can filling & sealing monoblock machine, leakage check, liquid nitrogen dosing machine, pasteurizer tunnel, blow dryer,

carton package, film package system ,which is widely used for the beverage, beer, juice industry and so on.

Features

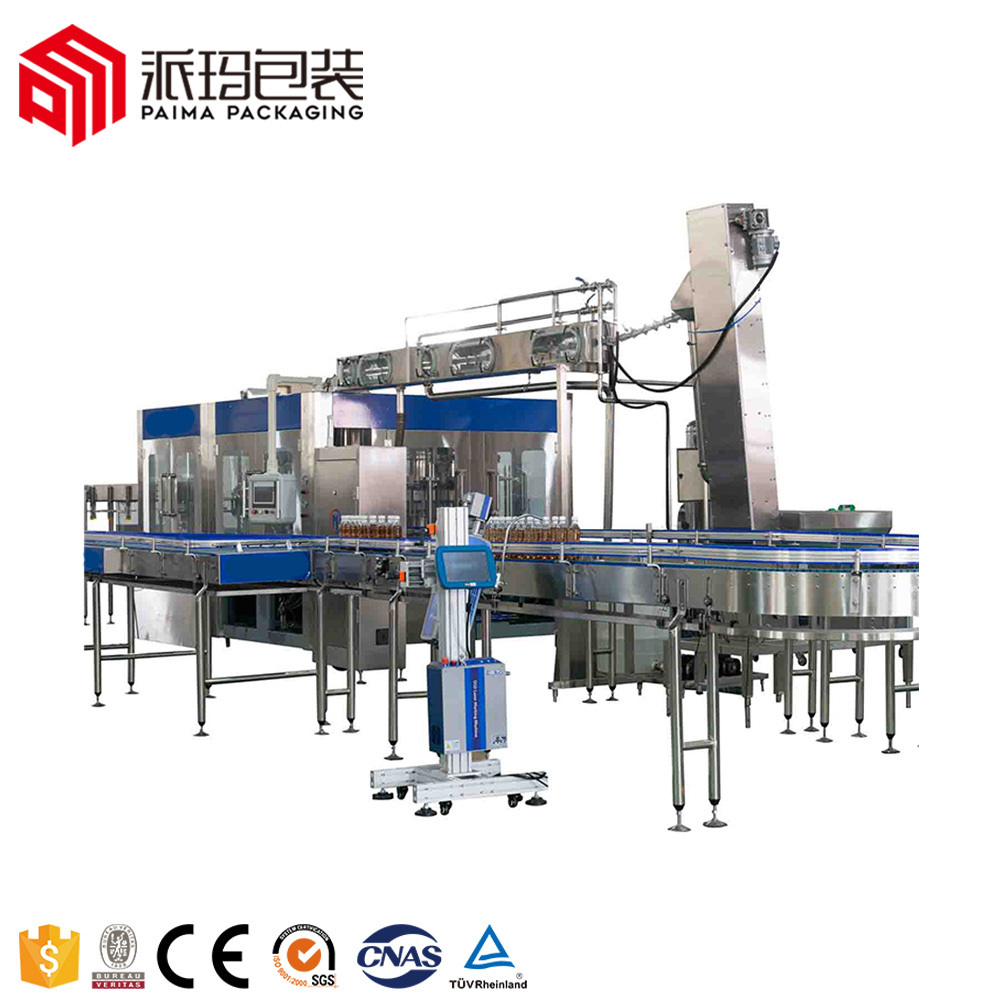

Soda drink / Sparkling beverage / Carbonated drink filling machines

Main Features of soft drink filling machine:

1. It is adopted that direct connection between air conveyor and inlet starwheel instead of screw and conveyor chains, which is easier for bottle changing.

2. There is no need to adjust the height of equipment through the neck holding tech for bottle transportation. And what is only to change some spare parts.

3. By 3-in-1 monoblock, the bottle goes through rinsing, filling, and capping with little abrasion, and the transferring is stable, bottle changing is easier.

4. High-speed filling line is clamp transferring technology. Bottle shapes are more varied, and the working table inside the machine is more laconic.

5. Especially designed stainless steel bottle clamp does not contact the thread parts of the bottleneck, avoiding the second contamination.

6. High speed and large flow filling valve assure the high filling speed and exact fluid level.

7. Parts in contact with the liquid are all of excellent stainless steel or food level plastic. The electric system is of international brand and achieves the national food sanitary standard.

8. The bottle-out starwheel is of screw down shape. When bottle size is changed, there is no need to adjust the transferring chain's height.

Working Principles of soft drink filling machines

The carbonated beverage filling machine is self-designed and manufactured according to the principle of equal pressure filling, which can fill liquid into the bottle washing machine sent by the bottle washing machine.

The filling valve adopts an equal pressure mechanical valve, the filling is fast and sensitive, and the filling level has high accuracy. The centering guide adopts guide rod centering and unique bottle mouth clamping technology, which can ensure the accurate sealing between the bottle mouth and the filling valve and reduce the leakage of materials from the bottle mouth. The main transmission adopts gear transmission, that is, open combined transmission, which has high efficiency, low noise, long service life, convenient maintenance and sufficient lubrication. The frequency converter is used to control the speed of the main motor of the machine, and the machine adopts stepless frequency conversion control. The bottle guide system has a simple structure and can be quickly and easily replaced according to the bottle type.

The whole machine adopts a bottleneck structure for transportation. The whole machine is automatically controlled by PLC, and online display of bottle jams, missing bottle caps and other faults. The material in the filling tank is automatically controlled, and the liquid level sensor detects the height of the liquid level to ensure a stable liquid level and reliable filling.

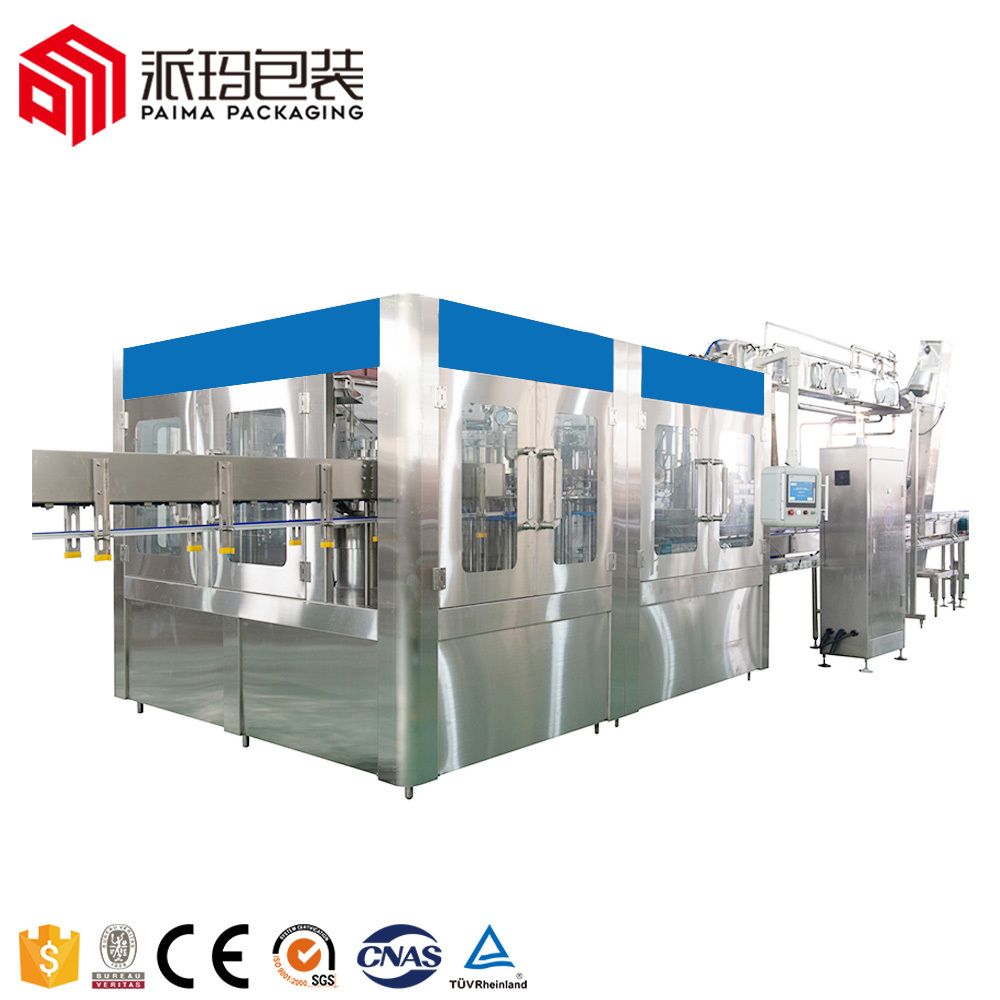

Specification

|

PROJECT

|

CARBONATED DRINK FILLING MACHINE

|

|

|

|

|

|

|||||

|

Model

|

12-12-5

|

18-18-6

|

24-24-8

|

32-32-10

|

40-40-12

|

50-50-15

|

|||||

|

Capacity (BPH)

|

2000-3000

|

3000-5000

|

5000-7000

|

7000-10000

|

10000-15000

|

16000-20000

|

|||||

|

Applicable bottle

|

φ=50-115 H=160-330 (200ML TO 2000ML) plastic screw cup or crown cap

|

|

|

|

|

|

|||||

|

Air press(Mpa)

|

≤0.4

|

|

|

|

|

|

|||||

|

Power supply

|

4.4 KW

|

5.2 KW

|

6.2 KW

|

6.2 KW

|

7.5 KW

|

11 KW

|

|||||

|

Overall dimension

|

2250×1650×2250

|

2600×1965×2250

|

2980×2200×2250

|

3880×2200×2250

|

4000×2250×2500

|

5500×3500×2500

|

|||||

|

Weight (KG)

|

2500

|

3500

|

4500

|

6000

|

7200

|

10000

|

|||||

|

ITEM

|

DEVICES

|

BRAND

|

|

1

|

PLC

|

SIEMENS

|

|

2

|

Inverter

|

SIEMENS

|

|

3

|

Touch Screen

|

SIEMENS

|

|

4

|

Switch

|

SIEMENS

|

|

5

|

Contactor

|

SIEMENS

|

|

6

|

Relayer

|

SIEMENS

|

|

7

|

Solenoid Valve

|

AIRTAC

|

|

8

|

Drive motor

|

FEITUO

|

|

9

|

Reducer

|

CNP

|

|

10

|

Water Pump

|

SKF

|

|

11

|

Main Bearing

|

AUTONICS

|

|

12

|

Sensor

|

AIRTAC

|

|

13

|

Air component

|

ABB

|

Details Images

Washing heads

1.Using unique design,avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the

pollution.

2.Washing pump is made of stainless steel.

3. By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

4. Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance.

Filling heads

1.Filling method for

equal pressure

filling.

2.Filling valve manufactured SUS 304/316L.

3.High precision, high speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance

.

Capping heads

1.Automatic check,no bottle no capping.

2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5.High efficiency centrifugal principle.

Related Products

Complete carbonated drinks production line

1. Water treatment system (quartz sand filter, active carbon filter, softner, RO system and so on)

2. Ozone generator sterilizer

3. Aseptic water storage tank

4. Sugar melting tank & syrup filter

5. Flavour blending tank & syrup cooler

6. Co2 drink mixer & Co2 filter

7. Water chiller

8. Auto bottle washing, filling and capping line

9. Labeling machine

10. Date of manufacture printer

11. Final products film packaging machine and so on.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches