Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

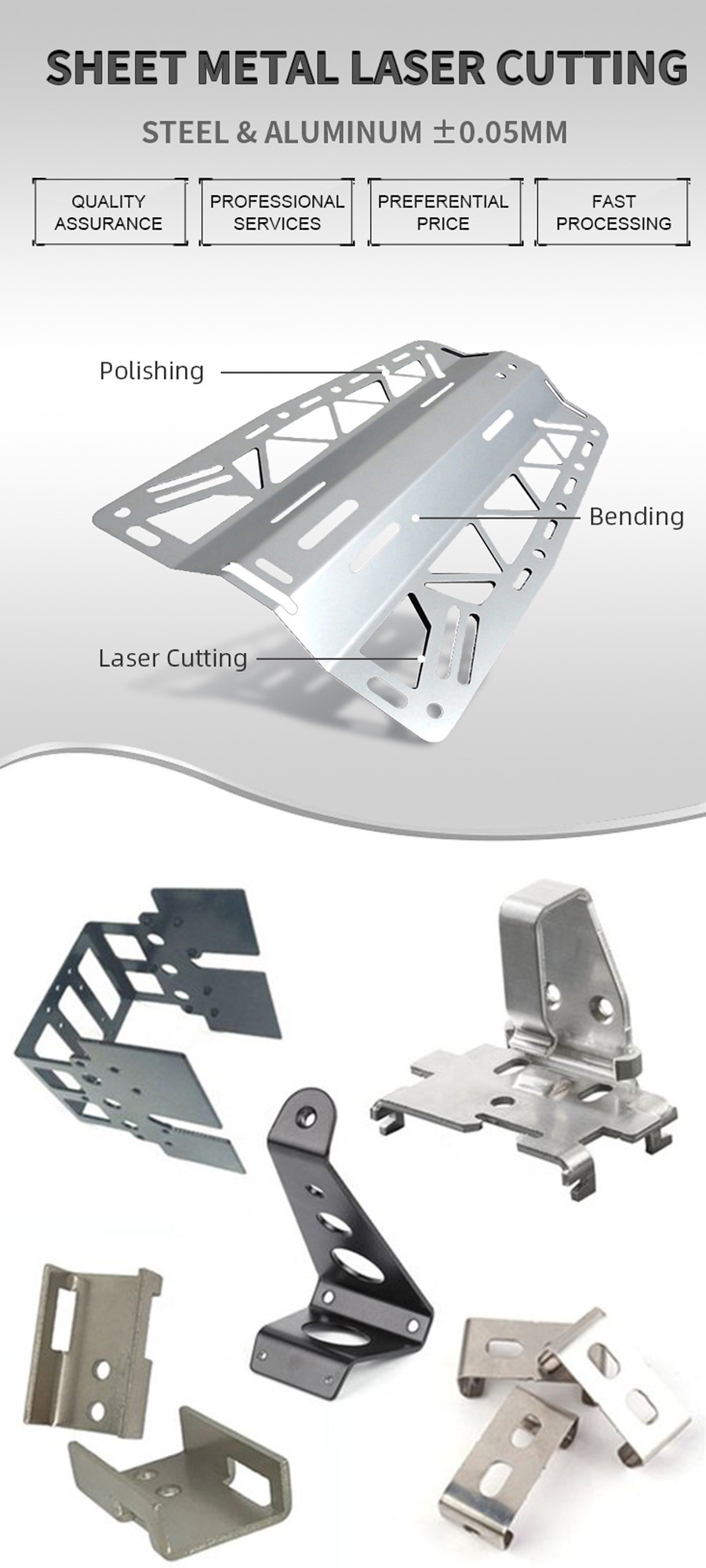

Laser Cutting Bending Stainless Steel Sheet Metal Fabrication

-

Keyword:

-

sheet metal fabrication

-

Tolerance:

-

Min +/-0.01mm

-

Surface Roughness:

-

Min Ra0.1~3.2

-

Surface Treatment:

-

Anodizing/electroplating/PVD/Nickel/Chrome Plating

-

Type available:

-

LASER CUTTING

-

QC Control:

-

100% QC

-

OEM/ODM:

-

OEM ODM CNC Drilling Milling Machining Service

-

Application:

-

Medical, Electronic, Architecture, Lighting, Textile machinery etc

-

Production time:

-

10--25 Work Days

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

003

-

Product name:

-

Laser Cutting Bending Stainless Steel Sheet Metal Fabrication

-

Keyword:

-

sheet metal fabrication

-

Tolerance:

-

Min +/-0.01mm

-

Surface Roughness:

-

Min Ra0.1~3.2

-

Surface Treatment:

-

Anodizing/electroplating/PVD/Nickel/Chrome Plating

-

Type available:

-

LASER CUTTING

-

QC Control:

-

100% QC

-

OEM/ODM:

-

OEM ODM CNC Drilling Milling Machining Service

-

Application:

-

Medical, Electronic, Architecture, Lighting, Textile machinery etc

-

Production time:

-

10--25 Work Days

Product Paramenters

|

High Quality Laser Cutting Bending Steel Aluminum Stainless Steel Customized Sheet Metal Fabrication

|

|

|

|

|

1.The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is lower, at least reducing the trade company's service fee.

2.we consolidate all raw material demand and bought from approved vendor at a mass quantity and right cost with fine quality,Combined with our 10 years of professional CNC machining efficient machining process design experience. Join us to reduce your costs |

|

|

Process |

Small details make big difference

1.We promise:All the parts from our company have no sharp edge. Holes and screw holes are chamfered for convenient assembly (Under no indication). Every product will be carefully packed to prevent the bump and rust in transit. 2.The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart. 3.Every operator with much experience and they have to double check program,drawing and SOP and tools before action;Operator have to run FA for qualify before mass production;Operator have to check every measure once one setup done to avoid parts scrap in the end. 4.All staff have been training about cost and quality management. Our Professional, Your Satisfaction. |

|

|

Quality |

1.Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

2.Each size of product must be tested one to one after completing production and provide quality report. 3.QC Ensure all parts are 100% inspected before shipment We control it so you don't have to worry |

|

|

Progress |

1.We are a combination of production and trade, industry and trade integration business.

2. We can understand the actual situation of our factory, we are more professional ,more reasonable and more accurate than trade company. So keep you posted on your progress every day. Keep you up to date |

|

|

|

Welcome Customized

Make you want to do what you want to be unique,Put Your Good Ideal into Reality. |

|

|

|

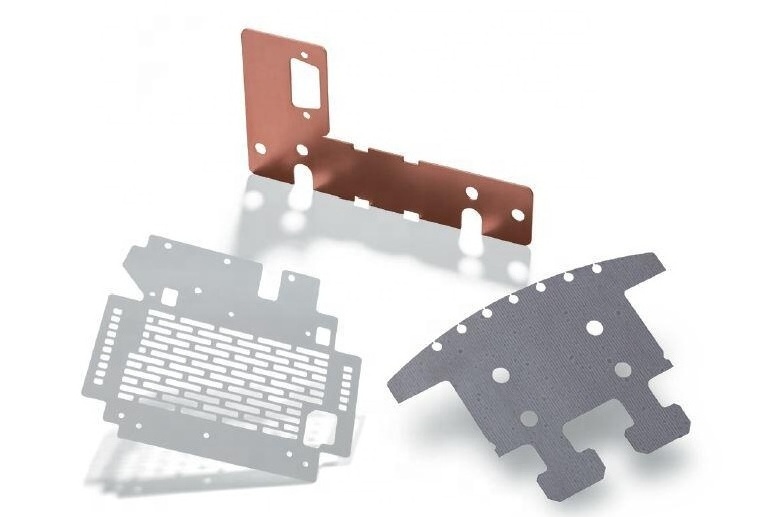

Aluminum Alloy:

5052 /6061/ 6063 /6082/ 2017 / 7075 / etc. Brass Alloy: 3602 / 2604 / H59 / H62 / etc. Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. Steel Alloy: Carbon Steel / Die Steel / Spring Steel etc. Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS /PMMA/ PP / PC / PE / PEEK / Titanium etc. We handle many other type of materials. Please contact us if your required material is not listed above. Wide Range for Your Selection. |

|

|

Surface Treatment

|

Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting According to customers' specific request.

Match Your Products.

|

|

|

|

Medical equipment, electronic equipment, communication equipment, semiconductor equipment, mechanical equipment, automation

equipment, new energy, petroleum, automobile, aviation, motorcycle, bicycle, etc |

|

|

Sample Time and Bulk Time

|

Sample Time Around 2-3 Working Days;Bulk Time Around 7-15Working Days.

|

|

|

Payment Term

|

T/T,Western Union, Cash, others can be negotiated.Only 30% Deposit

Make Your Floating Capital More Effective.

|

|

|

Shipping

|

By Air or Sea. If Choose by Air, it is Faster Like You Purchase from Local Market.

|

|

Product Description

Hot Searches