- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5500x1800x2200mm

-

Weight (KG):

-

1500

-

Warm-up time:

-

15-30min (180°C)

-

Max. temperature:

-

250°C

-

Operation:

-

easy to operate

-

Application:

-

Surface Treatment

-

Door:

-

2

-

Coating color:

-

Customized

Quick Details

-

Machine Type:

-

Powder Paint Oven, Drying Oven, Curing oven, Drying Oven, Curing oven, Powder Paint Oven

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

110V/220V/380V/customized

-

Dimension(L*W*H):

-

5500x1800x2200mm

-

Weight (KG):

-

1500

-

Warm-up time:

-

15-30min (180°C)

-

Max. temperature:

-

250°C

-

Operation:

-

easy to operate

-

Application:

-

Surface Treatment

-

Door:

-

2

-

Coating color:

-

Customized

Product Description

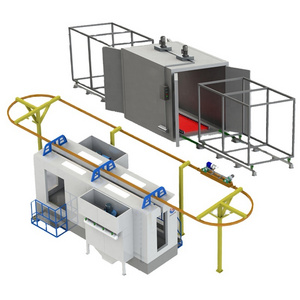

Industrial Powder Paint Curing Oven With Overhead Conveyor Track

This gas oven internal size and type can be designed and manufactured according to client's workpiece feature and output etc requirement.

1.heating up time is quickly 15-25mins

2. high efficiency

3.save cost and energy

4.overhead rails optional

5.ground track design optional

6.operate easily

The oven project was designed for our Australia customer

who supply the powder coating service to all kinds of metal parts. And this equipment asked for heavy bearing for the rail, and bigger production, so we designed for the top sliding trolley type.

|

Specifications

|

|

|

|

Model

|

AL-202G

|

|

|

Working Chamber Size

|

customized

|

|

|

Wall Insulation

|

100% new rock wool board,100 mm thickness

|

|

|

Heating Temperature & Time

|

180° C (15-30min) Max250° C

|

|

|

Temperature Stability

|

< ± 3-5°C

|

|

|

Voltage/ Frequency

|

110V/380V (50-60hz), customized as local

|

|

|

Heating Source

|

Gas

|

|

|

Motor Power

|

5.5 KW

|

|

|

Circulation / Air Flow

|

Vertical ,Variable through holes on the walls

|

|

|

Transportation

|

Conveyor on top

|

|

Gas Burner

Equipped with a high-performance imported Riello burners takes full utilization of fuels, gives much quicker raise to a required temperature comparing with electric heating, as well as more environmental-friendly than diesel fired oven.

Circulation Fan

The main function of circulation fan is to ensure the uniform temperature in oven chamber.

When the heating element creates hot air the circulation fan cycles the heat through entire chamber and ensures workparts to be heated evenly.

Controller

The user-friendly panel gives you an easy access to set heating temperature, time and working of fan.

Once the curing time arrive, the oven will stop heating automatically. Simple and low fault rate.

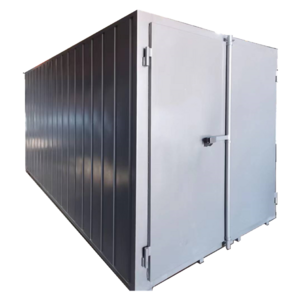

Oven Chamber

Oven wall interlayer material is 100mm thick rockwool board, built with heat-resistent galvanized innerwall and durable color steel outwall to form a sandwich insulation structure. This is an optimum design to maintain the temperature in oven chamber.

Gas oven with Overhead Conveyor Track is part of our manual coating line.

How we make the curing oven :

1.The outer layer of the oven is formed by folding the edges and corners of galvanized sheet ,increasing the firmness

2.Fill in the middle with 2 layers of rock wool, getting a thickness of 100mm.

3.Make the inner layer the oven

4.The door frame is made of bent 2.5mm iron plate.

Taizhou Ailin Trade Co.,Ltd

is located in the famous historic and cultural city---LinHai city of ZheJiang Province.

We own 2

factories

in local

. We have been committed to manufacturing, supplying and exporting automatic powder coating line, powder spray booth,curing oven ,

powder coating machines , electrostatic spray guns and gun spare parts

more than 10 years. Our customers are from China, UK,A

me

rica,South Africa,Indonesia,Vietnam,Brizal,Chile...We have a strong technical team,product department and after service team. All the customers and friends are welcome to visit our factory!

Our Services & Strength

Each piece of equipment is built to meet your specific needs. Also make sure you get the best results.Enable our customers to catch up the latest equipment, increase profits and maintain their competitiveness in the word of trade.

FAQ

|

How to delivery?

|

|

By sea for big order ,by courier for small order ,by airlines.

|

|

Which model should I choose?

|

|

When spray specially metallic powders, according to your product shapes and the coating job details. For example, need to change colors often or only few colors, then choose the box feed unit or hopper feed unit. The small hopper unit is good for lab test or small work.

|

|

Can I customized the machines?

|

|

Yes, we are a professional team for powder coating equipments, Our technician will design for you specially according to your needs and your factory, workpiece etc information.

|

|

What should I offer if I want to customized the machine?

|

|

a. Your factory available for the equipment dimension by L x W x H

|

|

b. Your max workpiece or product weight and size by L x W x H

|

|

c. Your product surface condiation(with oil or dust?) and some pictures if possible.

|

|

d. Your output capacity(for machine line)

|

|

e. Your industrial electric power in V-Phase-Hz.

|

|

Can you install for us?

|

|

we will guide you step by step through blueprint and vedio.

we also can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

|

Hot Searches