- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1420*1450*1350

-

Weight (T):

-

1.1 T

-

Power (kW):

-

800

-

Certification:

-

ISO

-

Input Current:

-

370A

-

power consumption:

-

<580KWH/T

-

Output DC current:

-

460A

-

Rated frequency:

-

700Hz

-

Power factor:

-

0.95

-

Output DC voltage:

-

1750V

-

Melting speed:

-

<45min

-

Maximum output voltage:

-

2500V

-

Product Name:

-

copper ore smelting furnace

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHENNAI

-

Voltage:

-

660V*2

-

Dimension(L*W*H):

-

1420*1450*1350

-

Weight (T):

-

1.1 T

-

Power (kW):

-

800

-

Certification:

-

ISO

-

Input Current:

-

370A

-

power consumption:

-

<580KWH/T

-

Output DC current:

-

460A

-

Rated frequency:

-

700Hz

-

Power factor:

-

0.95

-

Output DC voltage:

-

1750V

-

Melting speed:

-

<45min

-

Maximum output voltage:

-

2500V

-

Product Name:

-

copper ore smelting furnace

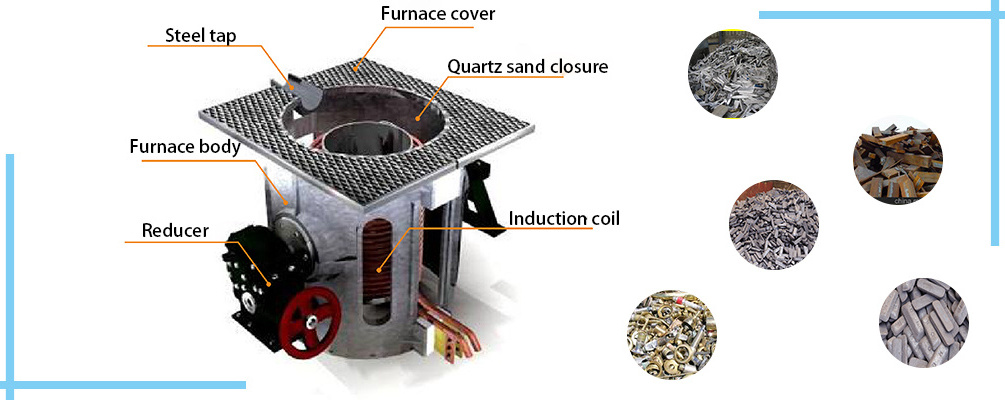

copper ore smelting furnace

SHENNAI factory is specialized in producing melting furnaces for various metals,alloy,copper, steel, aluminum and iron.If you have lots of metal scrap don't know produce what product. welcome to contact with us,we will supply you one suggestion.Moreover, we can customize the furnace suitable for your production according to your needs.

Following is our induction melting furnace features:

- Induction melting furnace power can adjust under different melt capacity requirement.

- Fast melt speed.Can melt Waste iron,steel,copper,aluminum,aluminum cans ,lead,etc all kinds of metals.

- Steel and Aluminum structure furnace body design.Work stable.

- Machine have multiple protection.With Good magnetic isolation,safe and reliable.

- Induction melting furnace are most used in foundry factory,rolling mill etc.

- Induction melting furnace are customized under customer's workshop size.and working environment ,customer's special requirement.

- Machine most used in foundry factory,to use the waste iron recycling to produce ingots.

Contact us for more information

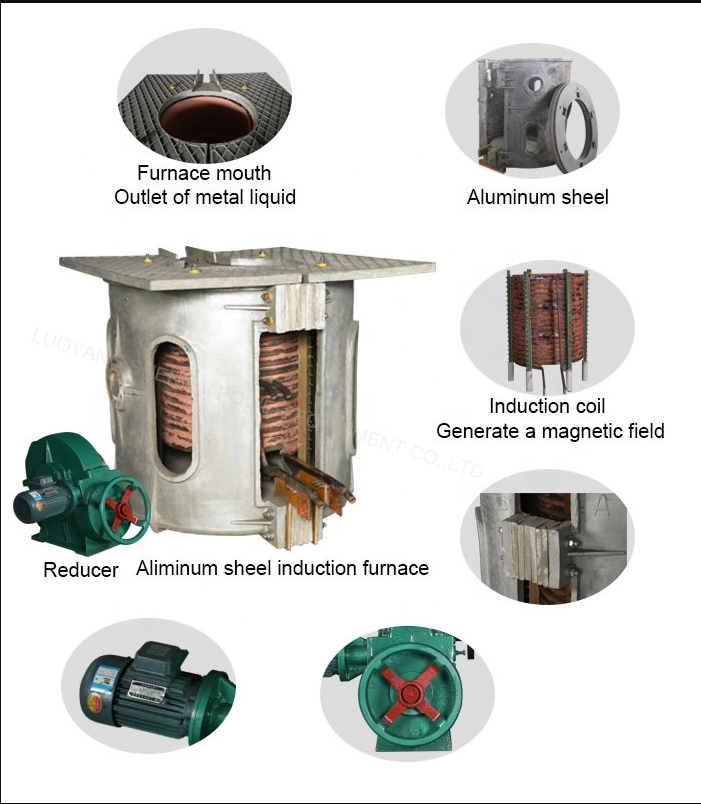

Advantages of aluminum shell induction melting furnace :

- High melting efficiency, good power saving effect, compact structure and strong overload capacity.

- The surrounding of the furnace is low temperature, smoke less, the working environment is good .

- Simple operation and reliable operation.

- Fast temperature heating-up, furnace temperature easy to control, high production efficiency.

- High efficiency and energy consumption less than 550KWH/T

- Selenium steel made of magnetic yoke of the magnetic field lines generated by the induction coil has played the role of shielding emission to reduce the magnetic leakage so that it improves the efficiency and energy saving is 5%~8%.

- Electronic components using well-know brands at home and abroad.

-

Long arc yoke shield and reduced external magnetoresistance,shielding leakage at both ends of the coils,The inner side and outer wall of the magnetic yoke(arc section ) are in close contact with each other ,increased the area of effectivepermeability.So that the coils is better supported.

Technical Parameter:

Please contact me for customized parameters

|

Model (KGPS) |

Rated Power(kw) |

Frequency (Hz) |

Input Voltage(V) |

Max current(A) |

Furnace Capacity (T) |

Power consumption (kw.h/T) |

Transformer Capacity (KVA) |

Cooling water Capaciyy (T/H) |

| KGPS-250/1 | 250 | 1000 | 380 | 600 | 0.3 | 670 | 300 | 20 |

| KGPS-350/1 | 350 | 900 | 0.5 | 670 | 400 | 20 | ||

| KGPS-500/1 | 500 | 1200 | 0.75 | 640 | 600 | 25 | ||

| KGPS-750/1 | 750 | 1500 | 1 | 620 | 800 | 30 | ||

| KGPS-750/0.7 | 750 | 700 | 660 | 1100 | 1 | 600 | 1000 | 40 |

| KGPS-1000/0.7 | 1000 | 1500 | 1.5 | 580 | 1500 | 50 | ||

| KGPS-1500/0.5 | 1500 | 500 | 1800 | 2 | 570 | 1800 |

60 |

|

| KGPS-2000/0.5 | 2000 | 950 | 1800 | 2.5 | 550 | 2500 | 70 | |

| KGPS-3000/0.5 | 2500 | 2500 | 3 | 530 | 3150 | 80 | ||

| KGPS-4000/0.5 | 4000 | 3600 | 5 | 530 | 4000 | 100 | ||

| KGPS-4500/0.5 | 4500 | 4000 | 6 | 600 | 5000 | 120 | ||

| KGPS-6000/0.5 | 6000 | 2625*2 | 8 | 580 | 6300 | 150 | ||

| KGPS-8000/0.5 | 8000 | 300 | 3300*2 | 10 | 570 | 8000 | 160 | |

| KGPS-9000/0.5 | 9000 | 1800*4 | 12 | 560 | 9000 | 180 | ||

| KGPS-10000/0.5 | 10000 | 2000*4 | 15 | 550 | 10000 | 200 | ||

| KGPS-12500/0.3 | 12500 | 2500*4 | 20 | 540 | 12500 | 240 | ||

| KGPS-15000/0.3 | 15000 | 3000*4 | 25 | 540 | 15000 | 245 | ||

| KGPS-16000/0.3 | 16000 | 3200*4 | 30 | 530 | 16000 | 250 |

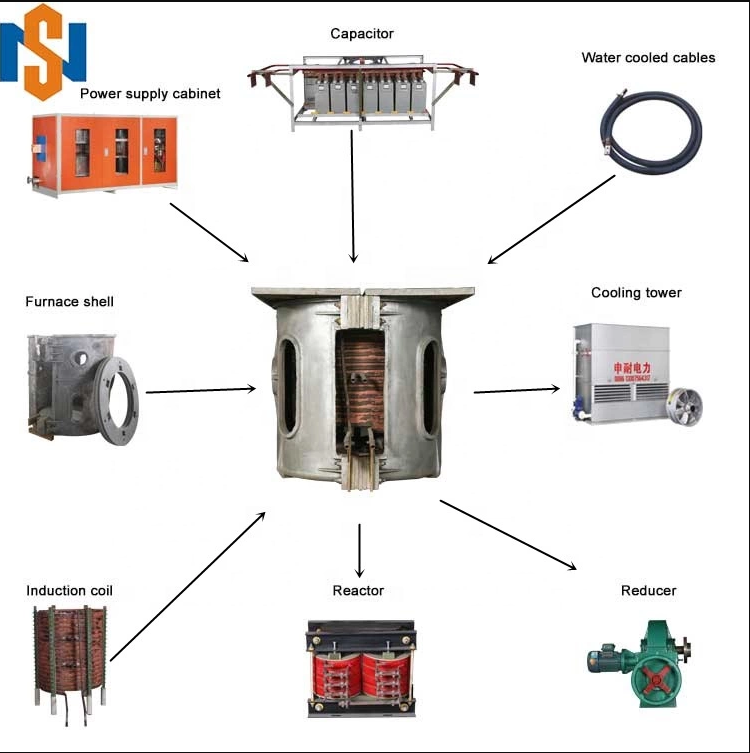

Display of steel shell induction melting furnace:

| Type/Model | Steel shell series medium frequency induction melting furnace |

| Manufacturer | Luoyang Shennai Power Equipment Co.,Ltd. |

| Brand | Shennai |

| Components | Reducer, Furnace body, Induction coil, |

| Supporting facilities | Power supply Cabinet, Closed type cooling tower, Reducer,H ydraulic pressure station |

| Quality Standard | ISO 9001 |

| Melting Materials(Main) | Aluminum,steel,iron,copper,brass,gold,sliverand other metals. |

| Capacity | 100kg-15ton, Can be costomized according to ures needs. |

| Losding port | Any port of China. |

Please click here for detail communication

Related Products:

Related Question:

- What kind of metal do you want to melt?

- The melting capacity is ton?

- The melting speed is min/batch?

Click here to fill out your inquiry in the txet box to get the lasted quotation.