- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan

-

Brand Name:

-

JOCONN

-

Dimension(L*W*H):

-

9500*2200*2800

-

Weight:

-

250 KG

-

Product name:

-

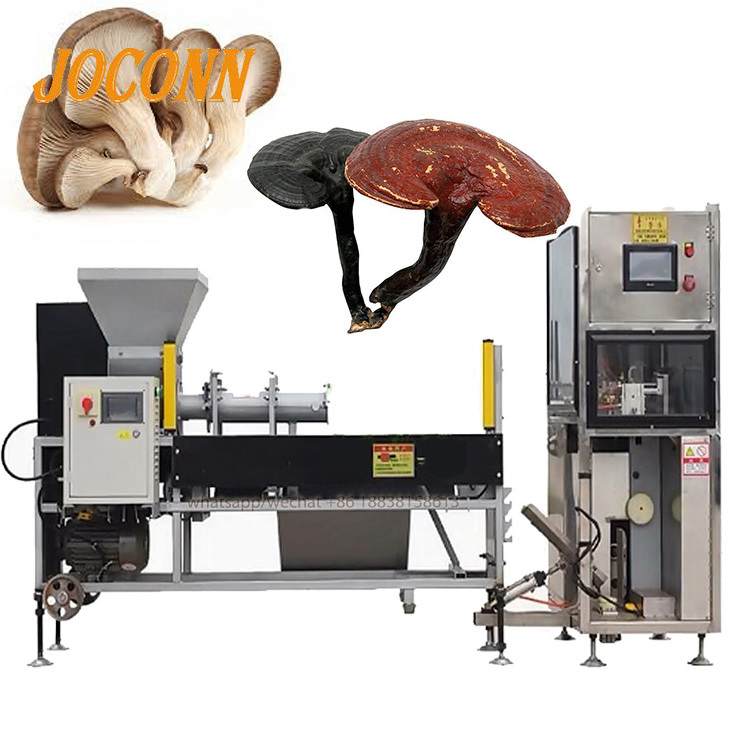

edible fungi bagging binding machine production line

-

Function:

-

mushroom filling and typing

-

After-sales Service Provided:

-

Video Technical Support ,Online Support

-

Keywords:

-

Automatic mushroom filling binding machine

-

Processing Types:

-

Raw Material bagging - typing machine

-

Feature:

-

High Efficiency

-

Advantage:

-

Automatic Working Support Customization

-

Suitable for:

-

oyster mushrooms,shiitake mushrooms,enoki mushrooms, morels etc

-

Marketing Type:

-

New Product 2022

Quick Details

-

Machinery Capacity:

-

1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Other

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan

-

Brand Name:

-

JOCONN

-

Dimension(L*W*H):

-

9500*2200*2800

-

Weight:

-

250 KG

-

Product name:

-

edible fungi bagging binding machine production line

-

Function:

-

mushroom filling and typing

-

After-sales Service Provided:

-

Video Technical Support ,Online Support

-

Keywords:

-

Automatic mushroom filling binding machine

-

Processing Types:

-

Raw Material bagging - typing machine

-

Feature:

-

High Efficiency

-

Advantage:

-

Automatic Working Support Customization

-

Suitable for:

-

oyster mushrooms,shiitake mushrooms,enoki mushrooms, morels etc

-

Marketing Type:

-

New Product 2022

Automatic edible fungus bagging binding machine production line/Leading oyster mushroom spawn sack bag filling tying equipment

This new type edible fungus cultivation production line is an advanced and automatic equipment integrating the functions of mushroom bagging and binding ,it can complete the entire procedure efficiently and greatly increase the output ,avoid wasting raw materials, suitable for long bag operations and widely used in a variety of edible fungus cultivation ,such as oyster mushrooms and shiitake mushrooms,e noki mushrooms, morels, ganoderma etc.

|

Features of E dible Fungi Bag Filling and Binding Machine

|

|

|

1 |

The fuselage adopts high-quality material with high precision, wear resistance, corrosion resistance and high finish. |

|

2 |

Spiral feeding structure, high efficiency, low labor intensity, saving time and labour. |

|

3 |

Equipped with electrical equipment, which has good stability, high reliability and durability. |

|

4 |

You can replace the matching sleeve auger according to your different production needs. |

|

5 |

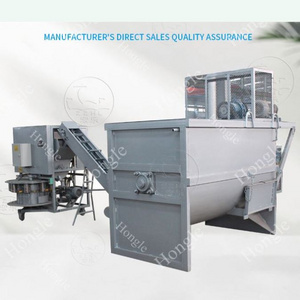

If this mushroom bag packing and sealing machine production line matches the feeding hoist, mixer, conveyor etc, the whole working process can be fully automated and intelligent.

|

|

Model |

Input Power |

Production efficiency |

Weight |

Dimensions |

|

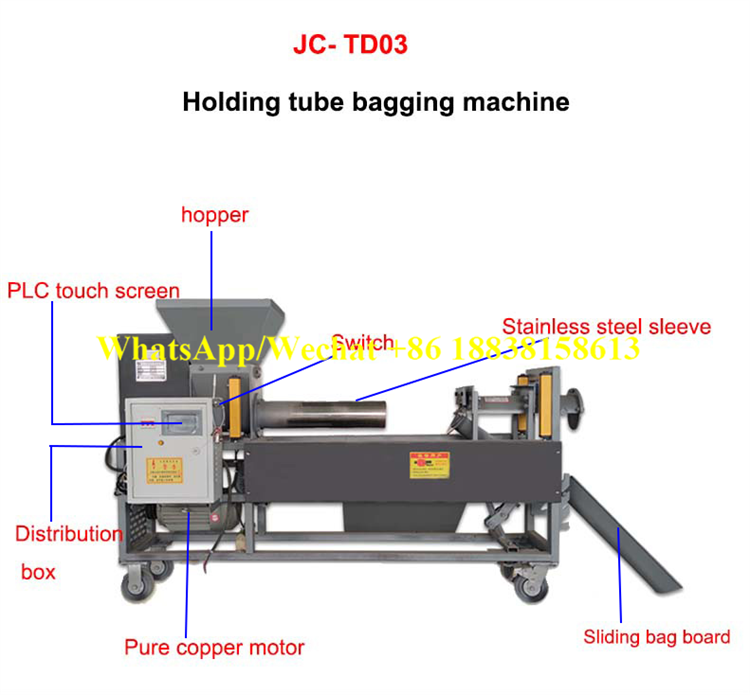

JC -TD03 |

380V/3KW |

1000 bags/hour |

150kg |

1700×460×1050mm |

|

Performance |

This fully automatic mushroom bagging machine is composed of holding tube auger combination, PLC touch screen intelligent program control, one-button operation, automatic bagging, intelligent detection, fault alarm, digital display control, which has good property and high efficiency. |

|||

|

Model |

Input Power |

Production efficiency |

Weight |

Dimensions |

|

JC -ZK03 |

220V/150W |

≥800 bags/hour |

100kg |

600×460×1150mm |

|

Performance |

This automatic binding machine adopts numerical control program, pneumatic component control, intelligent detection, intelligent tying, and intelligent bag output at one time, which greatly saves labor. It can be combined with bagging machines for continuous use, also could choose touch screen control to match the production line. |

|||

JC - TD03

Automatic holding tube fungus bag filling machine

JC - ZK03

Mushroom automatic binding machine

Automatic edible fungus bagging and binding machine production line

Related consumables

If you are interested or have any questions , please feel free to contact me by namecard below , or scan the QR code for quick talk on wechat .we are on service 24hrs .