- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/Customizable

-

Place of Origin:

-

Jiangsu, China, China

-

Brand Name:

-

XiNLiLONG

-

Dimension(L*W*H):

-

7600 x 2900 x 2600MM

-

Weight:

-

3800 KG

-

Color:

-

Customizable

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Egypt

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

Quick Details

-

Packaging Type:

-

Cartons, Film

-

Packaging Material:

-

Plastic, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

220V/380V/Customizable

-

Place of Origin:

-

Jiangsu, China, China

-

Brand Name:

-

XiNLiLONG

-

Dimension(L*W*H):

-

7600 x 2900 x 2600MM

-

Weight:

-

3800 KG

-

Color:

-

Customizable

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Egypt

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

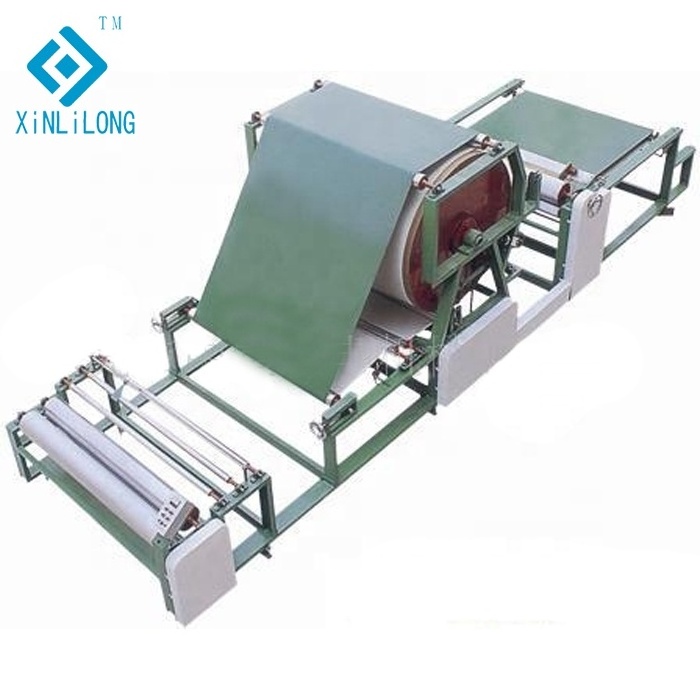

water-base glue and super glue/ double-use lamination machine

EVA fabric mesh pu artificial leather laminating machine by super glue strong glue

APPLICATION

This Laminating Foam Machine is used for:

1. Gluing material and laminating with other materials, suitable for laminating EVA, cloth, sponge, non woven fabric, plastic, leather, synthetic leather, etc.

2. Widely used in cloth, shoemaking, luggage, interior decoration, car interiors, toy and other industries.

LAMINATING MACHINE FEATURES

♦ It uses water-based glue and super glue .

♦ Improve the quality of the products greatly, save cost.

♦ Vertical structure , low breakdown rate and long service time.

♦ Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

♦ This laminating foam machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

♦ Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

♦ For clamp roller, both hand wheel adjustment and the pneumatic control are available.

♦ Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life

♦ Customized manufacturing is available.

♦ Low maintenance cost and simple to maintain

OPTION:

1. Accumulators for foam, textile, backlining, etc

2. Edge cutting device

3. Inspection machine

4. Swaying device to sway the final laminated materials into piles

5. Cutting machine

6. Conduction oil heating drying roller instead of normal heating drying roller ( When the temperature required by the materials is over 160 celcius degree.)

YouTube Video Link:

1) PUR hot melt laminating machine : https://youtu.be/gRtuq3qpbBU

2) Glue dot transfer laminating machine : https://youtu.be/fP2jh726GHw

3) Adhesive tape laminating machine : https://youtu.be/Jn2rVJd_7Z4

4) Belt laminating machine : https://youtu.be/ocwMaHwYdpk

5) Flame laminating machine : https://youtu.be/69ad4D-Yenc

6) Sandpaper laminating machine : https://youtu.be/lR4xhXPjrDI

7) Nonwoven fabric Powder Laminating Machine : https://youtu.be/0R2eylS9Egk

8) Wall cloth laminating machine : https://youtu.be/dTVesUURXkI

9) Ultrasonic embossing machine : https://youtu.be/m_78PJ_AMNM

Machine Details:

1) Effective coating width: 1000-1800mm

2) Machine door width: 2000mm (sizing roller, scraping knife, pressing roller, etc.)

3) Drying cylinder diameter: Ø800- Ø2000mm (customized)

4) Heating method: electric heating / natural gas heating / heat transfer oil heating

5) Electric heating power: about 40.5KW (the diameter of the roller is different)

6) Total power distribution capacity: about 60KW (the diameter of the roller is different)

7) Composite speed: 1-45m/mm

8) Substrate (applicable to): sponge, leather, non-woven fabric, artificial leather...

9) Coating agent: water-based glue, super glue

10) Coating method: rubber roller and scraper blade coating method

11) Power supply: 380V ± 10%, 50HZ, three-phase five-wire.

12) Machine weight: 3000kg

13) Dimensions: 7600 × 2500 × 2560mm (length x width x height)

Used For:

Parts shows:

Factory production workshop: