- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/50hz

-

Power:

-

70

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

2.0*1.5*2.2

-

Year:

-

2024

-

Application:

-

Food Processing Machine

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Capacity:

-

100-800kg/h

-

Certification:

-

ISO9001

-

Advantage:

-

Cost-effective

-

Power Source:

-

Electric Power

-

Motor:

-

Siemens ABB

-

Inverter:

-

DELTA

-

Suitable for:

-

packing

Quick Details

-

Marketing Type:

-

New Product 2029-2023-2024-2025

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sunward

-

Voltage:

-

380v/50hz

-

Power:

-

70

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

2.0*1.5*2.2

-

Year:

-

2024

-

Application:

-

Food Processing Machine

-

Function:

-

Multifunctional

-

Material:

-

304 Stainless Steel

-

Capacity:

-

100-800kg/h

-

Certification:

-

ISO9001

-

Advantage:

-

Cost-effective

-

Power Source:

-

Electric Power

-

Motor:

-

Siemens ABB

-

Inverter:

-

DELTA

-

Suitable for:

-

packing

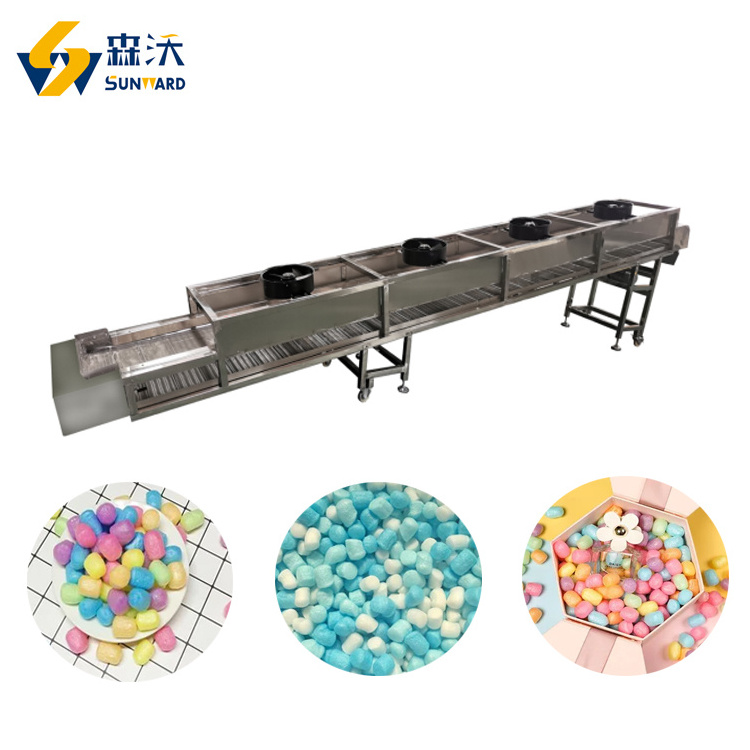

Fully Automatic Degradable Packing Peanuts Production Line

Packaging bubble peanut making machine uses corn starch, cassava starch, potato starch cosrice, corn, beans and all kinds of grains as raw materials. Through extruding,inflating,dryin it could produce many kinds of degradable packing filling pellet material.

1. Capacity: 100-800kg/h

2.Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'local voltage according to different countries.

3. Raw Materials: C orn Starch, Covassa Starch, Rice/Corn/Beans and all kinds of grains.

4. Technical Parameter:

| Model | TSE65-III | TSE70 | TSE85 | TSE95 |

| Installed Power | 70kw | 105kw | 150kw | 120kw |

| Power Consumption | 50kw | 75kw | 100kw | 95kw |

| Capacity | 100-150kg/h | 200-260kg/h | 300-500kg/h | 600-800kg/h |

| Dimension(m) | 1.7*1.3*2.0 | 2.0*1.5*2.2 | 3.0*1.5*2.6 | 3.0*1.5*2.6 |

5. Flow chart: Mixer→Screw conveyor→Twin screw extruder→Air conveyor→Dryer→Cooling

Capacity: 40k/batch

Power: 4.0 kw

Consumption:3kw/h

Diameter : 600mm

Dimension(m): 1. 0 3×0.7 2 ×1.3 5

Mixing Time: 2minutes-3minutes/batch

Stainless steel and mild steel construction. The raw material is mixed with water or other liquid additives. The discharge hole adopts the new handle-opened design, safe and sealed well.

Tube size:114mm

Power(KW): 0.75

Consumption: 0.5kw/h

Dimension(m): 3. 3 ×0. 8 ×2. 3

Capacity:100-500kg/h

Screw conveyor is used to convey mixed flour into feeder on extruder; there is wheel on screw conveyor, easy to move.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5. Self-cleaning , when stopping, it can be cleaned without disassembling.

Baking and drying the food. All kinds of the inflating food, pet food, TVP food, peanut, nut, chew nut can be dried.

The dryer has the compact structure, small occupying, large drying area, small surface area, slight radiating heat and high thermal efficiency. The belt and the heat preservation use the stainless steel; it is suitable for food industry. The running speed of belt net can be controlled (frequency). The temperature can be controlled willfully and designed according to the need. Material touching the food is stainless steel, bracket is iron with paint.