- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fenqiang

-

Model Number:

-

urea 60-100

-

Use:

-

Mass finishing polishing

-

Product name:

-

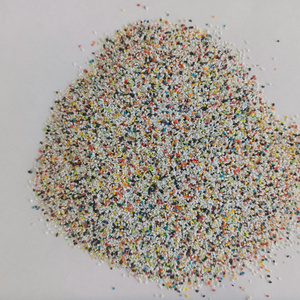

plastic media

-

Application:

-

Polishing Workpiece

-

Keyword:

-

Abrasive Media

-

MOQ:

-

one ton

-

Sample:

-

accept

-

Package:

-

25kg bags

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

12-100

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fenqiang

-

Model Number:

-

urea 60-100

-

Use:

-

Mass finishing polishing

-

Product name:

-

plastic media

-

Application:

-

Polishing Workpiece

-

Keyword:

-

Abrasive Media

-

MOQ:

-

one ton

-

Sample:

-

accept

-

Package:

-

25kg bags

Product Description

Fenqiang trading is a professional engaged in surface treatment of polymer plastic media ( resin sand ) research and development, production, sales of high-tech enterprises.

At present, the enterprises introduces advanced production equipment from the United States, precision testing instruments from Germany, the most advanced production technology in Japan, and gentle Japanese production and management concept. The products are widely used in electronics deflashing, aviation, Mold cleaning,surface sealants, shipbuilding industry, automobile, motor car, machinery manufacturing, coating removal,rubber,fller, paint remover, reinforcing agent, water releasing agent, flame retardant and other industries. The product has passed MIL-P-85891 certification.

In addition, we also export WA, BFA, PA, SIC, GC, steel shot, steel grit and other abrasive products.

At present, the enterprises introduces advanced production equipment from the United States, precision testing instruments from Germany, the most advanced production technology in Japan, and gentle Japanese production and management concept. The products are widely used in electronics deflashing, aviation, Mold cleaning,surface sealants, shipbuilding industry, automobile, motor car, machinery manufacturing, coating removal,rubber,fller, paint remover, reinforcing agent, water releasing agent, flame retardant and other industries. The product has passed MIL-P-85891 certification.

In addition, we also export WA, BFA, PA, SIC, GC, steel shot, steel grit and other abrasive products.

Specification

|

item

|

value

|

|

Warranty

|

3 years

|

|

Type

|

blasting media

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

Fenqiang

|

|

Model Number

|

|

|

Usage

|

Mass finishing polishing

|

|

Abrasive Grain Sizes

|

12-16

|

|

Product name

|

plastic media

|

|

Application

|

Polishing Workpiece

|

|

Keyword

|

Abrasive Media

|

|

MOQ

|

one ton

|

|

Sample

|

accept

|

|

Package

|

25kg/bag

|

Technical Data

Application

Aircraft paint removal:

Removes most types of paint from typical aircraft substrates, while leaving anodized and alclad surfaces intact. Is employed on a

wide variety of off-aircraft components -resulting in significant savings over chemicals.

Burr removal:

Removes light burrs from components while maintaining integrity of finished part.

Composite Structures:

Can strip paint and surface coatings from fiberglass, carbon-graphite, epoxy, and other resin rich components without bloom or

fiber damage.

Electronics deflashing:

Used both in dry and wet blast to remove flash from electronic components and for surface preparation of PCB's.

Boats:

Bottom paint stripping from aluminum, fiberglass and dense hardwood hulls. Rapid removal of dried barmacles. Cleans brass of

oxides and other coatings. Detects and exposes blisters on fiberglass hulls.

Clear epoxy optical sensors:

Only media capable of removing resin bleed without opaquing surface. Eliminates individual time-consuming masking requirements.

Die Casting:

Removes light flash from cast components without affecting critical surface dimensions.

Encapsulated electronic parts:

Will not damage delicate parts or mar surfaces. Leaves product surface smear free, ready for identification printing or soldering.

Engine components:

Carbon deposits and paint can be easily dry stripped with no wear to critical mechanical dimensions, including aluminum parts.

Lead frames:

Prepares lead for easier and more uniform tinning and coating procedures. Removes resin bleed without impinging surface.

Paint rejects:

Can be substituted for chemical stripping. In many applications, major time savings can be realized. Effective on most paint

systems including powder coating.

Surface preparation:

Etching circuit boards before printing. Pre-laminate roughening. Prepaint surface prep on plastics.

Ground vehicle paint removal:

Paint is readily removed from auto, truck, railcar, and bus bodies.

Mold cleaning:

Readily cleans molds used in rubber, plastic, glass, and die cast molding without affecting surface dimensions. Edges are not

radiused, mold life is prolonged, cracks in molds are not smeared over, and flash on parts is reduced.

Plastic molded parts:

Effectively removes flash from parting lines on thermoset plastic parts. Removes surface anomalies without damage to the part.

Surface sealants:

Tenacious sealants and adhesives can be safely removed without damage to the substrate.

Removes most types of paint from typical aircraft substrates, while leaving anodized and alclad surfaces intact. Is employed on a

wide variety of off-aircraft components -resulting in significant savings over chemicals.

Burr removal:

Removes light burrs from components while maintaining integrity of finished part.

Composite Structures:

Can strip paint and surface coatings from fiberglass, carbon-graphite, epoxy, and other resin rich components without bloom or

fiber damage.

Electronics deflashing:

Used both in dry and wet blast to remove flash from electronic components and for surface preparation of PCB's.

Boats:

Bottom paint stripping from aluminum, fiberglass and dense hardwood hulls. Rapid removal of dried barmacles. Cleans brass of

oxides and other coatings. Detects and exposes blisters on fiberglass hulls.

Clear epoxy optical sensors:

Only media capable of removing resin bleed without opaquing surface. Eliminates individual time-consuming masking requirements.

Die Casting:

Removes light flash from cast components without affecting critical surface dimensions.

Encapsulated electronic parts:

Will not damage delicate parts or mar surfaces. Leaves product surface smear free, ready for identification printing or soldering.

Engine components:

Carbon deposits and paint can be easily dry stripped with no wear to critical mechanical dimensions, including aluminum parts.

Lead frames:

Prepares lead for easier and more uniform tinning and coating procedures. Removes resin bleed without impinging surface.

Paint rejects:

Can be substituted for chemical stripping. In many applications, major time savings can be realized. Effective on most paint

systems including powder coating.

Surface preparation:

Etching circuit boards before printing. Pre-laminate roughening. Prepaint surface prep on plastics.

Ground vehicle paint removal:

Paint is readily removed from auto, truck, railcar, and bus bodies.

Mold cleaning:

Readily cleans molds used in rubber, plastic, glass, and die cast molding without affecting surface dimensions. Edges are not

radiused, mold life is prolonged, cracks in molds are not smeared over, and flash on parts is reduced.

Plastic molded parts:

Effectively removes flash from parting lines on thermoset plastic parts. Removes surface anomalies without damage to the part.

Surface sealants:

Tenacious sealants and adhesives can be safely removed without damage to the substrate.

Hot Searches