- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

1000L

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

FARFLY

-

Voltage:

-

110V/220V/380V/440V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

22 kW

-

Product Name:

-

Rubber or Plastic Mixer

-

Machine Type:

-

Disperser

-

Contact Material:

-

SUS304

-

Function:

-

Paint disperser and mixing

-

Motor:

-

Normal / Explosion-proof

-

Speed Control:

-

Inverter frequency control

-

Usage:

-

Paint mixing machine

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

Quick Details

-

Barrel Volume (L):

-

1000 L

-

Max. Loading Volume (L):

-

1000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 1450 r.p.m

-

Max. Loading Capacity:

-

1000L

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

FARFLY

-

Voltage:

-

110V/220V/380V/440V

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

22 kW

-

Product Name:

-

Rubber or Plastic Mixer

-

Machine Type:

-

Disperser

-

Contact Material:

-

SUS304

-

Function:

-

Paint disperser and mixing

-

Motor:

-

Normal / Explosion-proof

-

Speed Control:

-

Inverter frequency control

-

Usage:

-

Paint mixing machine

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

Working Principle

FDG CE Certified Superfine Polyurethane Dispersing Machine

FDG CE Certified Superfine Paint Dispersing Machine is one kind high speed disperser, which can be mounted on the floor or on suitable platform. During operation, the dispersing head is raised to a suitable height by hydraulic pumping system, and corresponding vessel is located under the stirring disc. After charging the vessel with raw materials, lowering the stirring disc into the vessel, then start rotating the stirring disc from low to high speed. While dispersed the raw materials to fine compound, raising the disc out of the vessel and removing the vessel with another batch.

Technical Date

|

Type/

Parameter |

Power

(kw) |

Speed

(rpm) |

Disc diameter

(mm) |

Lifting height

(mm) |

Pump power

(Kw) |

Handling capacity

(L) |

Weight

(Kg) |

|

FDG1.5/2.2

|

1.5/2.2

|

0-1450

|

150

|

600

|

0.55

|

50-100

|

120

|

|

FDG4/5.5

|

4/5.5

|

0-1450

|

200

|

800

|

0.55

|

100-200

|

400

|

|

FDG7.5/11

|

7.5/11

|

0-1450

|

250

|

900

|

0.55

|

400-600

|

800

|

|

FDG22/30

|

22/30

|

0-1450

|

350

|

1200

|

0.75

|

600-1200

|

1500

|

|

FDG37/45

|

37/45

|

0-1450

|

400/500

|

1300

|

1.1

|

1200-2000

|

2000

|

|

FDG55/75

|

55/75

|

0-1450

|

500/550

|

1600

|

1.5

|

2000-3000

|

2500

|

Specific characteristics

FDG CE Certified Superfine Paint Dispersing Machine

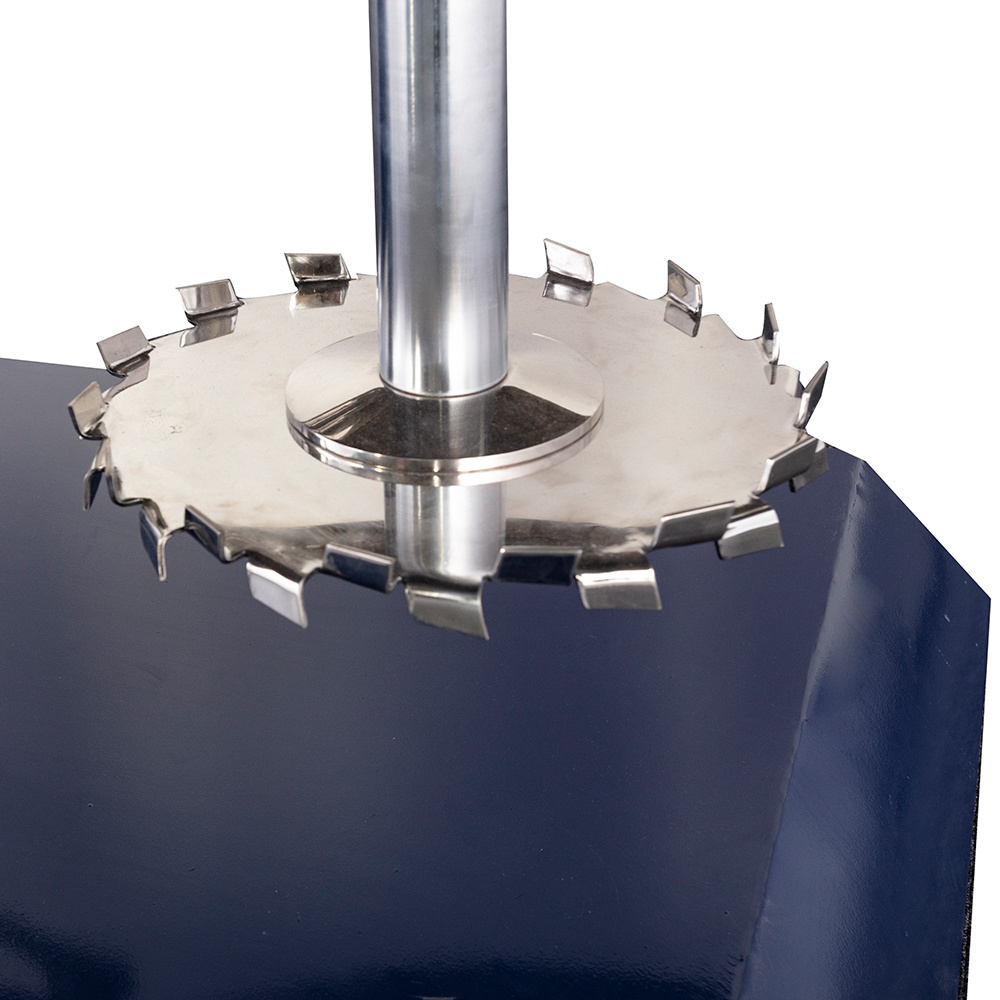

Motor sizes range from 1 Hp up to 300 Hp. Normal type or explosion proof with high efficiency motors are optional for selection. Contact parts (MOC) can be chosen by customers from AISI 304 L, AISI 316 L, Mild Steel, MSRC and other materials. V-Belt driven sheaves are the power transmitting component in this machine.

Variable frequency drives are provided for speed control. The drive comes with a fully automatic control panel with state of the art electronics. Speeds can be adjusted by inverter controlled motor in infinitesimal increments. Tip speeds of the saw tooth impellers is optimized designed to meet different materials with various solid content to reach the best compound requirements.

Vacuum functions can be provided in certain models according to diverse customer requirements.

These stirring devices form very good vortexes in the mixture. They can be used for high shear blending, mild blending or

other operations such as tinting, dissolving, sparing, particle size reduction, let down, dispersing of inks and paints, coatings, pharmaceuticals, allied chemicals, etc.

We provide a wide range of mixing and cutting impellers, based on the type of operation. These impellers are detachable

from the drive shaft and can be easily interchanged. All dynamic parts are balanced in stationary and in rotating stages.

Every aspect of this machine is created with advanced engineering technology.

Variable frequency drives are provided for speed control. The drive comes with a fully automatic control panel with state of the art electronics. Speeds can be adjusted by inverter controlled motor in infinitesimal increments. Tip speeds of the saw tooth impellers is optimized designed to meet different materials with various solid content to reach the best compound requirements.

Vacuum functions can be provided in certain models according to diverse customer requirements.

These stirring devices form very good vortexes in the mixture. They can be used for high shear blending, mild blending or

other operations such as tinting, dissolving, sparing, particle size reduction, let down, dispersing of inks and paints, coatings, pharmaceuticals, allied chemicals, etc.

We provide a wide range of mixing and cutting impellers, based on the type of operation. These impellers are detachable

from the drive shaft and can be easily interchanged. All dynamic parts are balanced in stationary and in rotating stages.

Every aspect of this machine is created with advanced engineering technology.

Hot Searches