- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

6000*975*1700*mm

-

Weight:

-

790 KG

-

Core Components:

-

other

-

Filling speed:

-

1000-2000 bph

-

Filling accuracy:

-

About 1% (for water)

-

Machine material:

-

SUS304 or 316

-

Air consumption:

-

0.6-0.8Mpa

-

Power supply:

-

AC220V/110V, 1 phase

-

Power:

-

2KW

-

Filling material:

-

liquid&paste

-

Conveyor Speed:

-

5~25 meters/minute

-

Application Bottle Size:

-

Height: 25mm~300mm

-

Applicable label size:

-

Label Length: 20mm~290mm

Quick Details

-

Machinery Capacity:

-

4000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Glass, Wood

-

Filling Material:

-

Oil, Juice

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

6000*975*1700*mm

-

Weight:

-

790 KG

-

Core Components:

-

other

-

Filling speed:

-

1000-2000 bph

-

Filling accuracy:

-

About 1% (for water)

-

Machine material:

-

SUS304 or 316

-

Air consumption:

-

0.6-0.8Mpa

-

Power supply:

-

AC220V/110V, 1 phase

-

Power:

-

2KW

-

Filling material:

-

liquid&paste

-

Conveyor Speed:

-

5~25 meters/minute

-

Application Bottle Size:

-

Height: 25mm~300mm

-

Applicable label size:

-

Label Length: 20mm~290mm

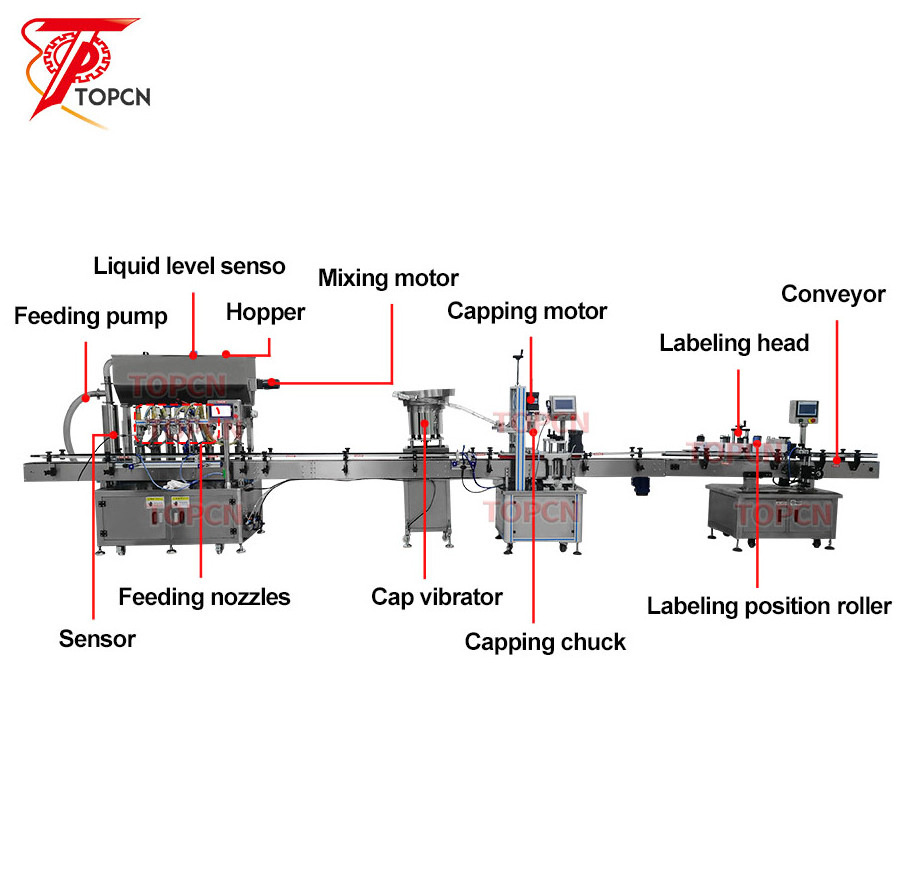

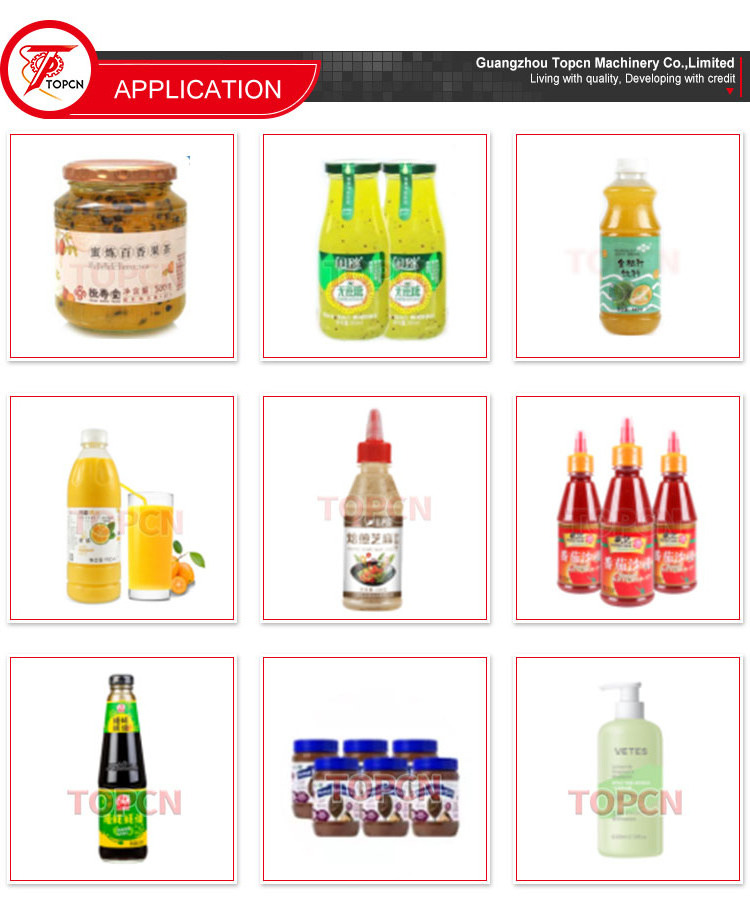

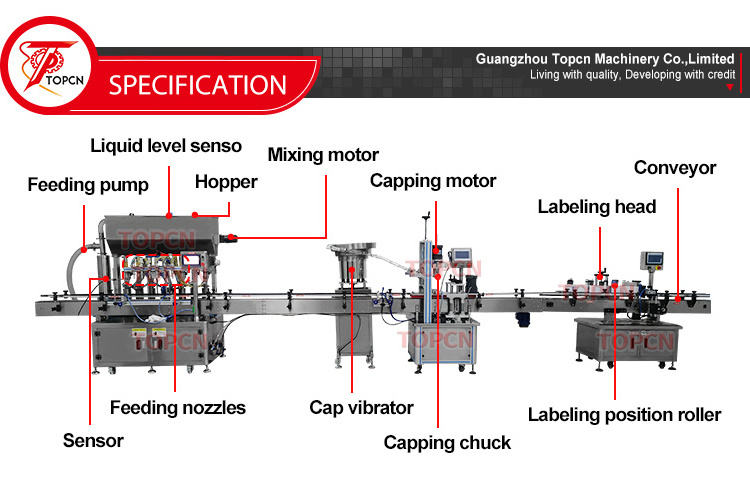

Filling Machine:

This automatic piston pump filling machine is equipped with feeding pump,this is more convenient for feeding filling

material.Different filling range can be chosen and multiple filling nozzle can be customized according to operation need.

It is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various granule-containing material, such as pulp-containing beverages, shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing.

material.Different filling range can be chosen and multiple filling nozzle can be customized according to operation need.

It is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various granule-containing material, such as pulp-containing beverages, shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing.

|

Automatic Filling Machine

|

|

|

|

|

||||

|

Voltage

|

110/220v 50-60HZ 600W

|

|

|

|

||||

|

Filling Range

|

5-60m/10-120ml/50-500ml/100-1000ml

/500-3000m/500-5000ml |

|

|

|

||||

|

Working Speed (Based On Water)

|

20- 50bottles/Min

|

|

|

|

||||

|

Mixing Speed

|

About 0-80r/min(adjustable)

|

|

|

|

||||

|

Filling Accuracy

|

≤+1%

|

|

|

|

||||

|

Air Pressure

|

0.5-0.7mpa

|

|

|

|

||||

|

Conveyor Size

|

About 2000*114mm

|

|

|

|

||||

|

Size Of Filling Nozzle

|

Φ8-10mm

|

|

|

|

||||

|

Size Of Air Compressor Connector

|

Φ8mm

|

|

|

|

||||

|

Machine Weight

|

329kg

|

|

|

|

||||

|

Machine Size

|

2010*975*1700*mm

|

|

|

|

||||

|

Package Weight

|

392kg

|

|

|

|

||||

|

Package Size

|

2130**1130*1830mm

|

|

|

|

||||

|

Automatic Capping Machine

|

|

|

|

|

||||

|

Bottle height

|

30-300mm

|

|

|

|

||||

|

Cap Diameter

|

18-70mm

|

|

|

|

||||

|

Bottle Diameter

|

20-160mm

|

|

|

|

||||

|

Working speed

|

20-60 bottles/minute

(depending on bottle and cap size and shape) |

|

|

|

||||

|

Working voltage

|

AC220V/110V 50-60HZ

|

|

|

|

||||

|

Working pressure

|

0.4-0.6 MPa

|

|

|

|

||||

|

Size Of air compressor connector

|

OD 8mm

|

|

|

|

||||

|

Dimension

|

About 1930*740*1600mm

|

|

|

|

||||

|

Packing size

|

About 2000*820*1760mm

|

|

|

|

||||

|

Net weight/Gross weight

|

About 113kg/192.5kg

|

|

|

|

||||

|

Gross weight

|

About 284kg

|

|

|

|

||||

|

Automatic Labeling Machine

|

|

|

|

|

||||

|

Labeling Precision

|

±1mm (excluding product and label error);

|

|

|

|

||||

|

Power Supply

|

AC220V 50/60Hz 700W

|

|

|

|

||||

|

Conveyor Speed

|

5~25 meters/minute;

|

|

|

|

||||

|

Labeling Speed

|

10~35pcs/min(Related to product, label size);

|

|

|

|

||||

|

Sticker Out-Come Speed

|

Stepping Motor: 5~19 meters/minute

|

|

|

|

||||

|

|

Servo Motor: 5~25 meters/minute

|

|

|

|

||||

|

Application Bottle Size

|

External diameter: Φ25-100mm;

|

|

|

|

||||

|

|

Height: 25mm~300mm;

|

|

|

|

||||

|

Applicable label size

|

Label Length: 20mm~290mm;

|

|

|

|

||||

|

|

Label Width(body paper width): 20mm~120mm; 180mm (option)

|

|

|

|

||||

|

Inner dia. of paper roll

|

Φ76mm

|

|

|

|

||||

|

External dia. of paper roll

|

Max. Φ300mm

|

|

|

|

||||

|

Size (LXWXH)

|

2000mm×1150mm×1600mm

|

|

|

|

||||

|

Weight

|

185kgs

|

|

|

|

||||

|

Attention: Non-standard Labeling System

The price shown on Alibaba system has no reference value. All final quotation based on your exact products details and requirements. |

|

|

|

|

||||

|

Labeling Machine Electric Parts

|

|

|

|

|

||||

|

Name

|

Origin

|

Brand

|

|

|

||||

|

Motor

|

Japan

|

ZD

|

|

|

||||

|

Frequency converter

|

China

|

Coreken

|

|

|

||||

|

Air cyliner

|

Taiwan, China

|

AirTac

|

|

|

||||

|

Touch screen

|

Germany

|

SIEMENS

|

|

|

||||

|

PLC

|

Japan

|

Mitsubishi

|

|

|

||||

|

Label sensor

|

Germany

|

Sick

|

|

|

||||

|

Bottle sensor

|

Japan

|

Keyence

|

|

|

||||

Anti-dripping piston filling nozzles

The nozzles of Juice Filling Machine Production Line can be adjusted according to bottle size,multiple filling nozzle can be customized according to production need.Multiple filling nozzles can help you improve production efficiency greatly.

Feeding pump

Bottle juice filling machine equipped with piston feeding pump,it can feed filling material automatically and no need to pour material into tank.This helps to save production labor and improve production efficiency.

Liquid level device and feeding pump

Juice Filling Machine with liquid level sensor in hopper, when the sensor detect material below the level,

piston feeding pump will feed filling material automatically and no need to pour material into tank.

This machine is with mixing function(heating function can customize),mixing speed can be adjusted according to the regulator.This is good for filling jam,face cream,chocolate etc,The hopper can hold 120L material .

With bottle cap feeder which can feed lids before capping bottle.This one needs to be customized according to cap size.

Rubber material is soft with elasticity to ensure that the device won't broke the caps when capping. There is the capping device to fox the cap to make sure it won't deviate

The cap range is 20-70mm(can customize to 100mm)

Multi angle adjustment base, convenient for customers to adjust different bottles and labels, higher labeling precision

Related Products

Full Automatic Production Line

* Can automatically

filling liquid

, capping bottle caps and labeling stickers at the same time.

* With conveyor, it can help to save a lot of labor.

■

1. A step-by-step free English manual and operation video to easily know how to operate the machine.

■

2. Our senior engineers are skillful and fluent in English. They have rich oversea experiences and are available to oversea services. Below with some pictures our engineers trained customers how to install and operate the machines.

Guangzhou TOPCN Machinery CO.,Limited

is a professional manufacturer and exporter that is concerned with the design development and production of mixing tank, storage tank, vacuum homogenizer, filling machine, capping machine, labeling machine, perfume machine, automatic packaging machine, aluminum foil sealing machine, shrink packaging machine, sealing machine, vacuum packing machine, strapping machine, marking equipment etc.

Our head office located in

GUANGZHOU CITY,

we have factory in

Yazhou, Wenzhou

and

Shanghai.

We with an advantageously geographical location and convenient transportation. We boast state-of-the-art automatic production lines, domestically advanced production technologies and complete testing equipment and quality systems. It gives us a broad development space. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

FAQ

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke, how to solve the problem?

A7: Yes, we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke, how to solve the problem?

A8: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q9: Do you have manual or operation video for us to know more about the machine?

A9: Yes, we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke, how to solve the problem?

A10: Yes, we will send you the manual and operation video after you ask for us.

Q11: If there's some spare parts that broke, how to solve the problem?

A11: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Hot Searches