- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

250

-

Product name:

-

candle pouring machine

-

Gross Weight:

-

250KG

-

Payment:

-

T/T

-

Capacity:

-

200pcs/batch

-

Keywords:

-

Semi Automatic Small Candle Making Machine

-

Usage:

-

Making Candles

-

Function:

-

Normal Candle

-

Candle Size:

-

Diameter Customized . Length

-

Candle shape:

-

Custom-made

-

Port:

-

Dalian Port

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

HD

-

Production Capacity:

-

100%

-

Weight:

-

250

-

Product name:

-

candle pouring machine

-

Gross Weight:

-

250KG

-

Payment:

-

T/T

-

Capacity:

-

200pcs/batch

-

Keywords:

-

Semi Automatic Small Candle Making Machine

-

Usage:

-

Making Candles

-

Function:

-

Normal Candle

-

Candle Size:

-

Diameter Customized . Length

-

Candle shape:

-

Custom-made

-

Port:

-

Dalian Port

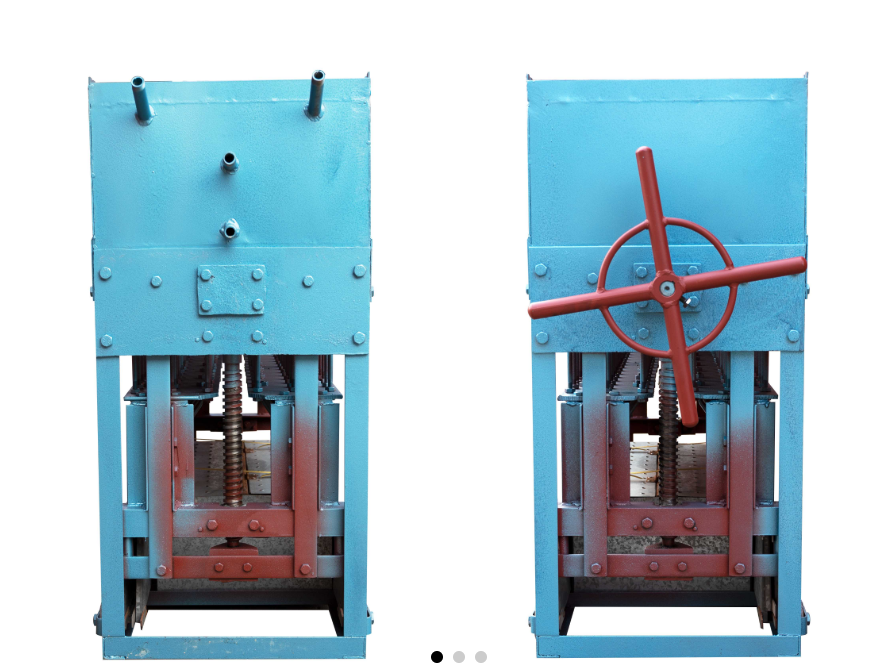

This machine can be made by customers require on the size of candle.

The taper machine operation steps information as follows:

First, Thread the wick through the hole of each mould.

Pour the liquid wax into the mould of the machine until the liquid wax full of mould trough.

Second, some minutes later, The cold water(This is cycle---enter into one pipeline and out of another pipe line. )

Finally, the worker should turn the handle which is beside of the machine.

The taper candle will be pushed out of the mould.

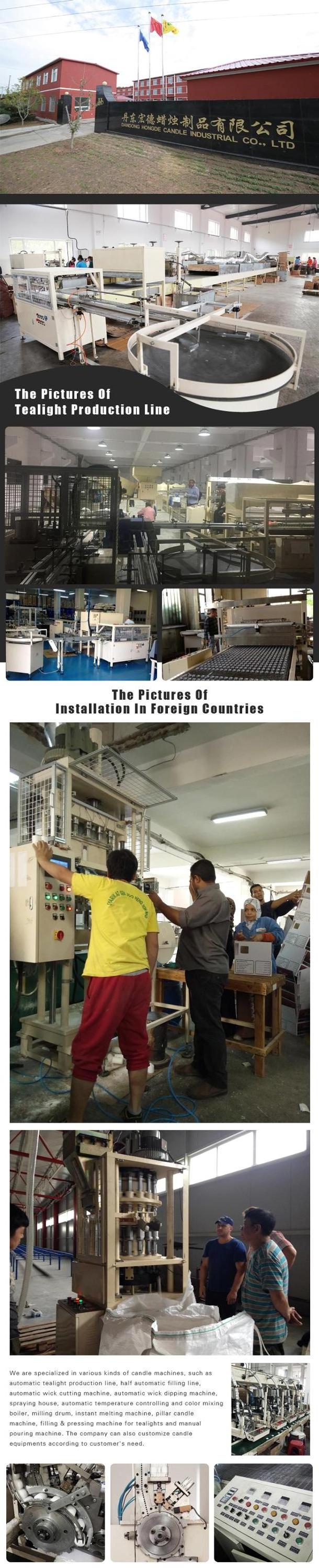

Machine installed in candle factory in India

We are also the exhibitor of Canton Fair

Other candle accessories