- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110v/220v380v

-

Power:

-

3kw/4hp

-

Weight:

-

120 KG, 120kg

-

Dimension(L*W*H):

-

600*500*1200mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

color:

-

red,green or as customer required

-

capacity:

-

400kg/h

-

Keywords:

-

Small Flour Milling Machine

-

Operation:

-

Easily

-

Function:

-

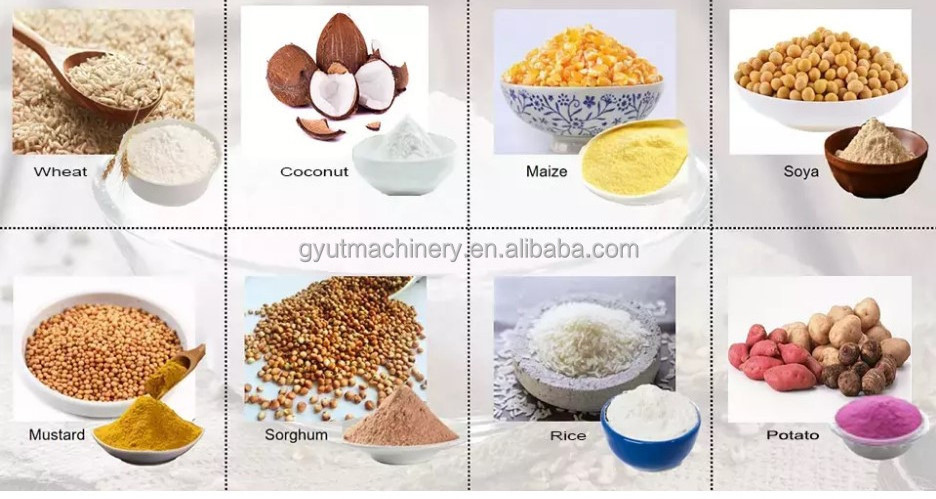

Maize Flour Milling Machine

-

Used for:

-

Grain Flour Milling

-

Application:

-

Grain Processing Line

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UT Machinery

-

Production Capacity:

-

98%

-

Voltage:

-

110v/220v380v

-

Power:

-

3kw/4hp

-

Weight:

-

120 KG, 120kg

-

Dimension(L*W*H):

-

600*500*1200mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

color:

-

red,green or as customer required

-

capacity:

-

400kg/h

-

Keywords:

-

Small Flour Milling Machine

-

Operation:

-

Easily

-

Function:

-

Maize Flour Milling Machine

-

Used for:

-

Grain Flour Milling

-

Application:

-

Grain Processing Line

-

Certification:

-

ISO

Corn Maize Flour Milling Machine

Parameters for Automatic maize corn wheat rice flour milling machine

Wheat skin and wheat core are milling independently in this milling machinery.

The raw material enter the machine are grinded for 4-5 times , the flour out ,the skin will be continue grinded ,the flour out, the skin out. Next grinding the core for some times, the flour out.

Main Technical specifications:

|

model |

UT-90 |

|

capacity |

300kg/h(based on maize) 400kg/h(based on wheat) |

|

power |

3-4kw |

|

main rotation speed |

1200RPM |

|

weight |

120kg |

|

size |

600*500*1200mm |

Pictures of grain flour Mill machine:

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Pre-sale:

1. Suggest to client suitable models of the rice transplanting machine

.

2. Introduce machine's structure and features in detail, explain the price component;

3. answer client concerned questions.

After-sale:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring" your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.