Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Babies and kids

-

Design Style:

-

Chinese

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LIMIN, LIMIN

-

Model Number:

-

LM8886, PVC-lm8887

-

Type:

-

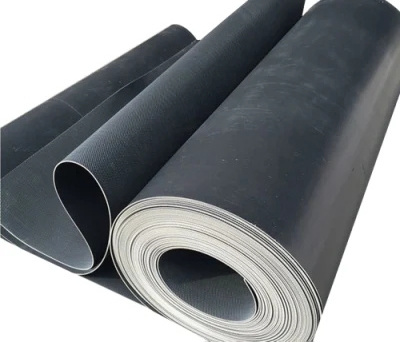

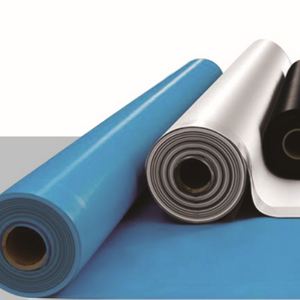

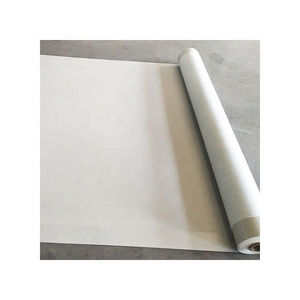

PVC, Plastic waterproof membrane

-

Color:

-

black/white/custom

-

MOQ:

-

25rolls

-

Surface:

-

Smooth Surface

-

Thickness:

-

1.0/1.5/2.0/custom

-

Weight:

-

70 - 120 kg

Quick Details

-

Warranty:

-

Lifetime

-

After-sale Service:

-

Free spare parts, Return and Replacement, Onsite Training, Onsite Inspection, Online technical support

-

Project Solution Capability:

-

Cross Categories Consolidation, 3D model design, total solution for projects, graphic design

-

Application:

-

Babies and kids

-

Design Style:

-

Chinese

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LIMIN, LIMIN

-

Model Number:

-

LM8886, PVC-lm8887

-

Type:

-

PVC, Plastic waterproof membrane

-

Color:

-

black/white/custom

-

MOQ:

-

25rolls

-

Surface:

-

Smooth Surface

-

Thickness:

-

1.0/1.5/2.0/custom

-

Weight:

-

70 - 120 kg

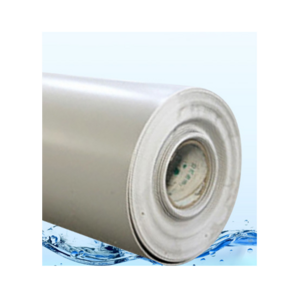

LIMIN(PVC) waterproofing membrane is a type of new high macro-molecular waterproofing membrane by adding plasticizer, filler, anti-oxidizer, ultraviolet light absorber and other auxiliaries with polyvinyl chloride resins as raw material.

Product features

1. High tensile strength , good elongation , strong applicability for base expansion or cracking deformation .

2. Large width ,high construction efficiency , small product consumption .

3.Good diffusion of water vapor , easy discharge of condensate , easy discharge of moisture left in the substrate

4. Root penetration resistance , chemical corrosion resistance and aging resistance ;

5. maintain good flexibility even at -25ºC

6.High Security without open flame installation

7. It used for exposed ,service life 10 years ; if unexposed used , the service life can be 50-100 years .

8. The artificial weathering time of Otai PVC is not less than 4100 hours.

9. Anti-Wind reach 135 PSF

Technical Data Sheet:

| Item | Desc. | National Standard | Our Product Property | ||

| 1 | Intermediate base the resin thickness /mm | ≥0.40 | 0.59 | ||

| 2 | Tensile Performance | Tension Strength /(N/cm) | Longitude | ≥250 | 317 |

| Latitude | ≥250 | 262 | |||

| Max tensile elongation /% | Longitude | ≥15 | 21 | ||

| Latitude | ≥15 | 23 | |||

| 3 | Heat-treatment dimensional stability /% | Longitude | ≤0.5 | 0.4 | |

| Latitude | ≤0.5 | 0.1 | |||

| 4 | Low-temperature Flexibility | -25ºCno crack | -25ºCno crack | ||

| 5 | Waterproofness | 0.3Mpa,2h waterproof | 0.3Mpa,2h waterproof | ||

| 6 | Shocking resistance | 0.5kg.m, watertight | 0.5kg.m, watertight | ||

| 7 | Anti Static Load | 20kg, watertight | 20kg, watertight | ||

| 8 | Joint peeling strength /(N/mm) | ≥3.0 | 3.2 | ||

| 9 | Trapezoid tear strength /(N/mm) | Longitude | ≥250 | 460 | |

| Latitude | ≥250 | 382 | |||

| 10 | Water adsorption(70ºC,168h) | After immersion | ≤4.0% | 3.9% | |

| After airing | ≥-0.40% | 0.82% | |||

| 11 | Heat-aging(80ºC, 672h) | Appearance | no bubbling, crack, layering, bond or hole | ||

| Retention of Max Tension /% | Longitude | ≥85 | 97 | ||

| Latitude | ≥85 | 105 | |||

| Max tensile elongation /% | Longitude | ≥80 | 89 | ||

| Latitude | ≥80 | 91 | |||

| Low-temperature Flexibility | -20ºC no crack | -20ºC no crack | |||

| 12 | Chemical Resistance | Appearance(5% H2SO4) | no bubbling, crack, layering, bond or hole | ||

| Retention of Max Tension /%(5% H2SO4) | Longitude | ≥85 | 101 | ||

| Latitude | ≥85 | 107 | |||

| Max tensile elongation /%(5% H2SO4) | Longitude | ≥80 | 88 | ||

| Latitude | ≥80 | 94 | |||

| Low-temperature Flexibility(5% H2SO4) | -20ºC no crack | -20ºC no crack | |||

| Appearance Ca(OH)2 | no bubbling, crack, layering, bond or hole | ||||

| Retention of Max Tension /% Ca(OH)2 | Longitude | ≥85 | 96 | ||

| Latitude | ≥85 | 102 | |||

| Max tensile elongation /% Ca(OH)2 | Longitude | ≥80 | 84 | ||

| Latitude | ≥80 | 83 | |||

| Low-temperature Flexibility Ca(OH)2 | -20ºC no crack | -20ºC no crack | |||

| Appearance(10% NaCl) | no bubbling, crack, layering, bond or hole | ||||

| Retention of Max Tension /%(10% NaCl) | Longitude | ≥85 | 101 | ||

| Latitude | ≥85 | 105 | |||

| Max tensile elongation /%(10% NaCl) | Longitude | ≥80 | 92 | ||

| Latitude | ≥80 | 92 | |||

| Low-temperature Flexibility(10% NaCl)) | -20ºC no crack | -20ºC no crack | |||

| 13 | Artificial Weather Accelerated Aging | Test Period /h | 1500 | 5000 | |

| Appearance | no bubbling, crack, layering, bond or hole | ||||

| Retention of Max Tension /% | Longitude | ≥85 | 97 | ||

| Latitude | ≥85 | 106 | |||

| Max tensile elongation /% | Longitude | ≥80 | 83 | ||

| Latitude | ≥80 | 90 | |||

| Low-temperature Flexibility | -20ºC no crack | -20ºC no crack | |||

Package, transportation and storage:

1. Packed by plastic bag or adhesive tape.

2. During transportation and storage, keep the package well , put them in a dry airy place, keep away from direct sunlight, acids, alkalis, oil and organic solvents.

3. The shelf life is 12 months under normal storage and transportation conditions. After that period, the product can still be used if it complies with all the items in the specification.