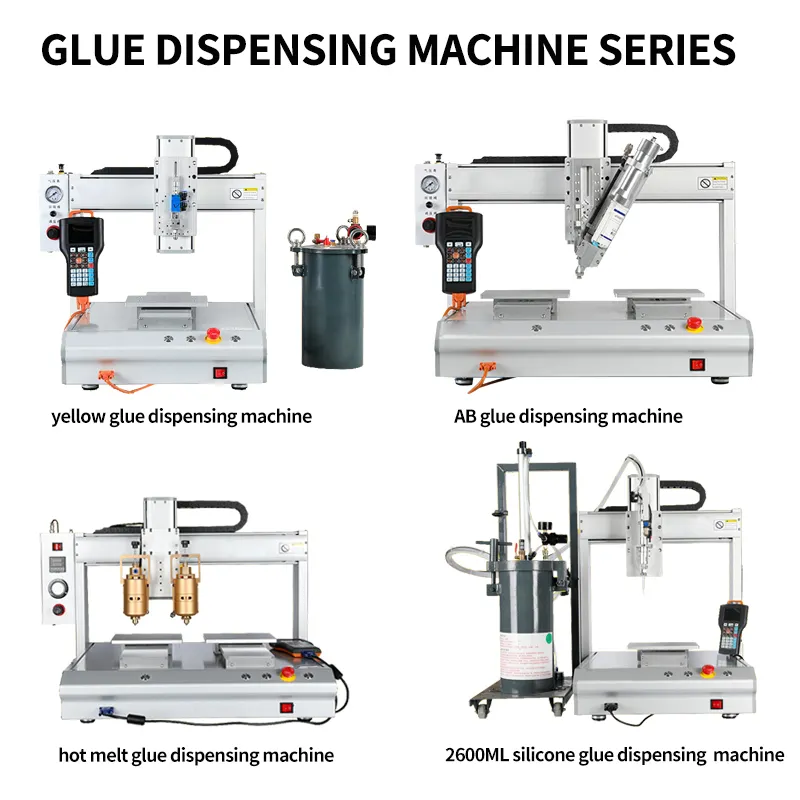

- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Consulting service

-

Product Name:

-

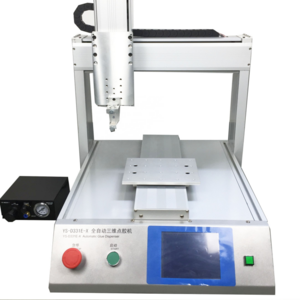

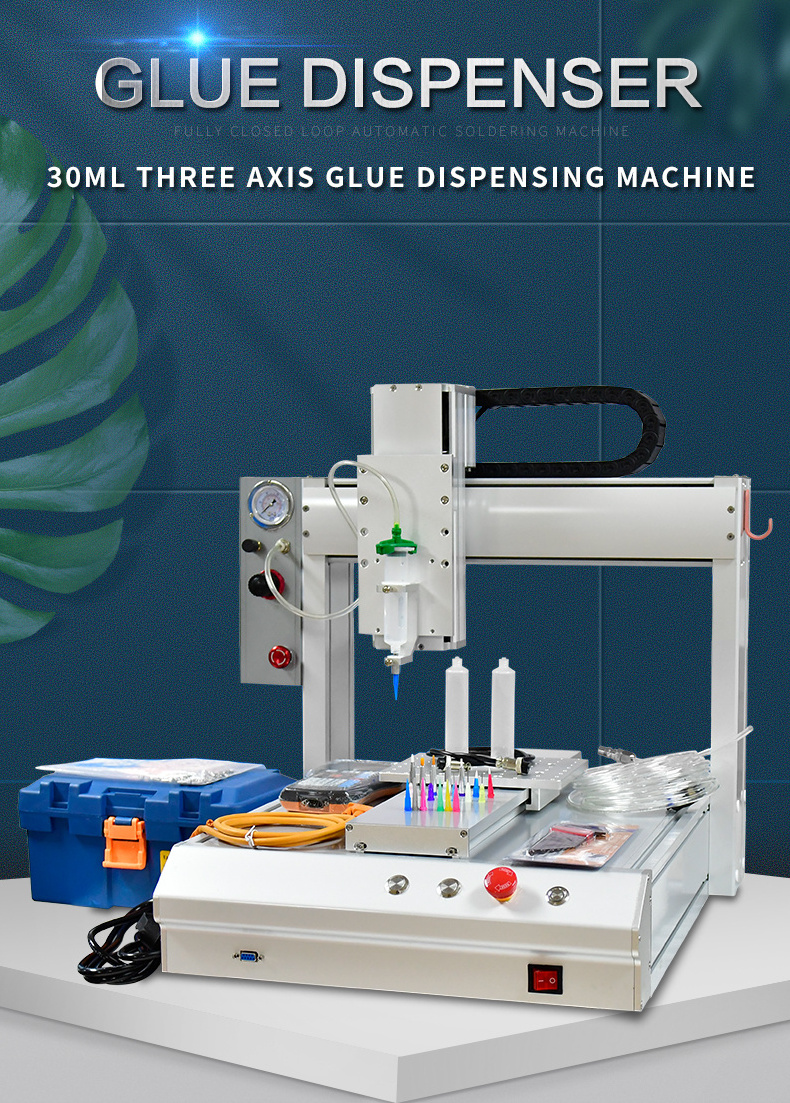

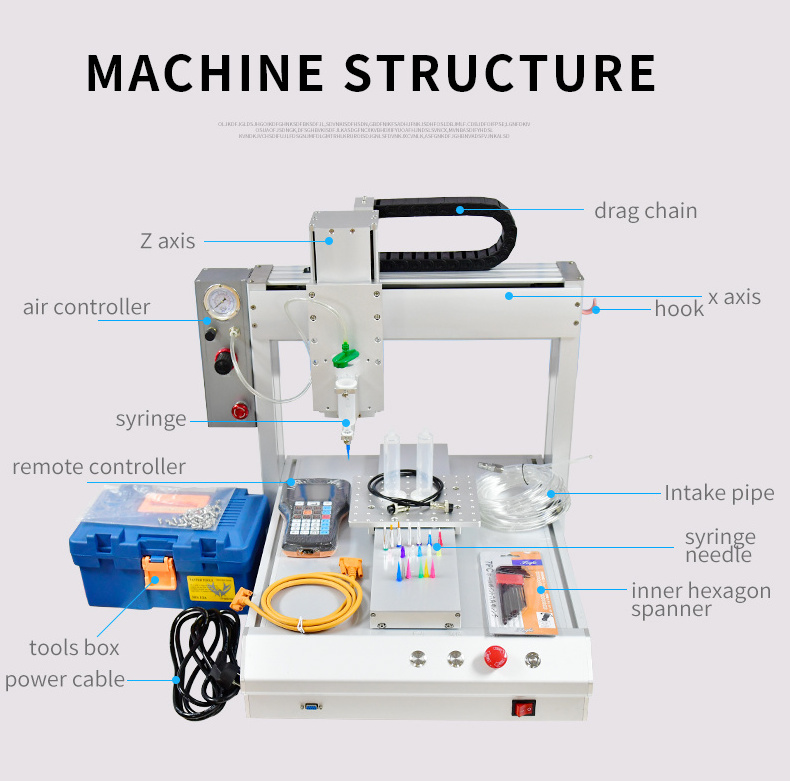

Automatic Glue Dispensing machine

-

Glue spitting time adjustment:

-

0.1 second

-

Axis tralve:

-

X/Y/Z 400*400*100mm

-

Weight:

-

45kg

-

Power supply:

-

AC220V 50/60Hz 380W

-

Material:

-

Aluminium Alloy

Quick Details

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

JULI AUTO, JULI AUTO

-

Weight (KG):

-

70

-

Core Components:

-

Consulting service

-

Product Name:

-

Automatic Glue Dispensing machine

-

Glue spitting time adjustment:

-

0.1 second

-

Axis tralve:

-

X/Y/Z 400*400*100mm

-

Weight:

-

45kg

-

Power supply:

-

AC220V 50/60Hz 380W

-

Material:

-

Aluminium Alloy

Product Description

|

一、Parameter:

|

|

|

|

|

|

|

|

|||||||

|

Model

|

|

JL-D221

|

JL-D331

|

JL-D441

|

JL-D551

|

JL-D4331

|

JL-D5331

|

|||||||

|

Number of controlled axes

|

|

Three-axis

|

|

|

|

Four-axis

|

|

|||||||

|

Effective travel

|

X axis

|

200mm

|

300mm

|

400mm

|

500mm

|

400mm

|

500mm

|

|||||||

|

|

Y1 axis

|

200mm

|

300mm

|

400mm

|

500mm

|

300mm

|

300mm

|

|||||||

|

|

Y2 axis

|

|

|

|

|

300mm

|

300mm

|

|||||||

|

|

Z axis

|

50mm

|

100mm

|

100mm

|

100mm

|

100mm

|

100mm

|

|||||||

|

Transmission mode

|

Double-track timing belt

|

|

|

|

|

|

|

|||||||

|

Power source

|

Stepper motor

|

|

|

|

|

|

|

|||||||

|

Top speed

|

500mm/sec

|

|

|

|

|

|

|

|||||||

|

Repeat accuracy

|

±0.05mm

|

|

|

|

|

|

|

|||||||

|

Maximum load

|

X/Y/Z 5kg/5kg/2kg

|

|

|

|

|

|

|

|||||||

|

Control System

|

Hand-held three-axis control system

|

|

|

|

|

|

|

|||||||

|

File storage space

|

400 sets of processing files, up to 9999 points in a single file.

|

|

|

|

|

|

|

|||||||

|

Power

|

AC110-250V 50-60HZ 350W

|

|

|

|

|

|

|

|||||||

|

Size

|

L

|

475mm

|

520mm

|

620mm

|

720mm

|

620mm

|

720mm

|

|||||||

|

|

W

|

410mm

|

585mm

|

685mm

|

785mm

|

585mm

|

585mm

|

|||||||

|

|

H

|

522.5mm

|

596.5mm

|

596.5mm

|

596.5mm

|

596.5mm

|

596.5mm

|

|||||||

|

Weight

|

|

35kg

|

44kg

|

59kg

|

65kg

|

63kg

|

62kg

|

|||||||

|

二、Main accessories:

|

|

|

|

|

|

|

|

|||||||

|

1

|

motor

|

|

|

Stepper motor

|

|

|

|

|||||||

|

2

|

Drive

|

|

|

YAKO (China)

|

|

|

|

|||||||

|

3

|

Linear Guides

|

|

|

Shangyin (Taiwan) X / Y axis dual rail, Z axis single rail

|

|

|

|

|||||||

|

4

|

Three-axis control system

|

|

|

Quanzhi (China)

|

|

|

|

|||||||

|

5

|

Power supply

|

|

|

Ming Wei (China)

|

|

|

|

|||||||

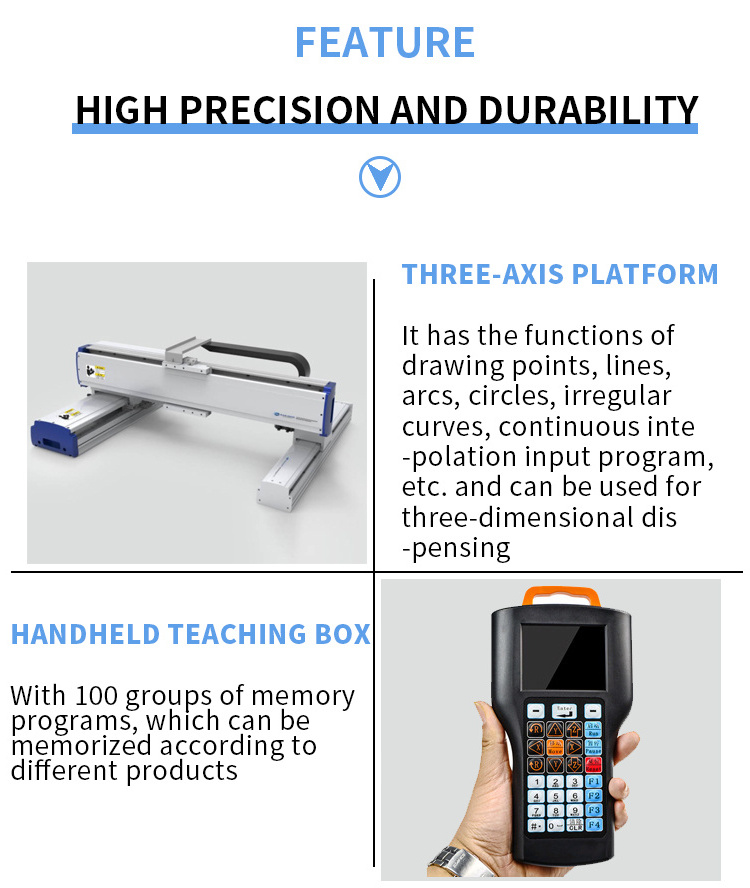

1. Can replace manual operation by high precision programming of dots, strips, arcs and patterns on different planes or curved surface.

2. Suitable for positioning of different jobs.

3. It supports graphics importing from computer, PLT files, TCF files and G code files.

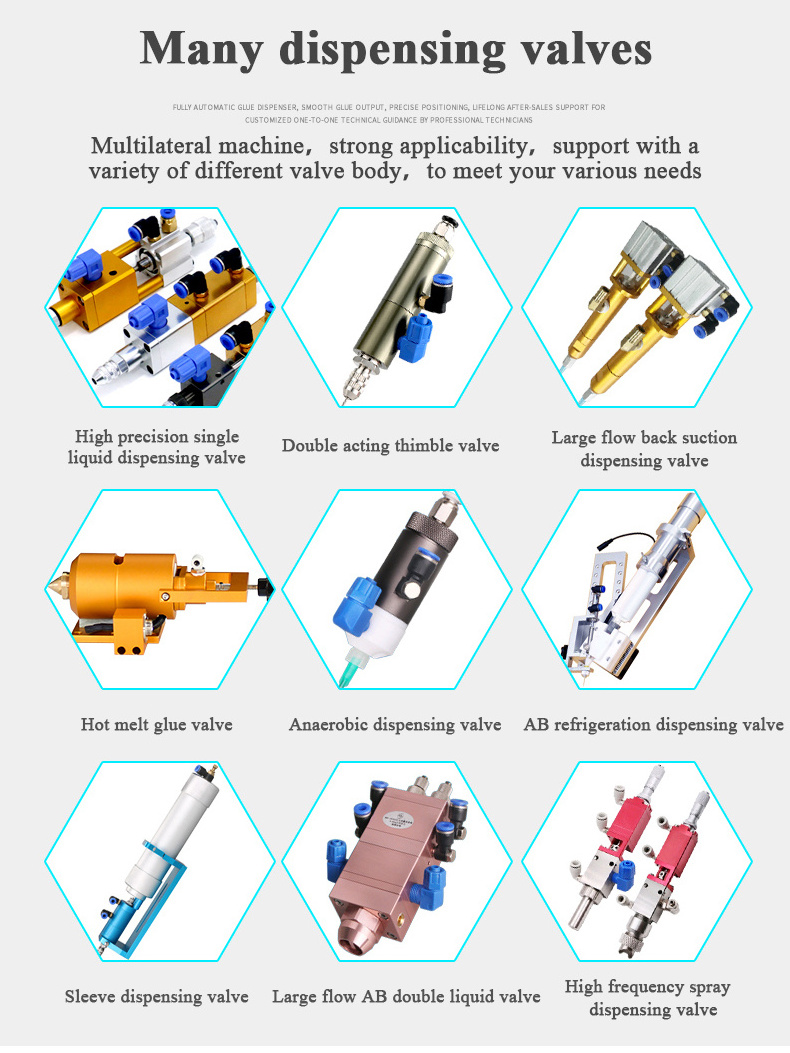

4. Suitable for glue: Anaerobics, Coatings, Cyanoacrylates, White Glues, Epoxy Resin, Greases, Sealants, Silicones, Solder/Braze Pastes, Thermal Grease, Conductive Adhesive, Red Gum, UV Glue, AB Glue, Polyurethane Resin Adhesive, etc.

2. Suitable for positioning of different jobs.

3. It supports graphics importing from computer, PLT files, TCF files and G code files.

4. Suitable for glue: Anaerobics, Coatings, Cyanoacrylates, White Glues, Epoxy Resin, Greases, Sealants, Silicones, Solder/Braze Pastes, Thermal Grease, Conductive Adhesive, Red Gum, UV Glue, AB Glue, Polyurethane Resin Adhesive, etc.

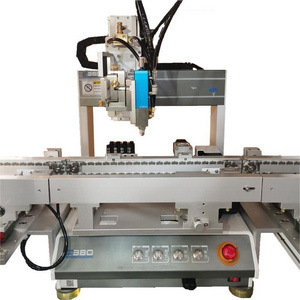

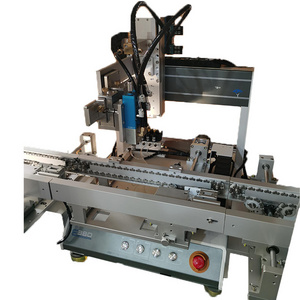

This equipment is suitable for high efficiency, high running precision and production process of dispensing. Generally suitable for products with sensors, relays, power adapters, electronic toys, sounders, electronic components, household

appliances, electric vehicle controllers, computer digital products, crafts, mobile phone boards, coil products, button products,battery boxes, speakers Dot glue bonding; speaker packaging and dispensing, optical semiconductor, mobile phone battery, laptop battery packaging, PCB board bonding, COB, IC, PDA, LCD sealing, IC packaging, IC bonding, chassis bonding, Optical device processing, hardware parts package coating, quantitative liquid filling, chip bonding, automotive mechanical parts coating,mechanical seals, etc.

appliances, electric vehicle controllers, computer digital products, crafts, mobile phone boards, coil products, button products,battery boxes, speakers Dot glue bonding; speaker packaging and dispensing, optical semiconductor, mobile phone battery, laptop battery packaging, PCB board bonding, COB, IC, PDA, LCD sealing, IC packaging, IC bonding, chassis bonding, Optical device processing, hardware parts package coating, quantitative liquid filling, chip bonding, automotive mechanical parts coating,mechanical seals, etc.

Customer praise

Recommend Products

Company Introduction

Certifications

FAQ

1. Why choose us?

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine. Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine. Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

Hot Searches