- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

500 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinobender

-

Year:

-

2023

-

Voltage:

-

220V/380V/440V

-

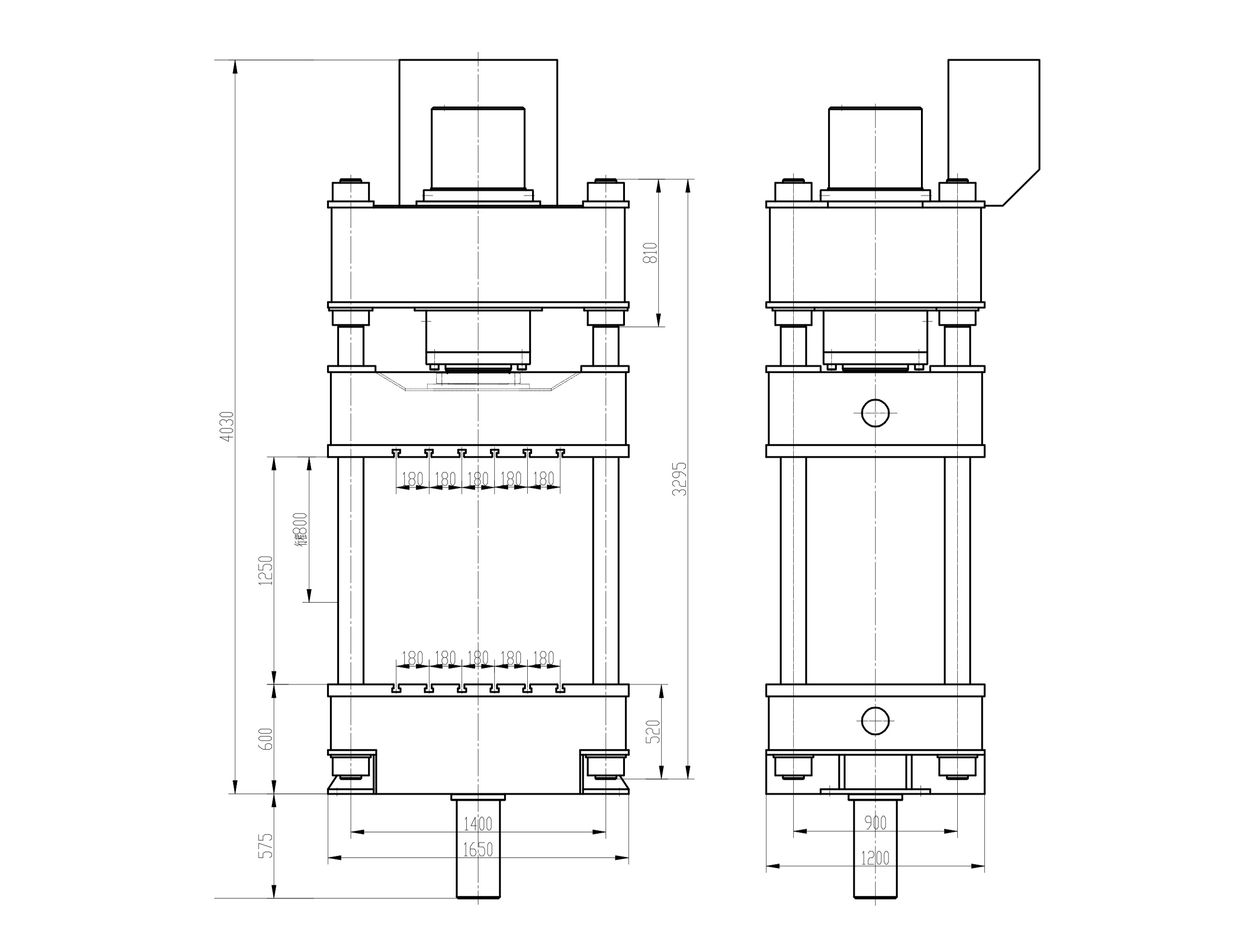

Dimension(L*W*H):

-

1650x1200x4030

-

Weight (T):

-

12.5 T

-

Model Number:

-

YHD32-315

-

Motor Power (kw):

-

18.5 kw

-

rated force:

-

3150KN

-

Keyword:

-

hydraulic press

-

Usage:

-

Metal Forming Machine

-

Function:

-

straightening

-

Product name:

-

four columns hydraulic press

-

Power Source:

-

hydraulic

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

800

-

Ejector Force (kN):

-

630

-

Return Force (kN):

-

500 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinobender

-

Year:

-

2023

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1650x1200x4030

-

Weight (T):

-

12.5 T

-

Model Number:

-

YHD32-315

-

Motor Power (kw):

-

18.5 kw

-

rated force:

-

3150KN

-

Keyword:

-

hydraulic press

-

Usage:

-

Metal Forming Machine

-

Function:

-

straightening

-

Product name:

-

four columns hydraulic press

-

Power Source:

-

hydraulic

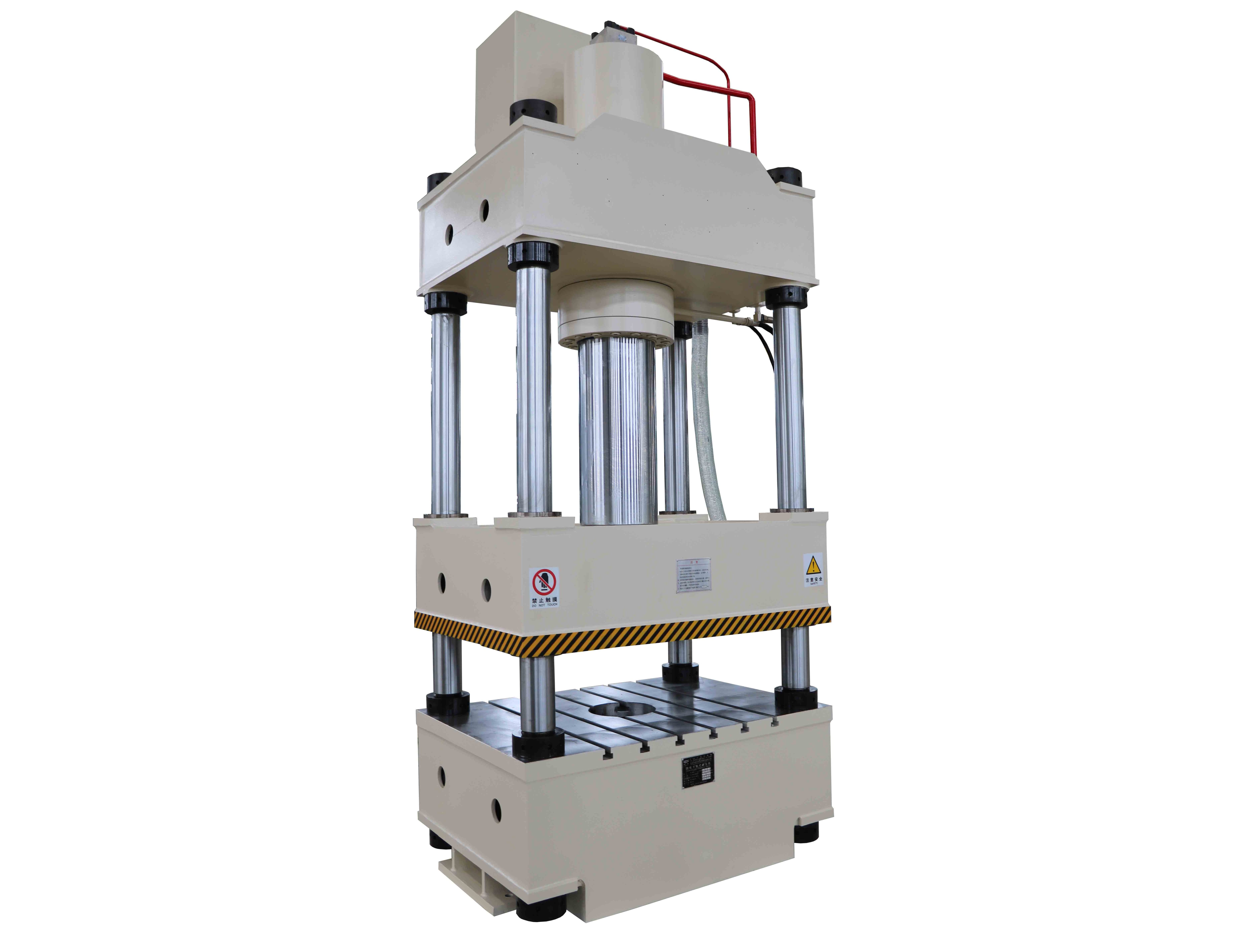

Four Columns Hydraulic Press Machine

1. Model: YHD32-315

2. Features

--Hydraulic driving

--Four columns, three beams

--Inserted integrated hydraulic block, large flow, small interior leakage, small impact

--Independent electrical control system, convenient to be operated and easy to be maintained

--Centralized control panel

--Three operating choice: adjustment, manual, semi-auto

--Two processing technique: fixed stroke forming process, fixed pressure forming process

--With pressure endure and time relay functions

3. Parameters

|

|

|

YHD32-315 |

|

|

Rated force |

KN |

3150 |

|

|

Knock out force |

KN |

630 |

|

|

Return force |

KN |

500 |

|

|

Ram stroke |

mm |

800 |

|

|

Knock out stroke |

mm |

300 |

|

|

Max. daylight |

mm |

1250 |

|

|

Ram speed |

stroke |

mm/s |

100 |

|

Pressing |

mm/s |

4-10 |

|

|

Return |

mm/s |

70 |

|

|

Knock out speed |

Knock out |

mm/s |

55 |

|

Return |

mm/s |

145 |

|

|

Table size |

L-R |

mm |

1250 |

|

F-B |

mm |

1200 |

|

|

Outline dimension |

L-R |

mm |

1650 |

|

F-B |

mm |

1200 |

|

|

Height |

mm |

4030 |

|

|

Motor capacity |

KW |

18.5 |

|

|

Weight |

kg |

12500 |

|

4. Structure

-- control buttons

The control panel is separated from the main structure for convenience of operation. The panel consists of a number of push buttons and emergency stop.

The main operation pressing is controlled by two press buttons, providing a bi-manual operation to safeguard the operator from potential harm.

Two types of operation way,

a) inch operation: press one button to get one action, mainly used to adjust the machine.

b) semi-automatic: press bi-manual button to finish one single complete working cycle.

--main frame

The main structure of the press consists of three horizontal steel structures and four columns, with high rigidity. The four columns connect two stationary plates (the crown and the work table). There is a (up/down) sliding plate (beam) between the stationary plates. The hydraulic cylinder mounted between the crown and the beam are driving the beam and delivering the 4 00 ton press power.

The complete construction is created from high quality steel (Q235) with exception of columns, pistons and other machined parts; these are constructed from C45 or equivalent materials. After completion the structure is sandblasted and conserved with an multi-layer industrial coating.

--cylinder

--hydraulic station

The hydraulic unit is placed on the side of the press and connected to it by flexible high pressure hoses and a multi-signal electrical connection. The unit consists of one main pump for pressing action , combined with an oil tank and filter unit.

--Column

Columns are constructed from C45 forging steel, heat treatment.HRC42-50

--beam & worktable

Crown/beam/table, steel welded, heat treatment to remove the inner strength, T-slot to be processed on the surface of the beam/table.

--Bi-manual button operation

--limit switch

The beam strokes were controlled by the limit switches, which can be adjusted according the practical use.

--application

Drawing ,bending ,flanging, cold extruding, blanking processes for metal materials; straightening, press-in and forming processes for powder and abrasive products, plastic and insulation materials.