- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1.2*1.1*1.3M

-

Year:

-

2021

-

Weight (KG):

-

160 kg

-

Power (kW):

-

3kw

-

Name:

-

Truck Tire Sidewall Cutter Car Tire Sidewall Cutting Recycling Machine

-

Usage:

-

tire cutting,making tire strips

-

Raw product:

-

waste tires

-

Suitable for waste tires:

-

400-1000mm

-

Other names:

-

Waste Tire Recycling Machine

-

Related Products:

-

Tire shredder,Tire raking machine,etc

-

Capapcity:

-

1000pcs/day

-

Processing:

-

Tire Cutting Recycling Work

-

Note:

-

Tire Recycling Machine

-

Work Pressure:

-

90Mpa

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MG

-

Model Number:

-

MG-T750

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1.2*1.1*1.3M

-

Year:

-

2021

-

Weight (KG):

-

160 kg

-

Power (kW):

-

3kw

-

Name:

-

Truck Tire Sidewall Cutter Car Tire Sidewall Cutting Recycling Machine

-

Usage:

-

tire cutting,making tire strips

-

Raw product:

-

waste tires

-

Suitable for waste tires:

-

400-1000mm

-

Other names:

-

Waste Tire Recycling Machine

-

Related Products:

-

Tire shredder,Tire raking machine,etc

-

Capapcity:

-

1000pcs/day

-

Processing:

-

Tire Cutting Recycling Work

-

Note:

-

Tire Recycling Machine

-

Work Pressure:

-

90Mpa

Product Description

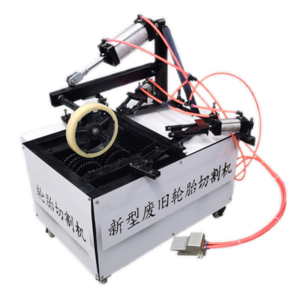

Truck Tire Sidewall Cutter Car Tire Sidewall Cutting Recycling Machine

Introduction

It's mainly used for recycling waste tires,cutting waste tires into tire side and crown, and then building strips and

plastic blocks,Put the old tire on the disc platform, rotate the middle handwheel, the four-jaw clamp will firmly jam the inner ring of the tire,start the power supply, the working platform rotates, cut the cutter according to the need, slowly cut into the tire, step by step, until the tire side is cut off.The cutter is made of hard alloy, which is hard and durable and can be used repeatedly.The final product is waste tire strips.

plastic blocks,Put the old tire on the disc platform, rotate the middle handwheel, the four-jaw clamp will firmly jam the inner ring of the tire,start the power supply, the working platform rotates, cut the cutter according to the need, slowly cut into the tire, step by step, until the tire side is cut off.The cutter is made of hard alloy, which is hard and durable and can be used repeatedly.The final product is waste tire strips.

Specification

|

Product Name

|

Tire Cutting Machine Waste Tire Recycling Machine

|

|

Capacity

|

200-300pcs/hour;1000pcs/day

|

|

Raw diameter of waste tires

|

400-1000mm Mainly below 750mm

|

|

Working compressure

|

90Mpa

|

|

Power

|

3kw

|

|

Voltage

|

380V/220V

|

|

Dimension

|

1.2*.1*1.3M

|

|

Weight

|

160kgs

|

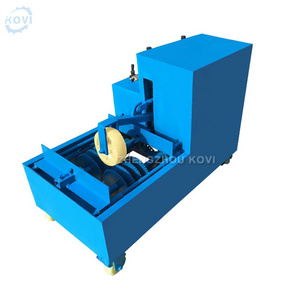

Features

1.This is a double-sided cutting machine for tires.

2. The characterized is bead on both sides of the tire.And can be cut off at one time. It is mainly used for the processing of

used tires, especially for the bead cutting of trolley tires (600-800mm), which greatly improves the efficiency of tire ring

cutting.

3. Remove the bead on both sides of the tire at the same time,no need manual flipping

4. Fast cutting, complete bead cutting in 5 seconds

5. Distribution box control, simple and safe operation

6. Large output, can process200-400 tires per hour

2. The characterized is bead on both sides of the tire.And can be cut off at one time. It is mainly used for the processing of

used tires, especially for the bead cutting of trolley tires (600-800mm), which greatly improves the efficiency of tire ring

cutting.

3. Remove the bead on both sides of the tire at the same time,no need manual flipping

4. Fast cutting, complete bead cutting in 5 seconds

5. Distribution box control, simple and safe operation

6. Large output, can process200-400 tires per hour

Product Details

Packing & Delivery

Package:Wooden Crate or Pallet or bare package in standard containers for export;

Shipment:

All machines will be sent by sea, if you need other kind of transportation, please inform us in advance.

And all machines would be shipped in 7 days after the receipt of payment. Before and after shipping, we will take photos

ofmachines and send photos to client.

And all machines would be shipped in 7 days after the receipt of payment. Before and after shipping, we will take photos

ofmachines and send photos to client.

Hot Searches