Specifications

• Polished high carbon steel

• Hardened, ground teeth

• Hardened back

Features

• Clean and sanitary operation

• Fast, smooth and clean cuts, with less waste

• Accurate cuts with less effort

Meat Types

• Fresh Frozen meat

• Poultry

• Fish

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1year

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hongsheng

-

Model Number:

-

HS459611

-

Product Name:

-

Meat Bone Saw African market hot selling meat blades

-

Blade Material:

-

SK75 SK5

-

band saw blade:

-

narrow.wide.customized

-

MOQ:

-

10pcs

-

Application:

-

meat icy bonecutting

-

Color:

-

Bright,white

-

Teeth type:

-

customized, harden,non-harden

-

Technology:

-

teeth punching, teeth shape

-

Usage:

-

Cutting Meat and bone

-

factory:

-

yes

Quick Details

-

Blade Length:

-

6in, 6 1/2in, 10in

-

Finishing:

-

White

-

Size:

-

(0.15MM-4MM)*(0.5MM-400MM)

-

Warranty:

-

1year

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hongsheng

-

Model Number:

-

HS459611

-

Product Name:

-

Meat Bone Saw African market hot selling meat blades

-

Blade Material:

-

SK75 SK5

-

band saw blade:

-

narrow.wide.customized

-

MOQ:

-

10pcs

-

Application:

-

meat icy bonecutting

-

Color:

-

Bright,white

-

Teeth type:

-

customized, harden,non-harden

-

Technology:

-

teeth punching, teeth shape

-

Usage:

-

Cutting Meat and bone

-

factory:

-

yes

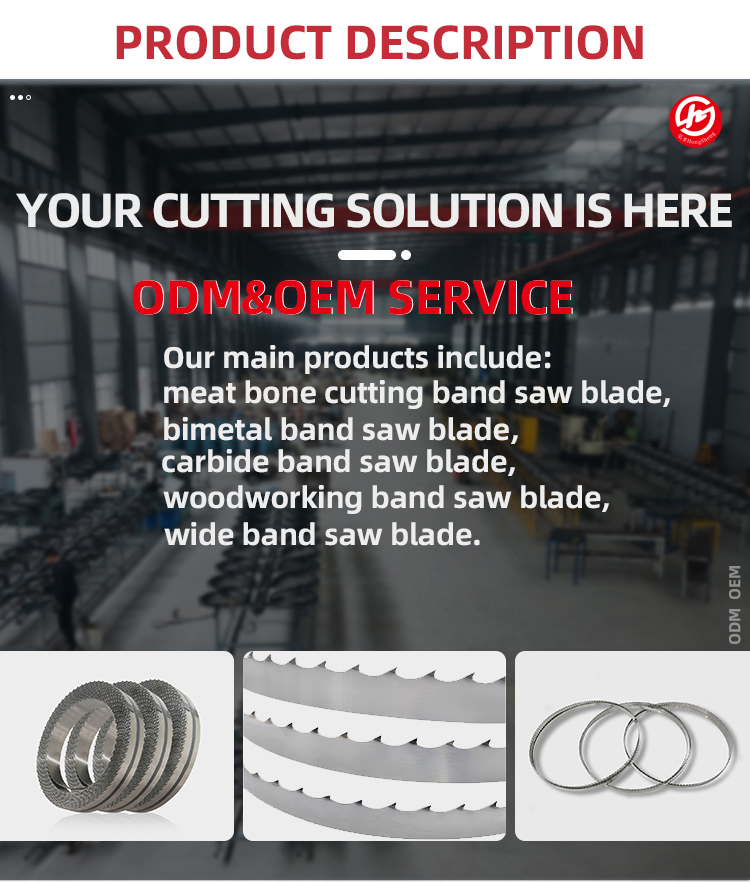

Product Description

Meat Band Saw Blades

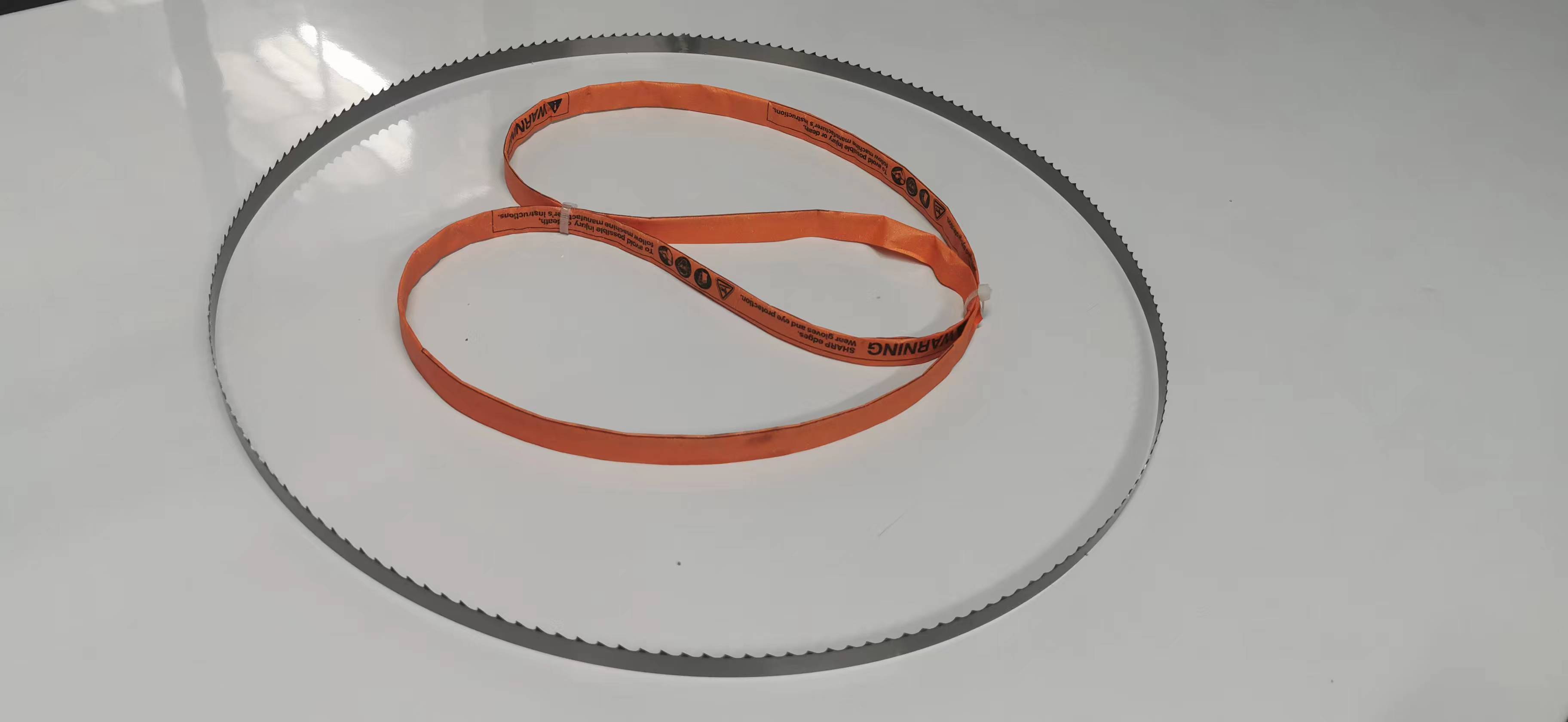

3TIP / 4TIP 16/19mm * 0.56mm Hojas de sierra de cinta estrecha para corte de carne / hueso

3TIP / 4TIP 19 mm * 0,56 mm estrecho Hojas de sierra de cinta para corte de carne / huesos

Hojas de sierra de cinta estrechas para corte de carne y huesos, completas con puntas dentadas HF que se endurecen y no endurecen, todos los tamaños pueden estar disponibles. Espesor: 0,50 / 0,55 mm / 0,56 mm / 0,6 mm Ancho: 12,7 / 13/16/19 / 21mm TPI: 3/4 Longitud: soldada según necesidad del cliente o 100 metros por bobina. Materias primas: CK75, SK5,51CRV4 M42 etc.

Specification

|

Blade Width * Thickness

|

|

Tooth Pitch

|

|

||

|

13*0.56

|

1/2*0.022

|

3TPI

|

4TPI

|

||

|

16*0.5

|

5/8*0.020

|

3TPI

|

4TPI

|

||

|

16*0.56

|

5/8*0.022

|

3TPI

|

4TPI

|

||

|

19*0.5

|

3/4*0.020

|

3TPI

|

4TPI

|

||

|

19*0.56

|

3/4*0.022

|

3TPI

|

4TPI

|

||

Application

Por lo general, detalles de tamaño:

Por lo general, detalles de tamaño:

Espesor: 0,50 / 0,55 mm Ancho: 12,7 / 16/19 mm TPI: 3/4 Longitud: soldada según necesidad del cliente o 100 metros por bobina. Materias primas: CK75, SK5,51CRV4

Espesor: 0,50 / 0,55 mm Ancho: 12,7 / 16/19 mm TPI: 3/4 Longitud: soldada según necesidad del cliente o 100 metros por bobina. Materias primas: CK75, SK5,51CRV4

Por lo general, detalles de tamaño:

Packing & Delivery

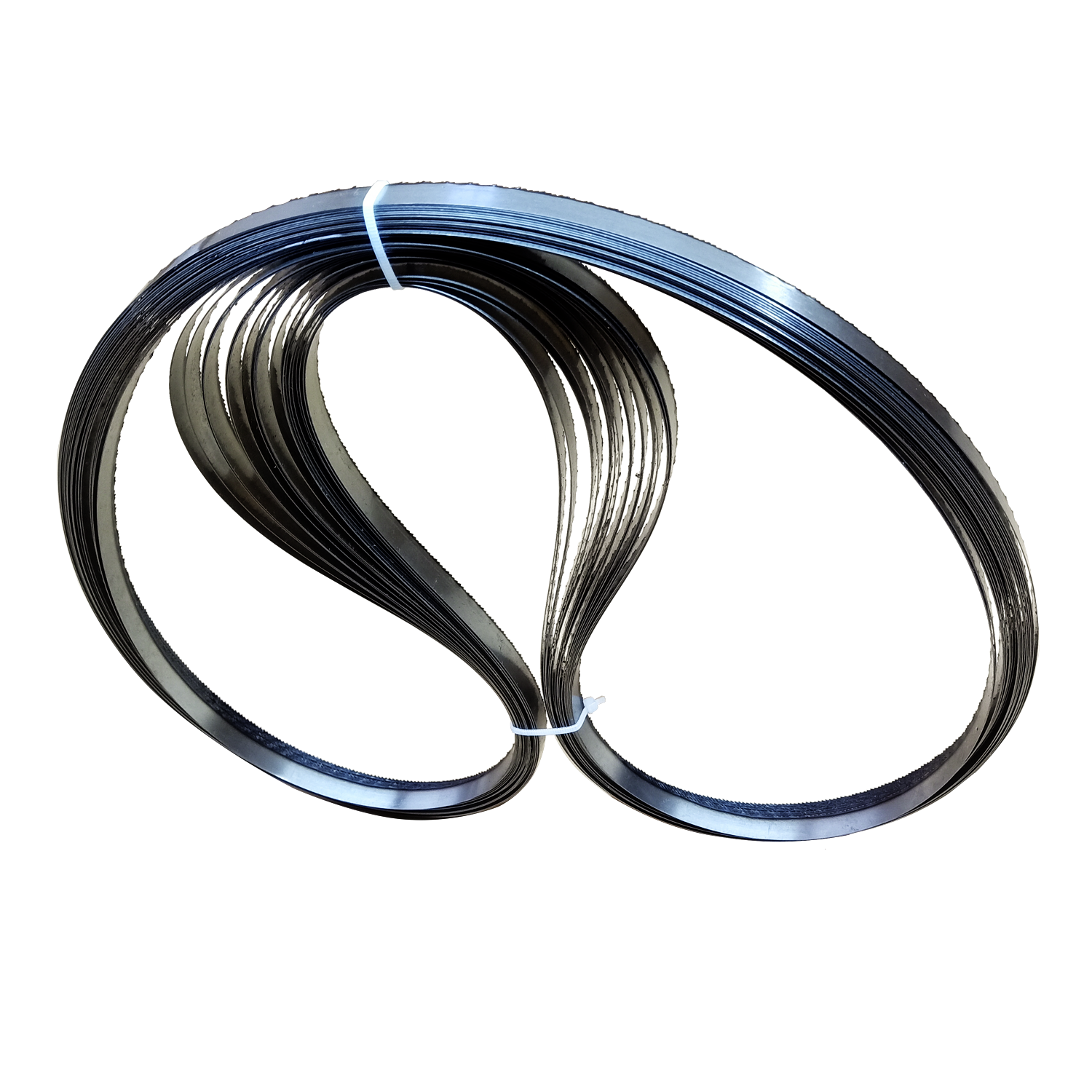

Paso uno:

Cada hoja de sierra está cubierta con una funda protectora de goma, que es conveniente para la conservación y ahorro de espacio durante el envío

Segundo paso:

El método de embalaje en forma de 8 es el método de embalaje que ahorra más espacio, lo que puede reducir el espacio ocupado por

los productos y ahorrar el costo de la logística y el transporte internacionales.

los productos y ahorrar el costo de la logística y el transporte internacionales.

Paso tres:

El tercer embalaje se empaqueta en cualquier caja de cartón, y el exterior se fija en forma de pozo con una cinta de refuerzo de

plástico, lo cual es muy conveniente para la carga y descarga manual o con montacargas.

plástico, lo cual es muy conveniente para la carga y descarga manual o con montacargas.

Band Saw Blade TIPS

What should be paid attention to when using a band saw blade?

2.

When feeding, be sure to keep the material straight, and do not apply force when the feeding is not smooth, which will cause the material to rebound and the band saw blade to collapse, resulting in personal injury.

3

.If there are abnormal noises, abnormal vibrations, unsmooth cut surfaces, or distortion of the band saw blade body during the operation, stop the operation immediately. Continuing the operation will cause the teeth to collapse, pull the teeth, and severely wear the saw teeth of the band saw blade, etc., resulting in property loss.

4

.Before operation, please check whether the material to be cut is abnormal or not suitable for band saw cutting.

5

.If the sawing effect is unsatisfactory, please adjust the sawing parameters in time or replace the band saw blade.

6

.

Keep your machine properly aligned by making sure the guides are correctly positioned so the blade always tracks in the center of the guides. Look at the blade scrapers to make sure they are not hitting the blade teeth and dulling them.

7

.Be sure the saw blade tracks straight. Adjust the blade tension so it will not waver – too much tension and it will break. Adjust the blade back-up bearings so they only touch and support the back of the blade when the machine is running.

8

.Let the blade do the work so it will cut straight. If the blade is not worn out, it should cut the meat easily.

9

.Keep your saw guides, blade cleaners, fiber support blacks and back-up bearings in good condition. These are not expensive parts, but they affect the performance of the blade and keep it working longer.

10.

Keep the wheels clean and wheel scrapers in good condition. Make sure that the blade is aligned properly so it doesn’t ride on the wheel flanges.

The above are the matters needing attention in the use of the band saw blade. Only the correct use of our band saw blade can better prolong the life of the band saw blade.

Production Procedure

1. Convey Materials

All steel coils should be naturally flat, smooth surface,no pits, no break,no distortion phenomenon,scraping sides to burr and along within the bending parameter list or straightness deviation <3mm/5m.

Hongsheng Steel strip for the manufacture of wood band saws is characterized by higher quality products and with more efficiency production to solve the focus on sickle-bending,twist degree, transverse straightness,flatness,high tensile strength,especial applications in saws blade.

2. Tooth Punching

Teeth Punching based on customerised width, TPI, Teeth Form, setting teeth ect to be 100% customerization products.

3. Hardening Teeth

To allow a high carbon content that allows the teeth to be hardened after teeth punched and set. This make for a durable blade that can withstand the heat and abrasion from re-sawing. Tooth point hardness HRC58-62.

4.Welding

Automatic welding machines,which allow welding bandsaw blades from 10mm to 250mm for all types of carbon steel band saw blade.We have professional technology provides the highest quality in all types of welding with strict heat control for all the welds.

5.Sharpening

To make the teeth sharp for best cutting performance

6.Grinding Teeth

To grinding the tooth so can be repeatly used.

7.Quality Inspection

8.Packing

Each welded blade or 2-5pcs are packed with plastic film, and anti-rust paper or rubber in carton boxes.

All coiled band saw blade are oiled packed with plastics and str

ong

metal pallet.

9.Shipments

Standard package for export shipment via parcel, express, LCL, sea, truck, train.

Factory

Hongsheng Saws manufacturing Co.,LTD

Hongsheng Saws Manufacturing has advance facilities for making different sizes of band saw blades for meat, food, wood, stone ,metal cutting. Our factory is located in high-tech industry zone, Xinyu City,JiangXi province, China. Occupying 6000 square meters manufacturing area, we own more than 100 staff, including senior technical staff, 30 mild-level technical staff as well as series of facilities for production of various type of band saw blades, we have equipment for teeth punching, teeth setting, welding machine, and the teeth point hardening etc.Over 15 years experience in this industry, hongsheng has been dedicating self to expending target markets and updating sophisticated advanced equipment to improve our products to higher level. We strictly make production according to China standard like YB/T5062-2007, JB/T8087-1999 and relevant national standards in cold rolled steel strips for saw blade,supplying excellent quality to clients.

Hongsheng Saws Manufacturing has advance facilities for making different sizes of band saw blades for meat, food, wood, stone ,metal cutting. Our factory is located in high-tech industry zone, Xinyu City,JiangXi province, China. Occupying 6000 square meters manufacturing area, we own more than 100 staff, including senior technical staff, 30 mild-level technical staff as well as series of facilities for production of various type of band saw blades, we have equipment for teeth punching, teeth setting, welding machine, and the teeth point hardening etc.Over 15 years experience in this industry, hongsheng has been dedicating self to expending target markets and updating sophisticated advanced equipment to improve our products to higher level. We strictly make production according to China standard like YB/T5062-2007, JB/T8087-1999 and relevant national standards in cold rolled steel strips for saw blade,supplying excellent quality to clients.

Hot Searches