- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.1 mm

-

Travel (X Axis)(mm):

-

3000 mm

-

Travel (Y Axis)(mm):

-

2000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

4.5kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MISHI

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

3700mm*2200mm*1800mm

-

Weight (KG):

-

2300

-

Product name:

-

Bridge cutting machine

-

Application:

-

Stone Marble Granite Quartz Sandstone

-

Keywords:

-

Stone CNC Cutting Machine Saw

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Stone Engraving Carving Cutting

-

Transmission:

-

TBI Ball Screw

-

Working area:

-

2000x3000mm

-

Guide rail:

-

Taiwan Hiwin Guide Rail

-

Color:

-

Customer Needing

-

Structure:

-

Heavy Duty

Quick Details

-

Working Table Size(mm):

-

2000×3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

0 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.1 mm

-

Travel (X Axis)(mm):

-

3000 mm

-

Travel (Y Axis)(mm):

-

2000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

4.5kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MISHI

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

3700mm*2200mm*1800mm

-

Weight (KG):

-

2300

-

Product name:

-

Bridge cutting machine

-

Application:

-

Stone Marble Granite Quartz Sandstone

-

Keywords:

-

Stone CNC Cutting Machine Saw

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Stone Engraving Carving Cutting

-

Transmission:

-

TBI Ball Screw

-

Working area:

-

2000x3000mm

-

Guide rail:

-

Taiwan Hiwin Guide Rail

-

Color:

-

Customer Needing

-

Structure:

-

Heavy Duty

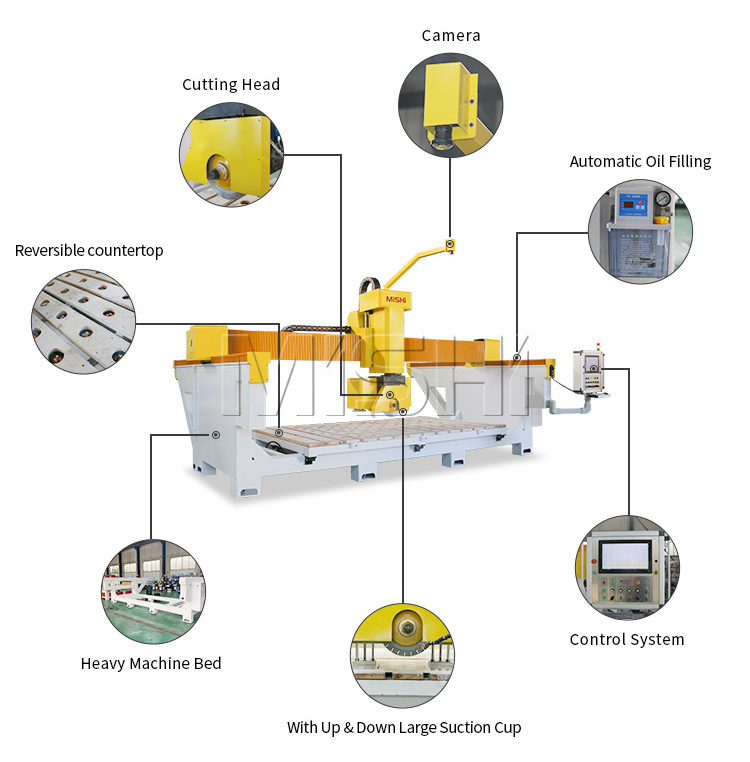

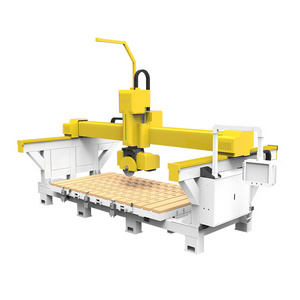

Product Show

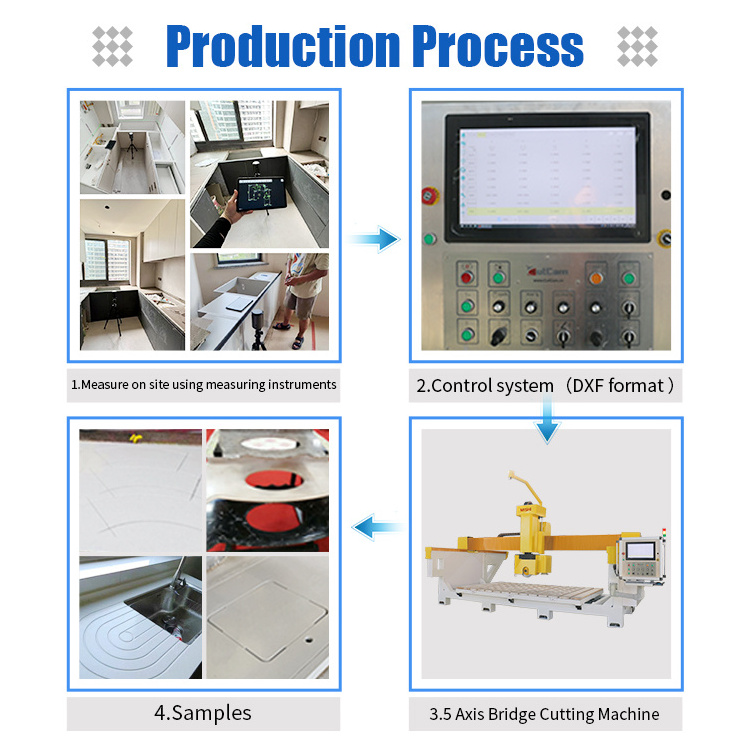

This stone CNC machining center can cut quartz, marble, granite, and rock slabs with a powerful saw blade. It combines a saw blade and CNC router tools to achieve multiple advanced functions. For example, cutting and milling straight and inclined edges, chamfering, cutting arc edges, polygon, edge milling, edge tracking, and other powerful functions. The 5 axis bridge saw is widely used in the stone processing plants, kitchen countertop processing, background wall profiling, and other fields.

Technical Parameters

|

CNC Stone Bridge Saw Machine

|

|

|

|

model

|

CNC Stone Bridge Saw Machine

|

|

|

X, Y, and Z

|

3200*2000*400mm

|

|

|

C axis

|

±360°

|

|

|

Moving speed

|

Xaxis 30m/min Yaxis 30m/min Zaxis 15m/min

|

|

|

Servo motor

|

X and Y 1300W absolute servo motor Z axis 1300W absolute servo motor with brake A and C 1000W absolute servo motor

|

|

|

Guide rail

|

X, Y, and Z: # 30

|

|

|

Spindle

|

mechanical spindle,10000RPM,with BT40

|

|

|

Rack

|

X、Y 2MT-WIN

|

|

|

Worktable

|

Structure Square timber Worktable size 3200×2000mm Turning angle 0-80° Max. weight for turning 800KG

|

|

|

Reducer

|

X/Y: Japan SHIMPO

|

|

|

Saw motor

|

11KW motor, rated: 3000r/min

|

|

|

Control system

|

Customized system (built-in CAM software)

|

|

|

Low-voltage electronics

|

French SCHNEIDER

|

|

|

Working air pressure

|

0.7-0.8Mpa

|

|

|

Voltage

|

380V/3P/50HZ

|

|

|

* The size, color, configuration and design can all be customized according to customer's requirements

|

|

|

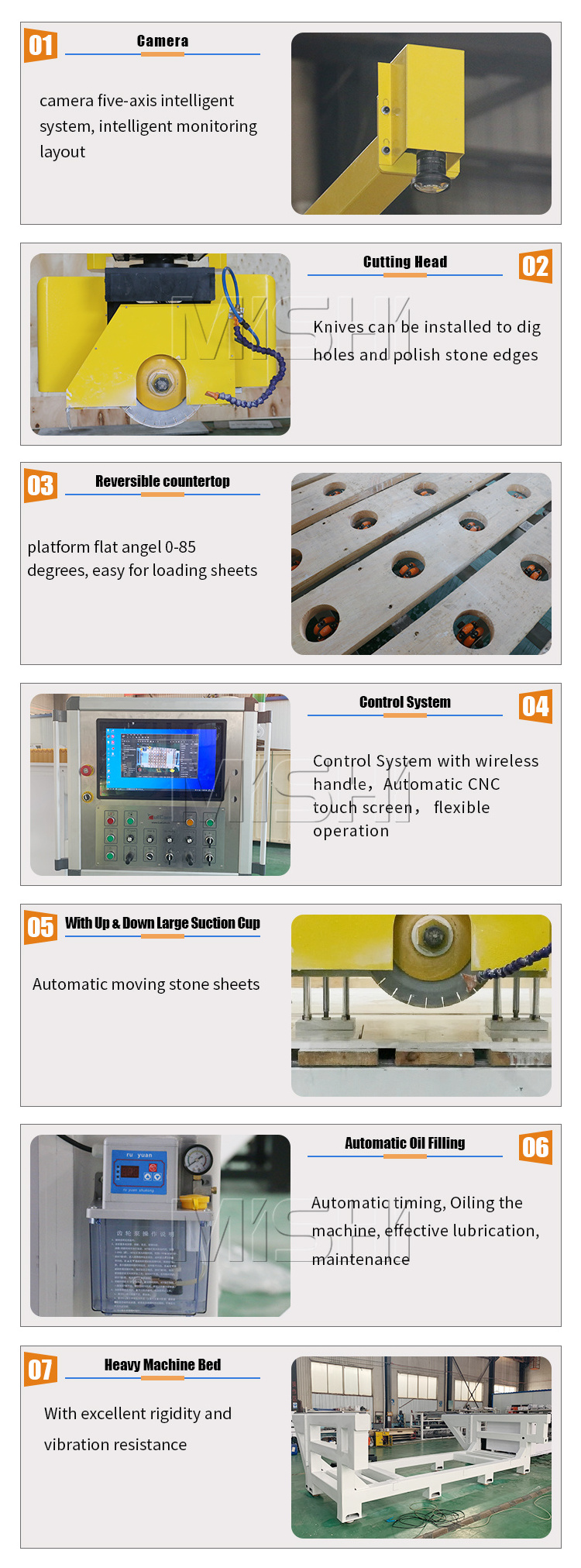

Details Images

Application

Suitable for drilling, sanding, edging, and carving on artificial stone, quartz stone, marble, granite, ceramics, glass, ceramic stones, and other anomalous stones.

In addition, it is suitable for making cabinets, countertops, sinks, European-style edging, splashbacks, and so on.

Stone CNC machine is used for granite, marble, jade, sapphire, artificial stone, tombstones, milestones,and other types of stone processing, the stone cutting machine can achieve various processing functions, 3D relief, and line carving, bevel cutting, drilling 2D processing. Such as lettering (pattern), relief, image carving, cutting, etc. Simple operation, low energy consumption, low noise, high efficiency, and high precision. Widely used in inscriptions, stone carving, construction, decoration,kitchen and bathroom, furniture, signs, handicrafts, and other industries.

In addition, it is suitable for making cabinets, countertops, sinks, European-style edging, splashbacks, and so on.

Stone CNC machine is used for granite, marble, jade, sapphire, artificial stone, tombstones, milestones,and other types of stone processing, the stone cutting machine can achieve various processing functions, 3D relief, and line carving, bevel cutting, drilling 2D processing. Such as lettering (pattern), relief, image carving, cutting, etc. Simple operation, low energy consumption, low noise, high efficiency, and high precision. Widely used in inscriptions, stone carving, construction, decoration,kitchen and bathroom, furniture, signs, handicrafts, and other industries.

1. It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket.

This ensures good stability and flexibility during operation.

2. This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

3. It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

4. The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

5. This bridge saw is ideal for cutting slabs of quartz, marble, granite and stone.

This ensures good stability and flexibility during operation.

2. This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

3. It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

4. The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

5. This bridge saw is ideal for cutting slabs of quartz, marble, granite and stone.

After Sales Services

Hot Searches