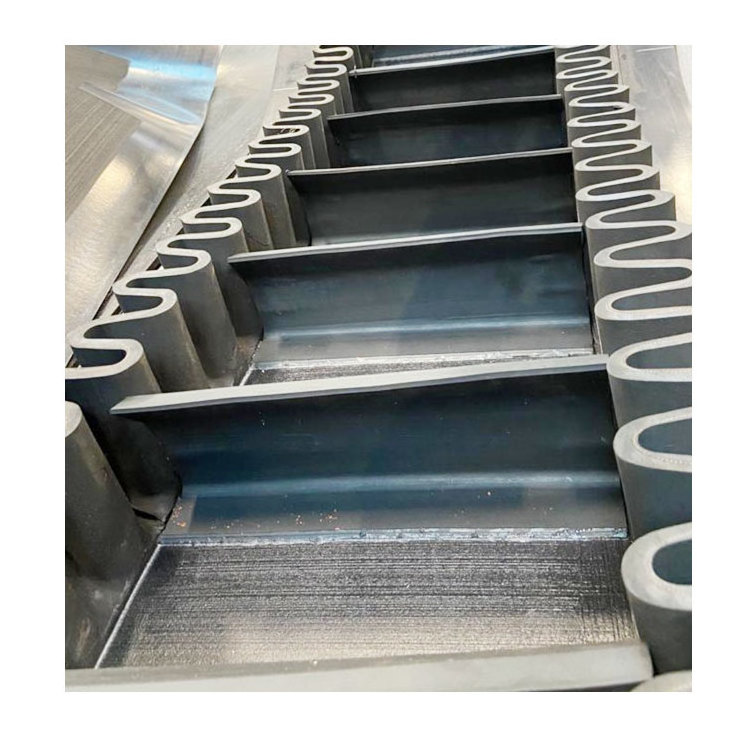

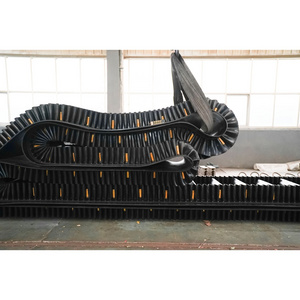

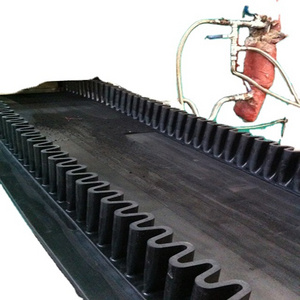

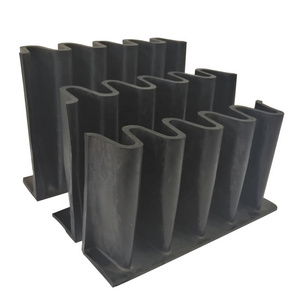

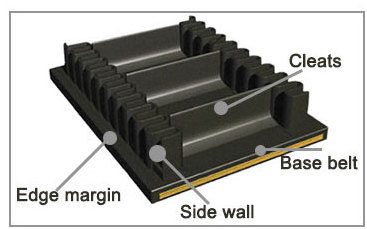

The big dip angle corrugated sidewall belt is mainly composed by base belt, sidewall and cleats. The sidewall is mainly for preventing materials from sliding and scattering.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

R-ECB

-

Color:

-

Black,green

-

Material:

-

Rubber+EP Fabric

-

Thickness:

-

Custom

-

Width:

-

Custom

-

Length:

-

custom

-

Service:

-

Full-process Service

-

Application:

-

Transport Materials

-

Cleat type:

-

t/ts/tc/tcs

-

Material Feature:

-

Heat Resistant

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rentone

-

Model Number:

-

R-ECB

-

Color:

-

Black,green

-

Material:

-

Rubber+EP Fabric

-

Thickness:

-

Custom

-

Width:

-

Custom

-

Length:

-

custom

-

Service:

-

Full-process Service

-

Application:

-

Transport Materials

-

Cleat type:

-

t/ts/tc/tcs

-

Material Feature:

-

Heat Resistant

rubber conveyor sidewall belt

Product Description

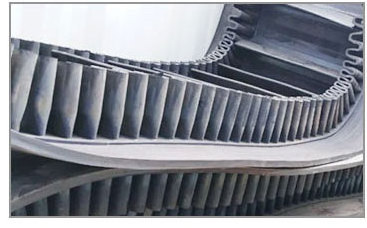

Our sidewall conveyor belt can realize the high-volume and steep-angle delivery of materials in limited space. It is composed of three parts, namely base belt, sidewall and cleat. The sidewall with its unique design can keep materials from sliding down. To facilitate bypassing the roller, the sidewall is corrugated and can endure high pressure and repeated bending. The cleat, with a large carrying capacity and dip angle, is the main part of conveying materials. In order to achieve large-angel delivery, T-style and TC-style are adopted. The sidewall and cleat are connected to the base belt through secondary vulcanization, showing high joint strength. The reinforced inner wall, combining flexibility and strength, can effectively avoid tearing. Our sidewall conveyor belts are mainly applied to convey granular or liquid material. The conveyor belt with sidewalls possesses many features such as heat resistance, abrasion resistance, fire prevention, low-temperature resistance, oil resistance, skid resistance and alkali resistance. Before leaving our sidewall conveyor belt factory, our products are tested for tensile strength, anti-abrasion and adhesion, thus meeting the requirements of clients.

|

Based Belt Width(B)

|

Sidewall Height(H)

|

Cleat Height(Hl)

|

Bottom Width of

|

Cleat Width(B2)

|

Empty Width(B3)

|

|

300

|

40

|

35

|

25

|

180

|

35

|

|

|

60

|

55

|

50

|

120

|

40

|

|

|

80

|

75

|

|

|

|

|

400

|

60

|

55

|

50

|

180

|

60

|

|

|

80

|

75

|

|

|

|

|

|

100

|

90

|

|

|

|

|

500

|

80

|

75

|

50

|

250

|

75

|

|

|

100

|

90

|

|

|

|

|

|

120

|

10

|

|

|

|

|

650

|

100

|

90

|

50

|

350

|

100

|

|

|

120

|

10

|

|

|

|

|

|

160

|

140

|

75

|

300

|

|

|

800

|

120

|

110

|

50

|

460

|

120

|

|

|

160

|

140

|

75

|

410

|

|

|

|

200

|

180

|

|

|

|

|

1000

|

160

|

140

|

75

|

550

|

150

|

|

|

200

|

180

|

|

|

|

|

|

240

|

220

|

|

|

|

|

1200

|

160

|

140

|

75

|

690

|

180

|

|

|

200

|

180

|

|

|

|

|

|

240

|

220

|

|

|

|

|

|

300

|

260

|

100

|

640

|

|

|

1400

|

200

|

180

|

75

|

830

|

210

|

|

|

240

|

220

|

|

|

|

|

|

300

|

260

|

100

|

780

|

|

|

|

400

|

360

|

|

|

|

|

Cleat Type

|

Cleat Height(mm)

|

Bottom Width(mm)

|

Weight(kg/m)

|

Min.Drum Diameter

(mm) |

Production Length(m)

|

|

t

|

20

|

40

|

0.28

|

75

|

3/5

|

|

|

25

|

40

|

0.3

|

75

|

3/5

|

|

|

35

|

55

|

0.55

|

100

|

3/5

|

|

|

40

|

70

|

0.6

|

125

|

3/5

|

|

|

55

|

80

|

1.45

|

125

|

3/5

|

|

|

75

|

80

|

1.8

|

150

|

3/5

|

|

|

90

|

110

|

2.5

|

250

|

3/5

|

|

|

110

|

110

|

2.8

|

315

|

3/5

|

|

|

140

|

160

|

6.6

|

400

|

2.5

|

|

|

180

|

160

|

8.3

|

500

|

2.5

|

|

|

230

|

175

|

10.46

|

630

|

2.5

|

|

ts

|

110

|

160

|

7.9

|

315

|

3

|

|

|

140

|

160

|

9.25

|

400

|

3

|

|

|

180

|

160

|

11.5

|

500

|

3

|

|

|

230

|

160

|

13.5

|

630

|

3

|

|

|

250

|

160

|

14.6

|

630

|

3

|

|

|

280

|

160

|

17.65

|

800

|

3

|

|

|

360

|

160

|

19.25

|

1000

|

3

|

|

tc

|

75

|

80

|

1.8

|

150

|

3/5

|

|

|

90

|

110

|

2.5

|

250

|

3/5

|

|

|

110

|

110

|

2.8

|

315

|

3/5

|

|

|

140

|

160

|

6.6

|

400

|

2.5

|

|

|

180

|

160

|

8.3

|

500

|

2.5

|

|

|

230

|

175

|

10.46

|

630

|

2.5

|

|

tcs

|

110

|

160

|

7.9

|

315

|

3

|

|

|

140

|

160

|

9.25

|

400

|

3

|

|

|

180

|

160

|

11.5

|

500

|

3

|

|

|

230

|

160

|

13.5

|

630

|

3

|

|

|

250

|

160

|

14.6

|

630

|

3

|

|

|

280

|

160

|

17.65

|

800

|

3

|

|

|

360

|

160

|

19.25

|

1000

|

3

|

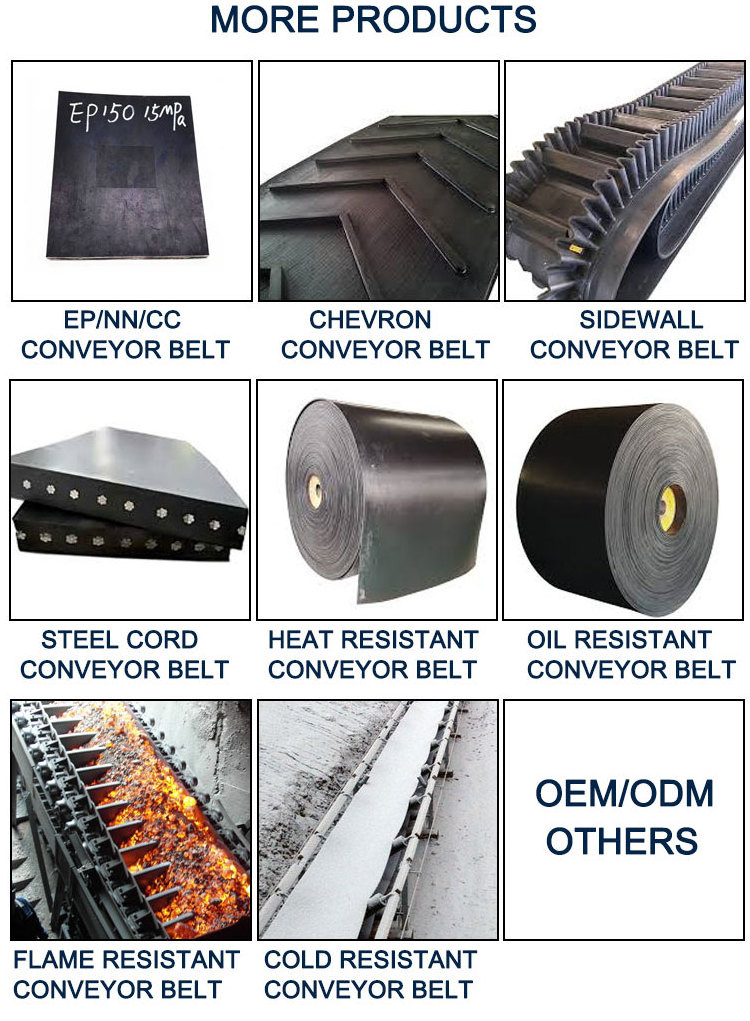

Features and Benefits

Low elongation

Long using period

Fire resistant

Able to endure low and high temperatures

Unique design

Oil-proof

Resistant to alkali

Simple structure

High delivery capacity

Qingdao Rentone Rubber Co.,Itd. is one of the most professional rubber hose manufacturers in China. It was founded in 2000 with a registered capital of RMB 50 million yuan.After years of development, we have become a leading rubber hose company in manufacturing, research and development, and sales. Our products have been exported to over 30 countries and won a high reputation, so that we can establish long-term business relationships with global customers. We are always in pursuit to be experts in the rubber hose industry and a service provider of rubber hose solutions.

Our main products include: high-pressure wire braided hoses, high-pressure and ultra high pressure wire spiral hoses, fibre braided hoses, gas hoses, oil-resistant hoses, air hoses, acid and alkali resistant hoses, PVC hoses, auto rubber hoses, hose fittings and couplings, and various types of hoses can be customized according to customer requirements. The products are featured with high and low pressure resistance, high temperature resistance, oil resistance, flexibility, good impulse performance, and long service life. Therefore, they are extensively used in construction machinery, mining, petrochemical, metallurgical casting, oil drilling, transportation, and shipbuilding industries.

FAQ

1.Q:Are you a manufacturer or a trading company?

A:We are a professional manufacturer with 20 years of industry experience

2.Q:What about the lead time?

A:2--3 days for sample 15--30 days for mass production. If urgent,we have green channel.

3.Q:Do you have any MOQ limit for conveyor belt order?

A: Low MOQ, 1pc for sample checking is available

4.Q: What are the advantages compared with other suppliers?

A: Rentonebelt has used twelve vulcanizing lines, seven mixing lines and five four-wheel calendering lines. To guarantee the quality of products, our rubber conveyor belt factory uses multifaceted product testing to eliminate possible errors and unsafe factors.

5.Q: Do you have pre-sale service?

A: Of course, we have three engineers at the same time to serve you, can help you choose the most suitable conveyor belt for you, you can also visit our production base, we welcome you very much

Hot Searches