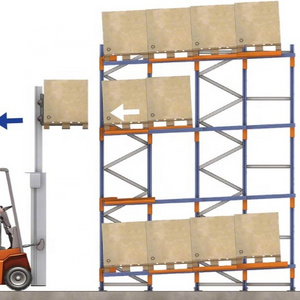

Loading

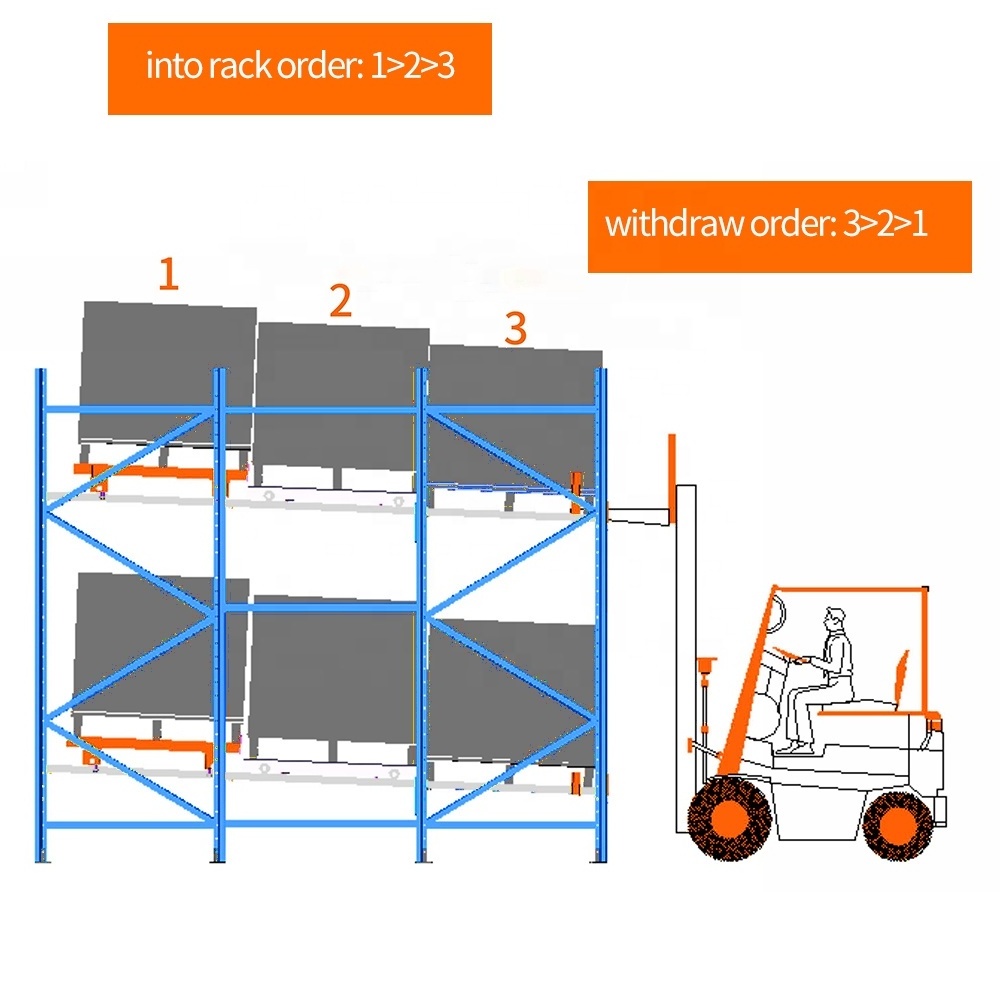

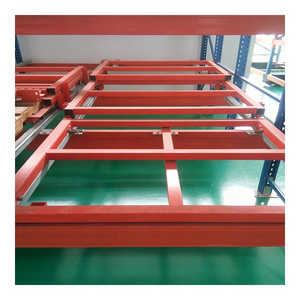

Carrying cart runs along the inclined support rail. 1st pallet is placed on the carrying cart, 2nd pallet pushed back 1st pallet

into the rack, 3rd pallet push the front 2 pallets into rack, the rest keep the same operation.

into the rack, 3rd pallet push the front 2 pallets into rack, the rest keep the same operation.

Unloading

Pallet at the pick-up end is carried out first, the next pallet slides to the pick-up point by gravity for unloading, other keep

the same.

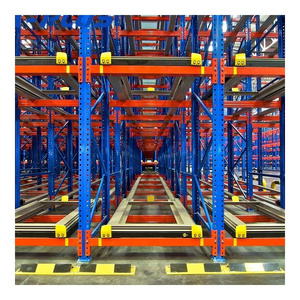

Unlike drive in pallet rack, forklift truck don’t drive into the rack

Pallet at the pick-up end is carried out first, the next pallet slides to the pick-up point by gravity for unloading, other keep

the same.

Unlike drive in pallet rack, forklift truck don’t drive into the rack